Car : Lada Kalina. Asks : Borisov Dmitry. The essence of the question : When starting off, the Lada Kalina twitches, why?

Hello, I have the following problem on my car: When I start driving, the car starts to jerk, sometimes I even feel small impacts. However, during a full trip I do not observe such a problem. I can’t even think what the reason is. Please tell me?

Why does the engine jerk at low and idle speeds?

So, if the car jerks at idle, there may be several reasons for such a malfunction. Most often, problems affect the ignition system and power supply system; less often, elements of the engine control system or parts inside the internal combustion engine fail.

- First of all, damage to the engine mounts should be excluded, since increased vibrations from the internal combustion engine in this case often occur precisely at idle. If everything is normal with the airbags, then twitching of the power unit may occur due to malfunctions of one cylinder.

- The most common cause is spark plugs, as well as high-voltage armored wires. Often, the spark plug may be damaged, dirty from carbon deposits, etc., as a result of which there is a spark on it, but it is very weak or unstable, and is supplied at the wrong angle.

Damage to the insulation of high-voltage wires when a spark “breaks through” also leads to similar symptoms in the form of motor twitching. The ignition coil, switch, ignition module, and distributor also deserve additional attention. Depending on which ignition system is installed on a particular engine, all its elements must be checked one by one.

- After diagnosing the ignition system, you need to move on to the fuel and air supply systems. As a rule, injection nozzles may be faulty or dirty. Fuel filters are also checked, and fuel lines should be inspected for leaks.

- Let us also add that in cases where the engine jerks at idle, you need to make sure that not only the fuel filter, but also the air filter is in good condition.

The fact is that if the air filter is dirty, the engine may not have enough oxygen to prepare the correct fuel-air mixture. The same is true in cases where airing occurs in the power system or excess air is sucked in at the inlet.

In any case, the mixture may turn out to be too rich or lean, and the normal and timely combustion of such a charge in the cylinder does not occur. At the same time, in such a situation, the spark plugs become even more covered with soot, and sparking further deteriorates.

- On injection engines, the cause of twitching at idle in some cases is the electronic engine control system (ECM). In such a situation, it should be taken into account that this system includes a whole group of various electronic sensors and actuators that exchange data with the controller (ECU).

- Another possible cause of engine jerking at idle is problems with the throttle valve and problems with the IAC (idle air control). The idle air control itself is a stepper motor that closes the channel for supplying air bypassing the throttle valve.

In case of incorrect operation and malfunction of the regulator, as well as in the accumulation of a large amount of dirt and carbon deposits on the damper, the idle speed becomes unstable. In this case, the engine not only jerks, but the idle speed often fluctuates greatly.

Such “floating” of revolutions can appear on a cold engine and disappear as it warms up. Also, in some cases, the speed jumps and floats both cold and hot. To solve the problem, you need to clean the throttle and also check the IAC. It is also important to consider that on many cars, after cleaning, it is also necessary to train the throttle valve.

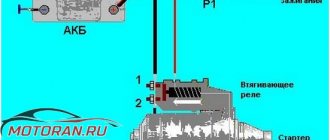

The main components of the distributor and a description of its operation

Which fuse is responsible for the generator VAZ 2107

VAZ classic distributor device

Device.

The distributor is assembled in a housing. Inside it, a contact group is mounted on a bearing: moving and fixed contacts or a Hall sensor (for contactless ignition). To correct the advance angle, the vacuum regulator can rotate the contact group at a small angle relative to the housing. The capacitor is attached to the bottom of the case with screws. A drive roller is mounted on bushings in the center of the body. Its bottom has splines with which it engages with the drive gear. In the upper part of the roller there are contact drive cams (for contact ignition) or a steel cup with four slots - a screen (for contactless ignition). At the very top, on a steel platform, two weights and two springs of the centrifugal ignition regulator are installed. A plastic housing with a moving contact and noise suppression resistance of the high voltage distributor (slider) is screwed onto the top with two screws. The entire structure is closed with a lid on two spring latches. The body and cover have a tongue and groove so that they fit together in only one position. The cover contains contact terminals for high voltage wires from the spark plugs and from the ignition coil. The distributor is secured to the engine block using a stud, nut and pressure washer. To adjust the ignition timing, the housing can be rotated relative to the block.

Job.

The distributor is connected through the drive to the engine crankshaft and rotates with it. For two full revolutions of the crankshaft, the distributor shaft makes one revolution. This is due to the fact that our engine is four-stroke. When installing the distributor in place, the roller is oriented in strict accordance with the operating order of the engine. This is done so that the contacts open and the spark jumps on the spark plug when the piston of each cylinder, compressing the combustible mixture, does not reach top dead center (TDC) by a few millimeters. This is called ignition advance. When the number of revolutions increases, the distance must be increased, and when it decreases, it must be decreased, which is what the centrifugal regulator does. Its weights, under the influence of centrifugal force, which is greater the higher the engine speed, diverge to the sides and move the cams relative to the roller, making ignition “earlier.” When the engine speed decreases, the springs return the weights to their place and the ignition becomes “later”. This is necessary to increase engine power and efficiency. In addition to the centrifugal one, a vacuum ignition timing regulator is also installed on the distributor. Its function is to fire “earlier” at low throttle opening angles and “later” at sharp throttle opening angles. At idle and at full throttle, the vacuum seal does not work. The regulators are adjusted only at the stands, so there is no need to change the settings yourself.

Useful tips

Quite often, engine jerking at idle can occur precisely when the internal combustion engine is cold. In this case, you should pay special attention to the motor temperature sensor.

Failure or malfunctions in its operation often lead to the ECU receiving a premature signal to warm up the power unit, while the engine is still cold.

A similar situation can occur when air leaks appear or problems arise with the air flow sensor (MAF). In this case, the control unit incorrectly calculates the actual amount of air that enters the cylinders, as a result of which the correct ratio of fuel and air will be disrupted (disturbance of mixture formation).

Malfunctions of the carburetor and other systems

The second most popular system that fails in the VAZ-2107 is the carburetor.

- First of all, check the idle air valve and jets. The valve needs to be replaced and the jets cleaned. Buy only high quality components so that they do not break down quickly.

- The second common malfunction of the carburetor unit is air getting into it. The place where it is sucked in can be found by visually inspecting the hoses. Most often, the thin hose of the vacuum corrector loses its seal. Many technicians recommend simply replacing all the hoses, since air can enter the carburetor through microcracks.

After checking the fuel system and carburetor, you need to pay attention to the distributor. Be sure to check the quality of the ignition contacts that distribute the impulse to the spark plugs

If the contact burns out, the engine will “triple”, “double”, and jerking will be felt while driving.

If you do not find a malfunction here, then check the spark plug wires. Experts recommend changing them, like carburetor hoses, at the slightest suspicion. Usually the problem is hidden in insulation breakdowns, which may not be visible to the naked eye.

When inspecting and checking the wires, pay attention to the ignition coil and its wire

In the rarest cases, the car may move jerkily due to the spark plug failing soon. Typically, this behavior is unusual for this element of the ignition system, but car mechanics sometimes encounter this problem. The fact is that before failure, the spark plug begins to spark randomly, creating failures in ignition. The engine reacts to this with jerks and uneven running. Modern spark plugs most often do not behave this way; spark problems occur with inexpensive options with low quality.

Characters without spaces – 4468

Uniqueness of ETHT – 98%

Uniqueness of Text.ru – 100%

Academic nausea Advego–7.5%

Advego word frequency – 1.61%

There is a special offer on our website. You can get a free consultation with our corporate lawyer by simply submitting your question in the form below.

What's the result?

As you can see, at the initial stage of diagnosis, if the engine twitches at idle, you should start with the simplest:

- check spark plugs and high-voltage wires;

- assess the condition of the air and fuel filter;

- if the car has a carburetor, clean and adjust the carburetor;

- on the injector, check and wash the nozzles;

- perform computer diagnostics of the engine;

If the diesel engine jerks at idle, then problems with the injection pump should also be added to the general list of possible problems. The pump has many moving elements, damage to which or clogging can also lead to jerking or obvious tripping in the cylinders.

Why might the engine vibrate at idle? Causes of malfunction, diagnostics. Tips and recommendations for reducing engine vibration levels.

In idle mode and at low speeds, the engine shakes: possible reasons for the unstable operation of the power unit. Self-diagnosis methods.

For what reasons may misfire of the fuel-air mixture occur in one or more cylinders? Fault diagnosis, recommendations.

Signs of a non-working cylinder (tribbing and vibration) of a diesel engine. Troubleshooting: compression, diesel injectors, glow plugs, injection pump and others.

Causes of vibration and unstable operation of a diesel engine in idle mode. Possible causes and fault diagnosis.

Engine trouble: symptoms. Why does tripping occur and how to find the reason why the motor starts to trip. Checking power, ignition, compression, etc.

Situations when a car starts to jerk for no reason are common. In some cases the problem is resolved quickly, but in others it cannot be resolved for a long time.

The whole problem here lies in the reasons for this phenomenon, which are not so easy to identify as it seems at first glance.

But we will try to help you with this.

Let's try to figure out in detail what can cause the car to jerk while moving. But to do this, you first need to understand how everything happens.

Failure in the ignition system

If no problem is found in the fuel supply system, you should look for it further - in the ignition system.

The first thing you should always do is check that the distributor is working properly. The quality of contacts and those responsible for supplying high-voltage pulses to the spark plugs. If these contacts burn, the operation of the motor may be disrupted and an effect may occur when the engine triples or doubles. If everything is fine with the distributor, you need to check the condition of the high-voltage wires on the spark plugs. In the event of an insulation breakdown, they can have this effect.

Separately, it is worth diagnosing the ignition coil and its wires. In some cases, the problem may be located there.

In very rare cases, it happens that a spark plug, which can be said to be “on its last legs,” can produce a spark in a chaotic manner, which also negatively affects the operation of the engine.

For engines with an injector, the causes of malfunctions may be identical to those for carburetor engines. And eliminating these problems is done in the same way. In addition to possible malfunctions in the electronic components of the injector. Then you cannot do without accurate diagnostics of all electronics.

When the car jerks when braking, pressing or releasing the clutch pedal, this indicates possible wear or damage in these systems. These defects are eliminated through inspection and revision.

Quick diagnostics

So, the car is started, the speed is turned on, the clutch is slowly released, and the engine speed gradually increases.

But instead of smoothly starting from a stop and starting to pick up speed, the car begins to jerk - the speed fluctuates, the speed either increases or drops sharply, despite pressing the accelerator pedal.

This can continue until either the twitching goes away on its own and the car begins to confidently gain momentum, or until the engine stalls.

It happens that the car starts moving quite safely, but as soon as the revolutions increase to 2000-2500, uneven movement begins, accompanied by sharp changes in engine operation, as well as in the speed of movement.

conclusions

By checking these possible causes, your problem can be resolved in no time.

Remember that if you do not feel that you can cope with such work yourself, then be sure to contact a service station for professional help.

Recently, several not very pleasant symptoms have appeared on my Kalina, a list of which I have given below:

- The car began to jerk at low speeds. This was especially pronounced when shifting, if the speed was not too low for a particular gear

- Idle speed has become a little unstable, but the spread is small: from 800 to 880 rpm

- Fuel consumption has increased slightly. If earlier the instantaneous flow rate at idle was 0.8-0.9 l/hour at a temperature of 83 °C, now it has become 0.9-1 l/hour.

In general, I drove with this problem for about a month, and at first I thought that the quality of gasoline played a negative role. But after refueling at another gas station, everything was the same. Of course, all this was not particularly annoying, since the symptoms were barely noticeable, except that twitching in the lower parts sometimes bothered me.

In general, yesterday I finally decided to deal with this problem, and the first thing I decided to check was the throttle position sensor. It seemed to me that he was responsible for all the problems that arose. I have quite a few similar sensors in stock, so I decided to take the latest one from Kalina 11194. I installed it instead of mine, and now for the second day the problem has not appeared.

That is, everything became the same. The revs became more stable, the car stopped jerking, although I deliberately lowered the revs until the car practically refused to drive in a certain gear. As for fuel consumption at idle, it also returned to normal: 0.9-0.8 l/hour.

Many car enthusiasts have come across the concept of Lada Kalina twitching at low speeds. This malfunction can be associated with different car systems, but not every car owner is able to find this malfunction and fix it.

The video shows an example when an 8-valve engine operates “jerkily”, and what to do about it:

Car jerking at low speeds

Checking the engine power system.

Often the reason for the car twitching at low speeds is the power system, or rather, a malfunction in its operation.

When starting to move, the required amount of fuel simply does not enter the cylinders; the car is unable to produce the required power to evenly operate the transmission.

At the same time, transmission resistance leads to uneven running.

When jerking occurs at low speeds, first of all you should check all the elements related to the power system, and it makes no difference what kind of system it is - carburetor, injection or diesel.

It is recommended to immediately check the condition of all pipes. Depressurization of the system almost always leads to air being sucked in, which leads to fuel starvation of the engine.

And only after checking the condition of the pipelines can you proceed to the remaining elements of the system, which will be discussed below.

Also, the cause of jerking at low speeds can be the ignition system, especially for injection cars, where the entire operation of the system is controlled and regulated by an electronic unit.

A malfunction of one of the sensors can easily cause the machine to twitch.

At stable high speeds

But the jerking of the car at high speeds is more related to the ignition system.

In a normally operating engine, the ignition system automatically adjusts to certain conditions by changing the ignition timing.

That is, when necessary, the ignition becomes either a little early or late.

A malfunction in the automatic ignition will cause twitching.

Do not forget that the cause of uneven movement will be not only a malfunction of the system, but also the failure of one of its elements.

And these are only the reasons that can arise with the engine, without affecting the transmission.

We narrow down the search for reasons.

In general, you can immediately narrow your search for identifying the causes of car twitching to two engine systems - fuel and ignition, but you should not discount the transmission.

Is it due to the fuel filter?

So, it has been determined that the car jerks only under certain conditions. The fuel system pipes are all normal, but it is believed that the cause lies in the fuel system.

This means that the filters need to be checked next. Often it is because of them that this malfunction appears.

The task of any filter element in the fuel system is to clean the fuel from impurities, but at the same time, these impurities do not disappear anywhere, they remain in the filter itself.

Over time, it becomes so clogged with impurities and dirt that its throughput drops, and greatly.

As a result, the fuel pump pumps as expected, but the fuel does not have time to pass through the filter elements and the engine begins to “starve”, accompanied by the car jerking. There is only one way out here - .

If you take into account a carburetor car, then the number of filters it has is 2-3 pieces, but one of them, the usual mesh on the fuel receiver, can be practically discounted.

This mesh is aimed only at catching large particles, so it is practically incapable of becoming clogged to such an extent that it stops the flow of fuel in the required quantity.

But the second filter, usually located in the pipelines leading to the fuel pump, is worth checking.

This filter is designed to capture smaller particles, and it is not difficult for it to become clogged.

The third filter is not available on all carbureted vehicles and is usually located at the fuel inlet to the carburetor. It is also a regular mesh, but only fine.

This filter itself is small, so it often gets clogged.

Older machines had another filter installed - a coarse filter, also known as a sediment filter.

The design of this filter is such that it is not capable of becoming clogged to such an extent that it will not allow fuel to pass through. But this filter will subsequently cause rapid clogging of the fine filter.

If this filter accumulates a large amount of debris and dirt, then eventually it will not begin to clean the fuel from impurities, but, on the contrary, will begin to add them.

Injection car filters.

Most modern injection cars are also equipped with three filters. The first of them is a mesh for catching large particles installed in the neck of the tank. This mesh is clearly not the cause of the twitching.

The second filter is located on the fuel pump installed in the tank. This filter is also often a mesh, only with smaller cells; its task is to prevent large debris from entering the fuel pump.

It is also unlikely that it can cause a fuel shortage.

But the third filter, a fine filter, is located behind the fuel pump and is quite capable of becoming clogged to such an extent that the pump cannot push the required amount of fuel through it.

On more modern cars, there may be additional filters, which can also cause the car to twitch.

Lada Kalina twitches

Recently, several not very pleasant symptoms have appeared on my Kalina, a list of which I have given below:

- The car began to jerk at low speeds. This was especially pronounced when shifting, if the speed was not too low for a particular gear

- Idle speed has become a little unstable, but the spread is small: from 800 to 880 rpm

- Fuel consumption has increased slightly. If earlier the instantaneous flow rate at idle was 0.8-0.9 l/hour at a temperature of 83 °C, now it has become 0.9-1 l/hour.

In general, I drove with this problem for about a month, and at first I thought that the quality of gasoline played a negative role. But after refueling at another gas station, everything was the same. Of course, all this was not particularly annoying, since the symptoms were barely noticeable, except that twitching in the lower parts sometimes bothered me.

In general, yesterday I finally decided to deal with this problem, and the first thing I decided to check was the throttle position sensor. It seemed to me that he was responsible for all the problems that arose. I have quite a few similar sensors in stock, so I decided to take the latest one from Kalina 11194. I installed it instead of mine, and now for the second day the problem has not appeared.

That is, everything became the same. The revs became more stable, the car stopped jerking, although I deliberately lowered the revs until the car practically refused to drive in a certain gear. As for fuel consumption at idle, it also returned to normal: 0.9-0.8 l/hour.

It is worth noting that when the problem described above occurred, no ECM errors were detected. BC "State" did not see anything unusual in the behavior of my Kalina.

Jerks at low speeds and when starting off Lada Kalina

Many car enthusiasts have come across the concept of Lada Kalina twitching at low speeds. This malfunction can be associated with different car systems, but not every car owner is able to find this malfunction and fix it.

The video shows an example when an 8-valve engine operates “jerkily”, and what to do about it:

Causes of malfunction

General view of the engine

As in any car, in the Lada Kalina, jerking at low speeds is the first sign of a malfunction in one of the systems. Let's look at where the main problems arise:

- The fuel system and its components can cause the problem.

- The ignition system is associated with the fact that the car jerks at low speeds.

- Another reason could be the gearbox.

To more accurately determine the causes of the malfunction, it is worth considering each system and component separately.

Fuel system

The car jerks at low speeds - this may be due to the fact that the engine does not receive enough fuel mixture.

The problem may lie in the fuel system. In this case, you will have to examine several elements that are part of it.

Fuel rail and fuel injectors

Let's look at finding the problem step by step:

- The first place to look for a problem is the fuel rail and injectors. It is the poor condition of this unit that can cause the car to jerk when accelerating.

- The fuel pump, filter and lines can cause the driver to feel slight jolts at low speeds.

For diagnostics, you will need to remove the fuel pump from the gas tank housing. The mesh (strainer) in the fuel pump on a Lada Kalina is clogged - Poor fuel quality is one of the reasons for this effect.

You can diagnose these components and parts yourself or contact a car service center.

Ignition

The ignition system can cause the car to jerk at low speeds. Particular attention should be paid to the ignition switch, in which the contact connections may fail.

A red glow plug removed from the engine

The second reason could be the spark plugs. Their serviceability and contamination can lead to the fact that the car will not only twitch at low speeds, but also work unstably in other ranges. To prevent this from happening, it is necessary to choose spark plugs with the required gap and recommended by the manufacturer.

Transmission

The most unpleasant consequence of the effect may be the gearbox. In this case, you will have to remove the gearbox, change the oil in it and add new oil to the level. And also carry out a complete disassembly of it for diagnostics. Thus, the reasons may be failed synchronizers of 1st and 2nd gears, wear of gears or shafts. Another problem can be bearings that are worn out.

Gearbox disassembled

Of course, you should trust the diagnosis of this unit to professionals at a car service center, but if possible, you can try to fix the malfunction on your own. Ultimately, when all else fails, they will always be happy to see you at the car service center.

So, finding the reason for the Lada Kalina jerking at low speeds is quite difficult, because the problem may lie in the main systems, therefore, if the car enthusiast is not confident that he can find and fix the problem, then it is better to immediately contact a car service center.

Lada Kalina twitches at low speeds: reasons, repairs, photos

Car: Lada Kalina. Asks: Borisov Dmitry. The essence of the question: When starting off, the Lada Kalina twitches, why?

Hello, I have the following problem on my car: When I start driving, the car starts to jerk, sometimes I even feel small impacts. However, during a full trip I do not observe such a problem. I can’t even think what the reason is. Please tell me?

The main reasons for “twitching”

If similar symptoms occur on cars of the Lada Kalina family, there may be several reasons, and we bring them to your attention.

The following two tabs change content below.

Engine and gearbox mounting

This element is designed for the best shock absorption of the engine or gearbox while simultaneously fixing them to the body. It is very easy to check these elements for integrity. It is enough to check the play of all connections and make sure that there are no large cracks on its surface.

There is an old pillow on top and a new one on the bottom.

Please note that if there is engine play on one side, you will have to change it on the other.

If the engine and gearbox mounts completely fail, then in addition to the jerking of the car there will be a terrible grinding sound of metal on metal.

On the left is the new pillow, on the right is the old one.

Constant velocity joints (CV joints or “Grenade”)

The CV boot begins to “repair”. Perhaps dirt got in and the CV joint failed

As you know, there are two types of CV joints on Lada Kalina: internal and external. The internal one transmits rotation from the gearbox, and the external one supplies force to the wheel. Checking CV joints is quite simple; you need to hang each wheel in turn and check the play on each axle. If it is found, you can easily replace it with your own hands.

Clutch or flywheel

The photo shows the clutch flywheel. It is intact and without scuffs, but wear is starting to appear

Judging by the reviews on most forums of Lada Kalina car owners, when such symptoms occur, most often the clutch gradually fails, or rather the flywheel, release bearing, or clutch disc.

How to do the work of dismantling the clutch on a Lada Kalina with your own hands is written in this article. If the previous two reasons did not help you in any way, then take the issue of replacing the clutch with the greatest seriousness, as this can lead to the greatest malfunctions in the future.

conclusions

By checking these possible causes, your problem can be resolved in no time.

Remember that if you do not feel that you can cope with such work yourself, then be sure to contact a service station for professional help.

LADA KALINA: JERKS AND DIPS WHEN DRIVING. THE ENGINE DOES NOT DEVELOP FULL POWER

There are times when you seem to be driving normally and then your car starts to jerk when starting from a stop, or when you start to shift to a higher gear it starts to stall. Or if there are no jerks or dips, but your horse does not seem to develop full power. what to do then? How to diagnose and find the cause yourself. The table below will help with this.

The engine does not develop full power, the car does not have sufficient throttle response Jerks and dips when driving the car List of possible faults Diagnostics Elimination methods

| The air filter may be clogged | You need to open and inspect the air filter | Removing or blowing out the filter |

| Increased resistance to gas movement in the exhaust system | We inspect the exhaust system itself for bruises and damaged pipelines, check the condition of the catalytic manifold | We replace damaged elements of the exhaust gas system (the pipelines themselves) |

| possible leakage of foreign air into the intake tract | We inspect the joints, check the fit of the hoses, fittings, and the tightness of the clamps. Diagnostics - turn off the vacuum brake booster for a short time, plugging the receiver fitting. (Caution! The force on the brake pedal will increase significantly!) | We replace gaskets, parts with deformed flanges, and replace a faulty vacuum booster |

| Incomplete throttle opening | Determined visually with the engine stopped | Adjust the throttle valve actuator |

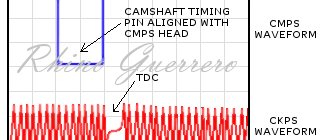

| Disturbed valve timing | Checking the alignment of the marks on the crankshaft and camshaft pulleys | We establish the correct relative position of the shafts (by marks) |

| Low compression in the engine cylinders (less than 11 bar): wear or damage to valves, their guides and seats, stuck or broken piston rings | Checking the compression | We replace faulty parts |

| The gaps between the electrodes of the spark plugs do not correspond to the norm | Check clearances | Bend the side electrode, set the required gap or replace the spark plugs |

| Heavy carbon deposits on the spark plug electrodes; ingress of carbon particles into the gap between the electrodes | Diagnosed only by examination | Check or replace spark plugs if necessary |

| The insulation of high-voltage devices and circuits is damaged | Using an ohmmeter, check for open or breakdown (short to ground) of the ignition coil windings and high-voltage wires | We replace a damaged ignition coil and high-voltage wires |

| There is not enough fuel in the tank | By level indicator and fuel reserve indicator | Add fuel |

| The fuel filter is clogged, the water that has entered the power system is frozen, the fuel lines are deformed | Check the pressure in the fuel system (at least 3.6 bar) | Replace the fuel filter. In winter, place the car in a warm garage and blow out the fuel lines. Replace defective hoses and tubes |

| The fuel pump does not create the required pressure in the system | Check the pressure in the fuel rail, make sure the fuel module strainer is clean | Clean the fuel module strainer. If we find something, then we replace the faulty fuel pump, pressure regulator |

| Poor contact in the fuel pump power circuit (including ground wires) or its relay is faulty | Checked with an ohmmeter | Clean the contacts, crimp the wire ends, replace the faulty relay, wires |

| Faulty injectors or their circuits | The Check indicator is on. Check the injector windings and their circuits with an ohmmeter (no open or short circuit) | Replace faulty injectors, ensure contact in electrical circuits |

| Crankshaft position sensor not installed correctly | Check the gap between the sensor and the teeth of the crankshaft drive disk (0.5-1.5 mm) | Clean the sensor rod of any metal particles. Replace damaged sensor |

| The phase sensor or its circuits are faulty | The Check indicator is on. Check the sensor with a tester | Restore contact in the electrical circuits, replace the faulty phase sensor |

| The mass air flow sensor or its circuits are faulty | You can evaluate the performance of the mass air flow sensor using diagnostic equipment at a service station | Restore contact in electrical circuits, replace the faulty sensor |

| One or both oxygen concentration sensors are faulty | The Check indicator is on. You can evaluate the performance of oxygen concentration sensors and the reliability of the connections of their electrical circuits using diagnostic equipment at a service station | Restore damaged electrical circuits Replace faulty sensor |

| The controller or its circuits are faulty | The Check indicator may light up. To test the controller, replace it with a known good one. | Replace the faulty controller |

| The clearances in the valve drive are not adjusted | Check valve clearances | Adjust the clearances in the valve drive |

| Severe wear on the camshaft cams | Inspection after partial disassembly of the engine | Replace worn camshaft |

| Loose or broken valve springs | Inspection during engine disassembly | Repair the engine |

| The throttle position sensor or its circuit is faulty | The Check indicator is on. Check the throttle position sensor | Restore contact in electrical circuits, replace the faulty sensor |

| The coolant temperature sensor (engine management system) or its circuit is faulty | Check the sensor resistance at different temperatures with a tester | Restore contact in electrical circuits, replace the faulty sensor |

Why does the car jerk while driving? Reasons for car jerking while driving

Malfunctions and disturbances in engine operation can manifest themselves in different ways, starting with suspicious sounds coming from under the hood, leaks that remain on the asphalt after a long stay, ending with jerks while driving.

Jerking while the car is moving can occur no matter how much you press the gas pedal; this occurs as a result of a short-term change in the speed of rotation of the crankshaft. Dips can occur not only during acceleration, but also when releasing the gas, as well as with constant movement and the same position of the gas pedal. In order to understand why the car jerks when driving, it is best and easiest to contact specialists at a service station, because, most likely, you will have to carry out a complete diagnosis of the fuel system and injection system, and for this, as you understand, you need to have special equipment . In most cases, jerking while driving occurs due to a lack of pressure in the fuel rail, or as a result of a malfunction of the throttle position sensor (TPS).

The car jerks while driving - reasons

Sometimes when you start moving, when you start moving, a “failure” occurs, and often for beginners this can even cause the engine to stall. This effect occurs precisely at the moment when the throttle valve opens, when the engine goes from idle to load mode. In modern engines, the motor helps the driver, for smoothness the ECU, having received a signal from the TPS about the throttle position, will increase the fuel supply. However, if the pressure in the fuel rail is weak, there will still not be enough fuel.

The reason for jerking while driving may also lie in the electromechanical part of the throttle valve or in its banal contamination by crankcase gases. The cause of such contamination can also often be caused by insufficient pressure in the fuel rail. When you sharply press the gas pedal in order to instantly accelerate, the throttle valve opens very wide, while the ECU, having received a signal from the TPS about the throttle position, without having the required pressure, is simply not able to provide the engine with the required amount of fuel.

In cars with automatic transmission, the car jerks when accelerating due to a faulty gearbox or, for example, because the oil level in it is too low. Sometimes “jokes” with the gearbox can occur after disconnecting the battery immediately before a trip; this phenomenon is “not fatal” and, as practice shows, goes away by itself after several accelerations.

Often the reasons are completely banal, for example: the fine fuel filter is clogged, the fuel pump mesh is clogged, etc. But I think that you, like most of us, checked this first, and if not, then by all means do it.

The car jerks while driving - reasons

As a rule, such jerks occur due to a malfunction of the ignition system. However, if a problem occurs on the road, you can try to fix the problem yourself. To do this we do the following:

- Turn off the ignition, lift the hood and make sure that all high-voltage wires are securely attached to the coil and spark plugs.

- Then start the engine and listen to the engine, listen for any extraneous crackling or clicking noises. The point is to check whether there are any “breakdowns to ground”, that is, whether the spark is going somewhere else other than the spark plug. This is best checked in the dark, then you will not only hear a crash, but also see how it hits, for example, on the body or somewhere else.

If the check does not lead to anything, I recommend unscrewing the spark plugs and inspecting them; perhaps there is carbon on the spark plugs or they simply need to be replaced. If you have a set of new spark plugs, check to see if the engine's performance changes or if the jerking goes away after replacing the spark plugs. If the car jerks at speed even after replacing the spark plugs have disappeared, then the problem was in them, but if not, continue searching or try to reach the nearest service center, they will certainly help you solve your problem.

The car jerks in first gear or second speed: fault diagnosis

As mentioned above, in such a situation, the first step is to gradually eliminate problems in the power supply system, ignition, as well as failures in the ECM. For example, a common reason when the car jerks at low speeds when engaging first and/or second gear is insufficient fuel/air supply to the engine or impaired mixture formation.

The result is that the engine is unstable, the unit in different modes does not have enough power to “turn” the box, which leads to noticeable jerks in movement. The culprit of the problem may be air leaks, contamination of the injection nozzles or fuel pump mesh, or problems with the carburetor.

Various ECM sensors (Hall sensor, TPS, mass air flow sensor, etc.) can also malfunction. If everything is fine with the sensors, then you need to check the engine ECU. Quite often, the problem of jerking in 1st-2nd gear is directly related to the ignition. It is necessary to check the condition of the spark plugs and high-voltage wires, distributor and other elements on a particular machine.

As a rule, if the car drives jerkily, in relation to injection cars, specialists conduct comprehensive computer diagnostics of the engine. If such a check does not produce results or the cause is not found, then the vehicle’s transmission deserves special attention.

- So, if your car is noticeably jerky in 1st and/or 2nd gear, it is important to understand that the transmission may also be causing the car to jerk when driving. At the same time, it is easier to determine the cause in the case of a manual transmission, while various types of automatic transmissions require more serious checks.

Let's start with the manual transmission. Please note that if an inexperienced driver's car jerks in first gear when starting off, it should be taken into account that often beginners simply make mistakes when releasing the clutch, while the car itself is working properly.

To start without jerking, you need to smoothly release the clutch before the driver feels the grip point (the beginning of the transmission of torque from the engine to the wheels). After the force begins to be transmitted to the wheels and the car begins to move, you need to carefully add gas, dosing the traction with the pedal accelerator.

If an experienced driver is driving, then he can quickly identify the problem. So, on cars with manual transmissions, the gearbox itself often has nothing to do with the problem of jerking in gears when driving. In other words, in cases of gearbox failure, other problems are noted when the gears may not engage, grinding, humming, vibration of the gearbox, etc. appear.

But jerking is usually caused by problems with the clutch on the manual transmission or its adjustments. For example, a car jerks in first and second when the clutch driven disc is badly worn, the clutch does not “close” completely, and slips. This leads to the car jerking when changing gears.

In this case, jerks most often appear precisely in “low” gears (first, second speed), when the smoothest possible operation of the clutch is needed and at the same time, through the clutch in these gears, a sufficiently large torque is transmitted from the internal combustion engine to the gearbox when accelerating the car.

- Now let's move on to automatic transmissions. First of all, you need to take into account that the quality of operation and smoothness of automatic transmission shifts will depend on the type of automatic transmission.

First of all, jerking can occur when driving with robotic gearboxes that have both one and two clutches. The fact is that the clutch of such gearboxes resembles in its design and principle of operation a conventional friction clutch of a manual transmission. Often the solution to the problem is to replace the DSG or AMT clutch, after which it is imperative to adapt the clutch (training, setting the grip point).

We also recommend reading the article about why there is a crunching noise in the gearbox. From this article you will learn about the reasons for its occurrence, as well as how to repair the gearbox.

Also, in some cases, the culprit that the car jerks when driving in 1-2 gears may be breakdowns and malfunctions in the actuators that are responsible for the operation of the clutch in automated mode.

As for CVT variators and hydromechanical automatic transmissions, in this case, when jerking occurs, in-depth diagnostics are required. The fact is that such gearboxes do not have a traditional clutch. In this case, the automatic transmission clutch is a separate device (torque converter), where torque is transmitted through transmission oil. In this case, the gas turbine engine may well fail, which becomes the cause of jerking.

It should also be noted that the automatic transmission itself can “slip”, and the quality of its operation greatly depends on the level/condition of the transmission oil (ATF fluid). Jerking in automatic transmissions of this type may occur due to insufficient or overfilled oil, the use of a lubricant with unsuitable properties, etc.

Jerking in a car with an automatic transmission in certain gears (especially during shifts) may indicate problems with the brake band, valve body, automatic transmission solenoids, sensors, separate automatic transmission ECU, etc. Taking into account the above, we can conclude that the machine needs to be checked comprehensively, paying special attention to the level of lubrication and the quality of the oil itself.

What's the result?

As you can see, if a car jerks in first gear or a car jerks in second gear, there can be quite a few reasons. If we talk about the transmission, often with manual transmissions and many types of robotic gearboxes, a common cause is a worn clutch (both as a whole and individual elements) or malfunctions in the actuators responsible for the operation of the clutch on a manual transmission.

We also recommend reading the article about what a manual transmission additive is. From this article you will learn about the purpose and features of various additives for manual transmissions, as well as when to optimally use them. In the case of hydromechanical automatic transmissions, diagnostics are greatly complicated by a large number of sensors and the presence of a torque converter, which is a separate element. For this reason, it is recommended to carry out comprehensive computer diagnostics of the automatic transmission, as well as perform a number of tests and checks, which are carried out by experienced automatic transmission repair specialists at specialized service stations.

Finally, we note that if the owner notices that the car begins to jerk in first gear, the car jerks in second speed, etc., it is better not to delay in determining the cause. On the one hand, quick troubleshooting will allow you to avoid more serious problems and costly breakdowns, but on the other hand, jerking and jerking in the first and second gears can cause accidents and other troubles on the road.

eurasia-today.ru

Other elements of the fuel system

Now on to other elements of the fuel system.

The next culprit for uneven running may be the fuel pump.

In carburetor cars.

A mechanically driven diaphragm fuel pump is often used here.

So, even a small rupture of the membrane will cause the pump’s performance to drop sharply.

The pump valves may also be to blame. They can easily break the sealing of the device’s chambers, which leads to a drop in fuel supply.

The fuel pump can also cause jerking. On such cars, since the pump is located in the tank, it is electrically driven.

A decrease in device performance leads to the problem described in this article. Here you need to consider a specific case separately.

Now directly about the carburetor.

Because of this, uneven running of the car is also possible. Often such a malfunction occurs due to severe clogging. Debris and dirt can block channels, forget jets, etc.

Sometimes the reason lies in the accelerator pump. A diaphragm accelerator pump is installed on carburetors, the task of which is to increase the fuel supply when the gas pedal is sharply pressed.

But if the membrane is torn, then the accelerator pump will not be able to increase the supply of gasoline, and hence fuel starvation.

For injectors, the fuel injectors are checked next. Violation of their performance leads to jerking of the car.

Injectors need to be cleaned periodically, in principle, like everything else.

Also, in an injection car, the functionality of all sensors involved in the operation of the power system is checked, and then the electronic control unit is checked.

Thank you Dislike SHARMAX Oct 28, 2010

So, the continuation of my story: I finally found the time and, together with a smart person, took care of the car, namely, they changed the gasket between the head and the block, after which they started starting it - the car would not start. We removed the cover again and put the chain on the sprocket more precisely, the marks coincided. They started starting it, but it wouldn’t start again. We noticed that they had installed the distributor incorrectly (not on the 1st cylinder, but on the 4th). They started to start it - it started to catch, but just a little bit was missing for the engine to start on its own. They turned it for a long, long time (the engine even got hot), almost in despair, they turned it up and the car started up. BUT there are strong pops in the carb and in the exhaust pipe (in turn, as it were), without gas supply the car stalls. The ignition and carburetor did not have time to be set correctly (night had fallen). Why are there claps, I don’t understand what options there may be, comrades?

It looks like the distributor was installed incorrectly (no matter what!)! And how are things with compression? Are the valves pinched? Regarding the distributor. When installing it, you should keep in mind that 1 camshaft revolution = 2 crankshaft revolutions, therefore, with the same position of the mark on the RV sprocket, the distributor can occupy 2 different positions! If you are sure that the distributor is installed correctly (with this position of the mark, its slider points to the explosive wire of cylinder 1), first try changing the position of the distributor by 180 degrees. If it doesn’t help, we check the compression and draw a conclusion about the condition of the valves (often after assembling the engine they are simply pinched; I’ve been burned by this myself more than once). If this doesn't help, write again, we'll come up with something else.

About the transmission

Now a few words about the transmission, since it can also cause jerks when driving.

As you know, cars use manual and automatic transmissions.

As for a manual transmission, the gearbox and everything that follows it cannot cause jerking.

A manual transmission is a fairly simple design, and if it already breaks, it breaks specifically, and not creating jerks.

But the clutch can cause jerking. If it is heavily worn, in particular the driven disk, or “slips,” then the car easily begins to twitch.

But as a rule, jerking and twitching with such malfunctions occurs during gear shifting.

But in automatic transmissions, the cause of the twitching is precisely the gearbox itself.

It is very dependent on the quantity and quality of oil, so a lack of oil or its foaming can easily cause uneven running of the car.

You can measure the oil level in the automatic transmission using a dipstick.

It all depends on the design of the automatic transmission.

Significant wear of the automatic transmission, as well as clogged oil channels, also causes the car to jerk at all speeds.

Thank you DislikeLeksik Oct 19, 2010

In general, by the way, you may be right, because: when I drove in the summer, this tube (crankcase ventilation) was disconnected from the pan and was hanging stupidly, then I attached it in the fall. Then some strange white liquid appeared, accumulating on the engine cover and through the tube fell into the pan. They told me that some water got into the engine. And they told me to just change the oil (haven't done that yet). After the white liquid appeared, the tube was again pulled off the pan. So I think she probably has nothing to do with it. But is carbon deposits on the candles due to the evaporation of some kind of rubbish possible? As a result, engine interruptions occur.

In fact, a white emulsion is a sign that coolant (antifreeze, antifreeze) gets into the oil, the water would simply evaporate without consequences... But why it gets there is the question... most often it happens from the head gasket... If you have done this recently capital, then perhaps the head was not pulled through properly... well, or the gasket turned out to be defective...

Checking VAZ-2107

Now let's take a closer look at how to identify the cause of such a malfunction on different car models.

The first will be the carburetor VAZ-2107; there are plenty of cases when the car suddenly starts to jerk while driving.

As already mentioned, you need to start checking with the fuel system:

- First you need to inspect all pipes of the system for cracks;

- Open the tank. It happens that in the summer the lid fits very tightly to the neck, blocking the access of air to the tank. When moving, the pump works and creates a vacuum in the tank, due to which the same pump is then unable to “pull” fuel. It seems like a small thing, but this also happens;

- Inspect the fuel filter located in the pipes leading to the fuel pump. These filters are transparent and easy to visually evaluate;

- You can also check the fuel pump without removing it. It is necessary to disconnect the pipeline coming from the pump from the carburetor and lower its end into some container. Then manually pump the pump into action and evaluate how it pumps fuel - it should supply it in even portions;

- While the fuel pipe is disconnected from the carburetor, unscrew the fitting on which the fuel line fits and remove the small mesh filter, clean it and reinstall it;

- Next comes the carburetor. It is advisable to remove it from the car, rinse it thoroughly, and inspect the accelerator pump membrane.

- We unscrew the spark plugs, check their functionality, and replace them if necessary;

- We check the system wiring for breakdown. This can be done this way - in the dark or in a closed garage (the main thing is that it is dark), open the hood and start the engine. If there are voltage losses on the wiring, they will be immediately noticeable by the sparks that form. Next, we replace the wiring that “breaks through” and check the wire connections;

- Next, we check the distributor, there should be no signs of critical wear, it should be dry under the cover. Be sure to inspect the centrifugal regulator, and also check the vacuum regulator. You should check whether there is a vacuum in the pipe leading to it.

- Then the Hall sensor, coil and switch will be checked for functionality. You can do this yourself if you have the necessary equipment at hand, but you need to know how to check them. But you can contact an auto electrician.

- It is also important not to forget to check the correctness.

If actions with the fuel system did not help, we proceed to checking the ignition system.

This is in general and all the features of identifying the cause of uneven running on the VAZ-2107.

5.1.6 The car moves jerkily

— jerk

— a short-term spontaneous change in engine speed, regardless of the position of the gas pedal.

In everyday use, as a rule, there are a series of jerks; — failure

— a noticeable delay in the engine’s response to pressing the gas pedal. Approximately can be considered as a limiting case of a jerk.

Conventionally, three types of jerks can be distinguished:

- at the moment of starting movement; — during acceleration; — with steady motion, i.e. with the gas pedal in constant position.

When using the DAAZ Solex carburetor, a very unpleasant defect occurs: when you press the gas pedal, a strong dip occurs, the engine stalls, and often there is no idle speed. Movement is only possible when the gas pedal is pressed to the floor, or you have to continuously “pump” the pedal. The reason is clogging of the fuel nozzle of the main metering system of the first chamber.

For an experienced car enthusiast

it is necessary to remove the top cover of the carburetor, as described above, unscrew the two air jets, use a thin screwdriver to unscrew the two fuel jets and remove them from the wells with a long wooden toothpick or a pointed stick.

Do not mix up the jets when reinstalling them!

Then, use a syringe or a clean, lint-free cloth to remove gasoline from the float chamber and blow out the carburetor with compressed air, especially carefully - the fuel nozzle wells.

For an inexperienced car enthusiast

It is better to immediately contact a car service center. To get to the service center, cut off a piece of vinyl chloride tube 1–1.5 cm long (at least from the windshield washer tubes) and place it on the thrust lever of the second chamber drive. The engine speed will be approximately 2000 rpm. Use the clutch and brake pedals to maintain a safe speed.

Jerking when starting to move

At the moment the movement begins, the limiting case of a jerk—failure—occurs more often. The most unpleasant sensations are associated precisely with the delay in the engine’s response to pressing the gas pedal. Sometimes the engine even stalls.

The cause of failure may be either a malfunction of the carburetor accelerator pump or a malfunction of the vacuum corrector of the ignition distributor.

For work you need: wrenches “8” and “10”, Phillips and slotted screwdrivers, a clean rag, a piece of thin copper wire without insulation with a diameter of less than 0.3 mm, a compressor, a can of WD40 type liquid, possibly a portable lamp.

| EXECUTION ORDER 1. Remove the air filter housing cover by unscrewing the nut with a “10” wrench and unfastening the spring clips. Remove the air filter. Unscrew the four nuts with a key “8”, use a screwdriver to loosen the clamp of the crankcase ventilation hose at the connection point to the valve cover and remove the air filter housing. 2. Disconnect the vacuum corrector drive hose for the ignition distributor and, creating a vacuum with your mouth, check for leaks. Does air flow freely? No: see point 4 3. Contact a car service to replace the vacuum corrector of the ignition distributor. 4. Look inside the carburetor. The air damper must be fully open. Press down on the throttle lever. Streams of fuel should appear from both accelerator pump nozzle tubes. The streams should be even and directed into the gap between the diffuser wall and the opening damper. If necessary, use a portable lamp. Is the fuel spray direction correct? No: see point 6 5. Contact a car service for diagnostics. 6. Avoiding fuel spillage, remove the fuel supply hose to the carburetor and the fuel drain hose. Remove the choke control cable and wire from the idle air solenoid valve. Remove the five screws securing the carburetor top cover. Remove the carburetor cover, carefully turn it over (the fastening screws will fall out - do not lose them!) and place it with the floats up. Do not damage the floats! 7. Using a screwdriver, carefully pry it as close as possible to the sealing point of the accelerator pump nozzle tube and, pressing upward, remove the nozzle from the socket. 8. Clean both holes of the spray nozzle with a thin copper wire. Blow air into the nozzle in the direction opposite to the direction of fuel flow. 9. Insert the sprayer into place. Without installing the carburetor cap, press the throttle lever. Streams of fuel should appear from both accelerator pump nozzle tubes. No: see point 11 10. Reassemble the carburetor and keep in mind that it is time to carry out maintenance, replace the fine fuel filter or change the gas station. 11. Check that the accelerator pump drive lever moves easily and that there is no play in the drive. If necessary, lubricate the parts with WD40 type fluid, replace faulty parts. Check the operation of the accelerator pump again. No: see point 13 12. Reassemble the carburetor and keep in mind that it is time to service it. 13. Contact a car service for diagnostics and repairs. |

Jerks during acceleration

The cause of jerking may be a low fuel level or a clogged fuel filter in the carburetor, a malfunction of the fuel pump or a clogged additional fuel filter, or a malfunction of the ignition system.

For work you need: wrenches “8”, “10” and “13”, Phillips and slotted screwdrivers, a clean rag, a piece of thin copper wire without insulation with a diameter of less than 0.3 mm, a compressor, a can of WD40 type liquid, possibly - portable lamp.

| EXECUTION ORDER 1. Remove the air filter housing cover by unscrewing the nut with a “10” wrench and unfastening the spring clips. Remove the air filter. Unscrew the four nuts with a key “8”, use a screwdriver to loosen the clamp of the crankcase ventilation hose at the connection point to the valve cover and remove the air filter housing. 2. Avoiding fuel spillage, remove the fuel supply hose to the carburetor and the fuel drain hose. Remove the choke control cable and wire from the idle air solenoid valve. Remove the five screws securing the carburetor top cover. Remove the carburetor cover, carefully turn it over (the fastening screws will fall out - do not lose them!) and place the cover with the floats facing up. Do not damage the floats! Look inside the carburetor. The gasoline level should be approximately 22–23 mm below the connector of the carburetor cover and body. Yes: see point 4 3. Adjust the fuel level by bending the float. To do this, gently press the float bracket with your thumb where it touches the carburetor needle valve. The gap between the cover gasket and the floats should be 1.5–2 mm. If the fuel level is high (the gap between the cover gasket and the floats is less than 1 mm), use a screwdriver to bend the tongue of the float bracket and increase the gap. 4. Using a key set to “13”, unscrew the carburetor fuel filter plug. Remove the plug along with the mesh filter and remove the filter. Don't lose the copper O-ring! Inspect the filter carefully. Do you have doubts about the cleanliness of the filter? No: see point 6 5. If in any doubt, rinse the filter with gasoline and blow with compressed air from the inside and outside. It is better to replace a heavily soiled filter. 6. Check the auxiliary fuel filter. Do you have doubts about the cleanliness of the filter? No: see point 8 7. If there is the slightest doubt, it is better to replace a dirty filter. 8. Reassemble the carburetor in reverse order and take it for a test drive. Yes: see point 11 10. Bon Voyage! 11. Fuel pump malfunction - fuel pressure is too low, or the ignition system is faulty. |

Jerks during steady motion

| GENERAL INFORMATION |

Such jerks are most often caused by a malfunction of the ignition system. Diagnostics required, contact a service center

. The only thing you can try to do yourself:

— carefully inspect the engine compartment. Turn off the ignition and check the secure fastening and seating of all wires and connectors at the switch, coil and ignition distributor. Start the engine and listen to its operation - the crackling sound when the high voltage breaks down to ground is weak, but distinct. In complete darkness, the spark during breakdown is clearly visible; — replace spark plugs regardless of their condition and mileage. Pay attention to the condition of the spark plugs - if it is abnormal, you may have to contact a car service

.

Checking VAZ-2110

Let's move on to a more modern car - the injection VAZ-2110, which can also twitch when driving.

It is also worth starting the check from the power system, but it is carried out somewhat differently than on the “Seven”:

- You need to start with the fuel filter and pump. The filter there is non-separable and diagnostics are done by checking the performance of the pump. It is impossible to carry out the work at home; it is better to contact a service station. There, a special device is connected to the outlet of the fuel filter to measure the outlet pressure. If the pressure does not correspond to the norm, then another measurement is taken, but the device is connected to the fuel pump before entering the filter. This way it is determined whether the insufficient fuel supply is to blame - the filter or the pump;

- Then the functionality of the injectors is checked. If everything is in order with the specified elements, then the check of the electronic component begins;

- First, all sensors are checked for serviceability and functionality; if they are serviceable, then all that remains is to check the control unit;

- The control unit can often cause jerking if its firmware is broken, that is, it does not operate in the mode it should.

Usually such a malfunction is “cured” by “reflashing”, but if there is internal damage in it, then it is replaced.

As for checking the ignition system, it is in many ways similar to checking the VAZ-2107 system.

It all starts with the spark plugs, then the wiring is checked, then all the components, but taking into account the fact that this system is controlled by an electronic unit that controls the operation of the engine using sensors.

So, when checking the ignition, you will also have to check the performance of the sensors and the unit itself.

How to find out the causes of the malfunction

- You will need two wrenches - "eight" and "ten", straight and Phillips screwdrivers, a clean rag, some copper wire. The wire diameter should be thinner than 0.3 mm.

- In addition, you will need a compressor and WD40 fluid.

The operating procedure is as follows:

- Armed with a ten key, remove the cover from the air filter housing by unfastening the spring fasteners. Remove the filter. Using an eight wrench, unscrew the nuts and you can now loosen the clamp on the crankcase ventilation hose where it connects to the valve cover. After this, you can remove the filter housing.

- Now you need to remove the vacuum corrector drive hose and create a vacuum to make sure it is tight.

- The corrector may need to be replaced. It’s better to entrust this to the car service workers.

- If air cannot flow freely during purging, then look at how things are going with the carburetor. For example, make sure its air damper is open. When you press the throttle lever, a stream of gasoline should come out of the nozzle. Make sure they are there and the fuel spray direction is correct.

- In case of any problems, the car must be sent for service.

- Carefully remove the hose leading the fuel to the carburetor, without spilling gasoline. We do the same with the choke control cable, and then with the wire that is located on the idle air solenoid valve. Now unscrew the screws securing the top carburetor cover. After removing the lid, place it with the floats facing up so as not to damage it.

- Now, using a screwdriver, carefully pry up the nozzle tubes and pull it out of the socket.

- After you do this, you need to take a thin copper wire and carefully clean the holes in the spray nozzle. Then you should blow it in the opposite direction (against the movement of fuel).

- We install the sprayer. In this case, without closing the carburetor cover, you need to press the damper drive lever. We check the appearance of streams of fuel running from the nozzle tubes.

- We assemble the carburetor.

- If there were no streams, then you need to check how easily the accelerator pump drive lever moves. We also check whether there is any play in the drive. If necessary, we lubricate it with WD40 and replace everything that is faulty.

- Let's check the streams again. If they are, we assemble the carburetor. If not, we go to the service center.

If the VAZ 2109 carburetor jerks during acceleration

Here the list of possible reasons is also extensive. This is both a malfunction of the fuel filter and the possibility of a low fuel level. It is also possible that the fuel pump is not working correctly, or the additional fuel filter is clogged. It could also be an ignition problem. It’s better not to delay and seek professional diagnostics.

You can also read on this topic:

Tuning Renault Sandero and some modifications on your own

The car exhaust system allows you to get rid of exhaust gases

High fuel consumption of VAZ 2109 (carburetor), what to do?

The instrument panel of the VAZ 2114 looks great and hardly breaks

Tuning VAZ 2111 - elegance and comfort of the car

Alex S January 8th, 2014

Published in: Useful tips and car devices

Tags: Advice for motorists