Avto-Science.ru

The Multitronic variator (trademark Multitronic ) is the most advanced continuously variable transmission to date. The use of this box ensures maximum vehicle dynamics, high engine fuel efficiency and driving comfort. Due to its high consumer qualities, the CVT gearbox is installed on premium Audi (models A4, A5 and A6).

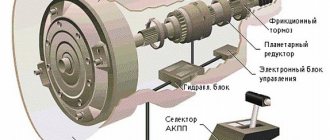

The Multitronic variator has the following device:

- multi-plate wet clutch;

- planetary mechanism;

- intermediate gear;

- variator (variable transmission);

- main gear;

- differential;

transmission control system- gearbox housing.

Multitronic gearbox diagram

The function of separating the engine from the gearbox in the Multitronic system is performed by two wet (working in oil) multi-plate clutches . Clutches are multi-plate friction clutches - clutches: forward clutch and reverse clutch. The design of friction clutches is similar to the clutches used to change gears in automatic transmissions.

The gearbox provides forced cooling of the clutches with a separate flow of working fluid. Friction clutches have significant advantages over a torque converter that performs a similar function. They are lighter, compact and easier to manage.

The planetary mechanism is used only for reversing. When the vehicle moves forward, the gearbox is blocked by the forward clutch. When moving backwards, the reverse clutch locks the gearbox ring gear onto the gearbox housing, as a result of which the planetary gearbox moves in the opposite direction. Reverse speed is limited by the control system.

The variator provides a smooth change in gear ratio. It consists of the following structural elements:

- drive pulley;

- driven pulley;

- chain.

Each pulley consists of two disks with a conical surface. The drive disk is connected to the engine crankshaft through an intermediate gear. From the driven disk, torque is directed to the main gear. One of the disks on each pulley is movable. This allows you to change the diameter of the pulley during operation.

The Multitronic variator uses a metal chain . This technical solution made it possible to significantly expand the range of gear ratios by reducing the contact surface of the chain with the pulley (compared to a V-belt). Reducing noise during operation of a metal chain is achieved by using links of different sizes.

The drive of each pulley consists of two hydraulic cylinders - pressing and adjusting. The hydraulic pressure cylinder directly presses the chain against the pulley discs. The adjusting hydraulic cylinder ensures a change in the diameter of the pulley, i.e. regulates the gear ratio. The force with which the discs are pressed against the chain is controlled by a torque sensor . The sensor is installed on the drive disk.

Since the Multitronic CVT is installed on front-wheel drive vehicles, the final drive and differential are included in the gearbox design.

transmission control system

- hydraulic control unit;

- input sensors;

- electronic control unit.

The hydraulic control unit directly controls the forward and reverse clutches, pressure and adjustment cylinders, regulates the pressure of the working fluid in the system, and also cools the clutches. The hydraulic block contains:

- manual control spool;

- hydraulic valves;

- pressure control solenoid valves.

The circulation of the working fluid in the system is ensured by oil pump , which is driven by the input shaft. To cool the clutches, an ejection pump , the operation of which is based on the supply of working fluid due to vacuum. The working fluid is cooled in an oil-water heat exchanger included in the engine cooling system.

Transmission control system input sensors include

- selector lever position sensor;

- speed sensor at the gearbox input;

- speed sensor at the gearbox output;

- working fluid temperature sensor;

- working fluid pressure sensor.

The electronic control unit is used to select the optimal gear ratio in accordance with driving conditions and the desires of the driver. Based on the sensor signals, the electronic control unit calculates the pressure of the working fluid and realizes this pressure by acting on the solenoid valves. The control unit is installed directly on the gearbox.

The Multitronic variator has a mechanical connection with the selector lever . Transmission control modes are similar to automatic transmission modes. This box implements the “Kick-Down” , which involves rapid acceleration of the car. The Tiptronic fixed gear selection function is used.

World Of Man Dreams

The Multitronic CVT is a type of continuously variable transmission. The use of this box ensures maximum vehicle dynamics, high engine fuel efficiency and driving comfort. Due to its high consumer qualities, the CVT gearbox is installed on premium Audi (models A4, A5 and A6).

The Multitronic CVT consists of a multi-plate wet clutch, a planetary gear, an intermediate gear, a CVT gear, a final drive and a differential. The variator has its own electronic control system. All structural elements are placed in the gearbox housing.

The function of separating the engine from the gearbox in the Multitronic system is performed by two wet (oil-operated) multi-plate clutches. Clutches are multi-plate friction clutches - clutches: forward clutch and reverse clutch. The design of friction clutches is similar to the clutches used to change gears in automatic transmissions.

The gearbox provides forced cooling of the clutches with a separate flow of working fluid. Friction clutches have significant advantages over a torque converter that performs a similar function. They are lighter, compact and easier to manage.

The planetary mechanism is used only for reversing. When the vehicle moves forward, the gearbox is blocked by the forward clutch. When moving backwards, the reverse clutch locks the gearbox ring gear onto the gearbox housing, as a result of which the planetary gearbox moves in the opposite direction. Reverse speed is limited by the control system.

CVT transmission provides a smooth change in gear ratio. It consists of a driving and driven pulley connected by a chain. Each pulley consists of two disks with a conical surface. The drive disk is connected to the engine crankshaft through an intermediate gear. From the driven disk, torque is directed to the main gear. One of the disks on each pulley is movable. This allows you to change the diameter of the pulley during operation.

The Multitronic variator uses a metal chain for the first time. This technical solution made it possible to significantly expand the range of gear ratios by reducing the contact surface of the chain with the pulley (compared to a V-belt). Reducing noise during operation of a metal chain is achieved by using links of different sizes.

The drive of each pulley consists of two hydraulic cylinders - pressing and adjusting. The hydraulic pressure cylinder directly presses the chain against the pulley discs. The adjusting hydraulic cylinder ensures a change in the diameter of the pulley, i.e. regulates the gear ratio. The force with which the discs are pressed against the chain is controlled by a torque sensor. The sensor is installed on the drive disk.

Since the Multitronic CVT is installed on front-wheel drive vehicles, the final drive and differential are included in the gearbox design.

The transmission control system includes input sensors, an electronic control unit and a hydraulic unit as an actuator.

The control system's input sensors evaluate selector lever positions, transmission input speed, transmission output speed, and fluid temperature and pressure.

The electronic control unit is used to select the optimal gear ratio in accordance with driving conditions and the desires of the driver. Based on the sensor signals, the electronic control unit calculates the pressure of the working fluid and realizes this pressure by acting on the solenoid valves. The control unit is installed directly on the gearbox.

The hydraulic control unit directly controls the forward and reverse clutches, pressure and adjustment cylinders, regulates the pressure of the working fluid in the system, and also cools the clutches. The hydraulic block contains the following actuators: manual control spool, hydraulic valves and pressure control solenoid valves.

The circulation of the working fluid in the hydraulic system is ensured by a gear-type oil pump, which is driven by the input shaft of the box. To cool the clutches, an ejection pump is used, the operation of which is based on the supply of working fluid due to vacuum. The working fluid is cooled in a heat exchanger included in the engine cooling system.

The Multitronic variator has a mechanical connection with the selector lever. Transmission control modes are similar to automatic transmission modes. This box implements the “Kick-Down” mode, which involves rapid acceleration of the car. Uses Tiptronic fixed gear selection function

The advantage of a variator over other gearboxes is the ability to continuously change the gear ratio since it does not have fixed gears, as in a conventional automatic transmission. CVT gearboxes were made at one time by companies such as Toyota, Honda and some others. But Multitronic is much more complex in design and superior to all others in driving performance. If other automakers, due to their design, could install a variator on small-class cars with far from the most powerful engines, then Multitronic, capable of transmitting a sufficiently large torque to the wheels, is installed on cars with fairly powerful engines (an example of this is the Audi A8 with engine 3, 0 l with a torque of 300 Nm and transmission 01J). Audi is currently announcing a new generation of Multitronic gearbox, capable of transmitting up to 500 Nm. The main difference from competitors is that Audi abandoned the use of a multitronic belt drive in the box and used a metal chain that can withstand many times greater loads without changing its size.

Torque from the engine is transmitted via the input shaft to the input pulley; the change in gear ratio is controlled by a hydraulic unit with a pump and a Multitronic electronic control unit.

Multitronic works according to the following principle: torque is supplied to the input shaft from the engine using a gear through a 6 (models before 2006) or 7 (after 2006) disc clutch, which is controlled by an electronic control unit via a valve body. Next, the torque is transmitted through the chain to the output pulley and shaft, from where it goes through the drive to the wheels of the car. In this case, the transmission ratio through synchronously moving pulleys is constantly changing. This is again controlled by an electronic control unit. The electronic control unit (multitronic computer) is located directly in the gearbox and is mounted on the gasket, being, like all elements of the multitronic gearbox, in oil. This arrangement of the block made it possible to place all the sensors directly on it and get rid of a large number of wires. The control unit also contains a selector lever sensor (F125) for the gearbox selector. The selector, located in the cabin, is connected to the sensor purely mechanically, using a cable. The following sensors are mounted in the control unit:

-G182 - input shaft speed sensor

-G195 - output shaft speed sensor

-G196 - output shaft speed sensor -2-

-G93—transmission oil temperature sensor

-G193 — oil pressure sensor -1-, automatic transmission (pressure in the clutch line)

-G194 — oil pressure sensor -2-, automatic transmission (pressure pressure)

-N88-emergency pressure relief valve (see figure below).

Suitable oil for automatic transmission of Audi A4

Oil in ZF5HP19 (5 gears)

| Transmission oil in VAG automatic transmission Article: G052162A2 |

Transmission fluid in the Multitronic variator

| In the first generation variator 01J (0AN) Article: G 052 180 A2 | In the latest generation variator 0AW Article: G052516A2 |

DSG oil for Audi A4 (S-tronic) with all-wheel drive and front-wheel drive

| With DSG-7 gearbox (DL501) DSG transmission fluid Article number: G 052 529 | With DSG-7 gearbox (DL382-7Q and DL382-7F) Transmission fluid ATF Article number: G 055 549 A2 | With DSG-7 gearbox (DL382-7Q and DL382-7F) MTF Transmission Fluid G 055 529 A2 |

Peculiarities

How to set up a spray gun for painting a car

When choosing, you should pay attention to the ECU of the engine of your steel stallion, as they are divided into three types. All foreign-made cars have on-board computers, and therefore the owner of this car with this device in its own cabin will incur more foreign exchange losses, but we assure you that there is something to pay for it

All foreign-made cars have on-board computers, and therefore the owner of this car with this device in its own cabin will incur more foreign exchange losses, but we assure you that there is something to pay for.

So let's look at what functions on-board computers have. In this video, you will be introduced to the instructions for installing BC Multitronics.

First, every on-board vehicle is an electrical device. This device also takes on all the activities related to counting and providing information to the driver.

The BC display also shows all the information a driver needs when driving a vehicle.

Some are designed so that in the event of a breakdown of a certain internal part of the car. They will be able to work for her.

The functions that the Multitronics on-board vehicle has are quite different in nature. Any brand of on-board aircraft offers a huge number of different functions.

Customs clearance auto calculator. Read more information on our website.

Here you will find reviews about iridium spark plugs.

In this article, you will find a sample resume for a driver.

The Multitronics on-board computer has the following functions:

- Suitable for forty different protocols.

- Notifies about defects, and also deciphers the code of this error.

- It notifies you by voice when the car goes beyond the normal limits.

- It also names all the provided characteristics of programs in a voice.

- The amount of gasoline in the tank is indicated by voice, which is especially convenient at a gas station.

- This on-board computer also has the ability to keep track of trips on the car where it is installed.

- BC Multitronics has the ability to control the quality of gasoline poured into the tank.

- The device also closely monitors gasoline consumption.

- It has the ability to notify by voice about side lights that the driver forgot to turn off.

- Can provide optimal temperature in the car interior for its passengers.

Multitronics on-board computer

Comfort X10 Buy

Multitronics

Comfort X10

multitronics

-comfort-x-10 …

An important function for many drivers is monitoring the quality of the fuel poured into the tank. This device also has one excellent quality that distinguishes it from many other on-board computers; it saves gasoline.

After all, Multitronics itself regulates the required gasoline injection.

Also, with the help of BC Multitronics, you can increase the safety of your personal transport during parking.

Gearbox Audi A4 B6

When purchasing the A4, you can choose between a five-speed manual transmission, a new type of continuously variable automatic transmission (Multitronic) and an automated transmission with manual shifting (Tiptronic).

All forward gears in the five-speed gearbox are fully synchronized, the gear ratios of the individual stages are matched to the corresponding engine power.

Gears last a very long time. If, despite this, a malfunction occurs in the gearbox, it should be repaired in a workshop. Disassembling shafts and gears requires special tools and appropriate knowledge. Even workshops, as a rule, send gearboxes requiring repair to special enterprises.

Engine power is transmitted through the clutch to the primary (input) shaft of the gearbox. Five gears sit on this shaft (and another gear for reverse gear). These gears are constantly meshed with corresponding gears on the output shaft. The gears of both shafts rest on needle rollers, that is, there is no rigid connection between the shaft and the gear.

Gears and shafts Gears rotate freely until one of them, due to the inclusion of a gear, meshes with the corresponding gear on the other shaft. To do this, on each shaft, first, using a synchronizer locking ring, a rigid connection is made between the gear and the shaft, after which the gear sits rigidly on the shaft and can engage with the mating gear to transmit force. In order for the gears to mesh with each other, the rotation speeds of the shafts must match. For this purpose, part of one shaft slides along part of the other shaft through friction elements. Thanks to friction, the shaft that rotates faster is slowed down until both shafts begin to rotate synchronously.

Forward and reverse gears

The first three gears are downshifts. The fourth gear is direct, the engine speed is transmitted in approximately a 1:1 ratio. When engaging fifth gear, the transmission output shaft rotates faster than the engine crankshaft. Naturally, the car must also have reverse gear. To do this, an additional gear is located on each drive shaft, which changes the direction of rotation of the drive wheels to the opposite. When selecting a gear using the gearshift lever, the movements of the lever are transmitted through the gearshift rod to the shift segment, which is located on the gearbox.

Multitronic continuously variable transmission A vehicle equipped with the newly designed Multitronic transmission accelerates faster and consumes less fuel. In addition, the Multitronic transmission offers greater comfort than a five-speed manual transmission. The Audi Multitronic has undergone a number of changes, improvements and improvements, so it differs from previous CVTs. Thanks to optimally designed hydraulics, switching processes occur very dynamically and without inertial overruns. Thus, the disadvantages of previous CVTs (“rubber band effect” or “slipping clutch syndrome”) are a thing of the past. The shortcomings of previous CVTs are also eliminated thanks to regulatory regimes that have been partially revised. The aforementioned "rubber band effect" is eliminated by an electronic speed control system, which ensures dynamic driving performance while maintaining the same noise profile.

In addition, the electronics take part in the dynamic driving ratio control program 8 (DRP). Based on the way the driver presses the accelerator pedal, this program determines the driver’s desire - whether he wants to get maximum power from the engine, or, conversely, to save fuel. In the latter case, based on the multidimensional characteristic of the engine speed, which is stored in the memory device, switching to a low gear ratio occurs already at a speed of 60 km/h (overdrive gear). If the driver gives full throttle (sharply presses the accelerator pedal all the way), the electronic circuit immediately switches to a sporty driving characteristic and engages a gear ratio (reduction gear) such that the high revs required for maximum power are already achieved at low speeds. During normal driving, the electronics select the most suitable gear ratio between two extreme values, and, in contrast to the shift processes in a stepped automatic transmission, here all changes in gear ratios occur completely imperceptibly and without jerking. In addition, the electronics recognize uphill and downhill driving and help the driver by compensating the power or, conversely, increasing the braking torque during engine braking. The highlight of this program is the so-called “manual mode”; in this mode, six rigidly defined steps are switched in an additional rocker or using a lever on the steering wheel, and in this case the switching occurs smoothly, without jerking.

Operating principle of the variator

During the development of the Multitronic gearbox, Audi engineers were able to create a continuously variable transmission with the help of a new transmission element (the so-called leaf chain), which allows high forces and torques to be transmitted over a long period of time.

Moreover, this variator, in which the ratio between the maximum and minimum gear ratios is 6, is superior to all previous types of automatic transmissions in terms of the largest and smallest gear ratios. Thanks to the high maximum gear ratio, the variator, for example, makes starting easier and eliminates the need for a hydraulic torque converter.

Instead, Audi uses an oil-cooled multi-plate clutch, which not only eliminates the transmission losses typical of a torque converter, but also allows for different starting algorithms. These algorithms are selected electronically in accordance with the driver's intentions, which again are determined by the way he presses the accelerator pedal.

In addition, the hydraulics were designed in a special way. The variator used a double-plunger principle, thanks to the division of the oil flow between the high-pressure circuit and the cooling circuit, compared to a conventional design, a much smaller pump is required. This allows you to increase efficiency. gearboxes and improve the driving performance of the car.

Gearbox with magnesium housing

In addition to manual gearboxes with an aluminum housing, the Audi A4 also features gearboxes with a housing made of magnesium.

To avoid contact corrosion, use only genuine Audi parts (bolts and attachment parts). Damage resulting from contact corrosion is not covered by the warranty. A gearbox with a magnesium crankcase can be recognized by the inscription “Mg AI 9 Zn 1”, which is located on the left side of the box.

Oil volume in automatic transmission / DSG Audi A4

How many liters should I fill?

The volume of oil poured into the Audi A4 automatic transmission depends on the type of gearbox:

- Automatic – 5HP19: 10.5 liters.

- Multitronic (variator) of the first generation 01J (0AN): 7.5 liters primary volume, 5 liters when changing.

- Multitronic (variator) of the latest generation 0AW: 7 liters.

- A4 with all-wheel drive from 2008 to the end of 2020 DSG-7 DL501: 7.5 liters primary volume, 6.7 liters when changing.

- A4 with front-wheel drive with 2020 DSG-7 DL382-7F: ATF - 3.5 liters, MTF - 3.8 liters.

- A4 with all-wheel drive with 2020 DSG-7 DL382-7Q: ATF - 3.5 liters, MTF - 3.8 liters.

Related items:

Automatic – 5HP19:

- Filter: VAG 01V325429 or ZF 0501209251 (ZF filter comes with ring).

- O-ring: VAG 01V325443 or ZF 0501314578.

- Automatic transmission pan gasket: VAG 01V321371 or ZF 1056303031.

Multitronic (variator) 0AW:

- Variator drain plug: VAG WHT005623A.

- Lubrication system hose: VAG 0AW301685C.

- O-ring (2 pcs): VAG N90666003.

- Bolt for filter mounting (3 pcs): VAG WHT003157.

- External filter: VAG 0AW301516H.

DSG-7 DL501 (S-Tronic) robot:

- Filter element: 0B5 325 330 A.

For other “automatic transmissions”, changes in related elements are possible.