A faulty shock absorber strut can be determined without removal: indirect signs and visual inspection are sufficient. It is important to carry out replacement and repairs in a timely manner. Since the safety of the driver, passengers and other road users depends on the proper operation of the part.

There are as many as 4 different methods for checking the strut without removing it:

- careful inspection; for this purpose it is advisable to remove the wheel,

- monitoring work under load,

- monitoring the car in motion on turns, when driving over bumps,

- measurement.

Visual inspection

The first thing you need to pay attention to is the appearance of the rack itself. Sometimes it will tell you much more about its condition than other testing methods. If the stand is leaking or is wet, it is advisable to replace it. To be sure of the diagnosis, you can simply wipe the surface of the shock absorber with a dry cloth. Then repeat the inspection a few days later.

It is advisable to lift the car on a lift: the shock absorber rods should shine. If there are traces of rust or other defects, this indicates that the part is not working properly. Another indirect sign is the presence of defects on the car tires. The presence of uneven wear indicates an asymmetrical load. Among other things, it is important to assess the condition:

- protective kit - boots, springs,

- upper supports.

Load on the car body

The old, old-fashioned method is to rock the car body and see how the racks work out this movement. If after one shock the shock absorber has made more than 1 translational movement, then it is time to change it. But you need to remember: this method will only be relevant if the shock absorber is completely “dead”. It will also allow you to identify a jammed shock absorber. It will be simply impossible to rock the body.

Management, operation

Indirect signs of faulty shock absorber struts - problems when operating the machine:

- the wheels “yaw” when driving over uneven surfaces,

- there is a swing in different directions - for no apparent reason,

- lack of normal feedback on the steering wheel.

It must be remembered: such signs of faulty struts are present not only at high speeds. But even if the speedometer is much less than 60 km/h. It is important to remember that deterioration in controllability is one of the first signs of a malfunction not only in the steering system. But also shock absorbers.

Shock absorber knocking in winter

Reliable operation of the shock absorber in severe frosts is structurally built into it, especially in our domestic models.

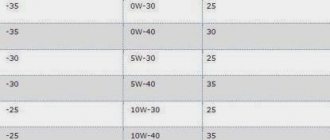

But it all depends on the type of oil that is used in it. Some shock absorber manufacturers are guilty of this and do not use all-season oil, but summer oil, which freezes in severe frosts, which is why the shock absorber begins to knock.

For example, we drove a car from a warm country to the north of Russia. Situations are different and a shock absorber operating in one weather conditions may behave completely differently in a different climate.

In this situation, the oil in the shock absorber should be replaced with non-freezing oil, then the knocking should stop.

Measuring distances and sizes

One of the simplest and most accurate ways to determine the presence of a malfunction is to measure the gaps and dimensions. The optimal solution: take it to a service station. Qualified technicians will definitely help determine whether replacement is necessary. It must be remembered that even one faulty shock absorber affects the efficiency of the vehicle’s suspension system.

It must be remembered that working with a stand in a workshop implies the need to configure it for a specific car. For example, it often happens that the data indicated almost complete wear of the car’s suspension. At the same time, on the road, regardless of speed, the car behaved perfectly. The reason was simple: the stand was simply not configured to work with a rigid suspension.

The engine knocks... there's so much in that sound!

Our super series “The Life and Death of the Iron Friend” continues. We dedicate the 9th issue to the sounds of a moving car. No, not the songs of Alsou or DeTsla from the speakers, but the sounds that are always the first signals of malfunctions in your car. Yuri GEIKO, presenter of "Avtolikbez".E-mail Necessary preface I experienced the shock of car sound for the first time in my life in the summer of 1968 when the AZLK team was traveling to the USSR Rally Championship in Yerevan. Eight cars, driven by the highest professionals, national champions, international masters of sports, all stopped at once if only one stopped. In the evening, 1,800 kilometers from Moscow, one driver stopped, got out and said to the second: “If you sit on mine, I don’t understand: when you get out of a hundred, it looks like the box is squealing.” They swapped steering wheels and after about forty kilometers they animatedly exchanged impressions about cars. Yes, changing steering wheels is always very useful, because after this you feel more keenly the disadvantages or advantages of your own car! Wheels When considering the unpleasant sounds of wheels, we will, of course, keep in mind the front wheels, because the sounds of the rear wheels, as a rule, are almost inaudible to the driver, and they are not so alarming. There are several “defective” sounds of the front wheels, let’s start with the most dangerous: - The knock of a loose wheel. To be honest, in more than thirty years of driving life I have not heard this sound - until last winter. And in February, Komsomolskaya Pravda was invited to a meeting with readers of the Yaroslavl region. In my top ten, my favorite Vasily Mikhailovich Peskov was sitting in front on the right. We walked in a column and didn’t want to stop. Somewhere at a speed of 130, when I let off the gas, the knocking sound is weak and disappears, so far only I can hear it. About ten minutes later, Vasily Mikhailovich became worried. I stop, look at the left wheel - everything is in place, we move on. Again there was a knock, this time stronger, and Vasily Mikhailovich seemed to just remember: one day he came out of the forest onto the road and saw how a wheel bounced off a car and how it rolled by itself! I think: is the wheel really not screwed in? I shook the steering wheel left and right and there was a knock. I give gas and it goes away. I stop again, take the wheel key - dear mother! Each wheel fastening bolt has already been unscrewed by three turns! Another ten minutes of driving, and... It’s a shame, of course, and Vasily Mikhailovich on the side of the road comments: “You know, I couldn’t speak to such a master as you, Yura, to say: maybe the wheel is not screwed in?” In general, the lesson was serious for me. The second sound - “boo-boo-boo” with a slight beating of the steering wheel - is the most common on our roads - a bump, hernia, swelling of the bead due to a torn tire cord. It is easy to see if you spin the jacked wheel. With such a defect, the wheel is only suitable for use as a spare tire. The "eight" tire makes almost no sound, but the beating of the steering wheel and the car is clearly expressed. You can ride, but it’s uncomfortable. A knock (crunch) only when turning - either the hub bearing (with rear-wheel drive) or the CV joint (with front-wheel drive) is faulty. Hang the wheel up and swing it back and forth by the sides. If there is play and knocking, the bearing is to blame. It urgently needs to be repaired, it may jam. The last sound is a squeak both when turning and on a straight line, on potholes - as a rule, the decorative linings of the disks are to blame. Try driving without them. Wheel knocks are knocks from shock absorbers, ball joints and tie rod ends. The knock of the shock absorber corresponds to each pothole, the ball ones knock when crossing the rails, on large potholes, but not on small ones. The rod ends knock more clearly the more the wheels are turned out. With all the knocks around the wheels, you can drive, but not for long, it’s better to eliminate it. Engine These knocks are the most costly to the pocket, but least dangerous to life. There are seven of them, let's start with the most devastating: - The knock of the crankshaft liner is dull, metallic, coming from the very depths of the engine, at which the oil pressure, as a rule, drops. It can be heard more clearly if you bring your ear closer to the oil filler neck with the plug removed, of course. Elimination costs (engine overhaul) will range from 1/2 to 2/3 of the cost of a new engine. — The knock of the camshaft liner is louder, the oil pressure does not drop. There is no point in listening to it through the filler neck, because it can be heard even two meters from the car with the hood closed. Repairs will cost 1/8 the cost of a new engine. - The knocking of valves is nonsense, a “hussar runny nose”, which can be eliminated by adjusting the camshaft chain for 70 rubles. - The clanging of the camshaft chain (six, seven, some Volga models, the Ufa engine of the Moskvich) changes with changes in engine speed. If the clanging is not eliminated by adjusting (three minutes of work) the tension roller, then the chain has stretched and needs to be changed. Suspensions, transmission - A loud click under the bottom when starting from a stop and changing gears of rear-wheel drive Zhiguli clearly signals the need to replace the universal joints. — We have already talked about the knocking of shock absorbers - it’s easy to check whether each of them works. To do this, you need to strongly pump the corresponding wing - if the car does not “settle down” after the first swing, change the shock absorber. — On rear-wheel drive cars, the hum of the rear axle gearbox increases when the gas is released and decreases when the gas is increased. Moreover, it sounds somehow “under the ceiling”, above your head, which is different from the noise of the gearbox, which comes from below. — The noise of the clutch release bearing can be easily diagnosed by pressing and releasing the clutch pedal - it appears and then disappears. With all the unkind sounds of this third section, you can travel thousands of kilometers. It’s not for nothing that only Russian motorists have a saying: “A good knock will come out sooner or later.” But where will he come out - what if, God forbid, far from any civilization? Body Still, the most unpleasant and common sounds are the rattling of body parts: lock rods and door handles, the insides of the “torpedo”. You can, of course, catch these sounds, like a flea on a sofa, by placing a friend in the back seat: if you press it, it won’t knock. But it is better to use a radical method - disassemble, glue the rods and parts with foam rubber and sheet mastic. For those with strong ears: plug in and listen! Finally, I will give you a wonderful method of “field” sound diagnostics, which I adopted from athletes. Remove the oil dipstick, wipe its curved end with a clean cloth, insert it into the shell of your ear, and slightly wrap the ear itself, pressing the end of the dipstick with it from the outside. Press this entire structure with your palm to your head and carefully, being careful of the rotating parts of the running engine and electrical wires, place the end of the probe on various units - what does it feel like? So many sounds, right? And how different they all are... Now you know them all - good luck on the roads!

Suspension knocks and creaks. How to fix

Extraneous sounds often occur in the suspension and shock absorbers. These are knocks and creaks. Most often this is present in the front part of the suspension. Moreover, the reason does not necessarily lie in the rack itself. Sounds can be made by:

- Tie Rod,

- support bearing,

- spherical bearing.

Problems in these units arise more often than in shock absorber struts. Therefore, if extraneous sounds occur, you must first check them. Usually the problem lies in the bearing. Replacing it is not a problem even if you have no experience. A minimal set of tools is enough. The situation is similar with the ball joint.

But sometimes the problem lies precisely in the shock absorber strut. One of the common problems is that the bump stop makes strange sounds. It just falls down the stem. Which leads to squeaking.

The problem may lie in the strut washer: when it does not press the bushing of the support itself well against the bearing. It is necessary to immediately change the washers and supports at the same time. Creaking often occurs in certain situations. For example, on bumps. In this case, the reason in almost 1000% of cases lies in the shock absorber struts. There is only one way to fix this - complete replacement.

What to do if the shock absorber strut leaks: consequences

Shock absorbers leak due to their design: they are a cylinder that runs in a special sleeve. A special piston moves through a mass of oil or gas (or both at the same time - a combined type). The rod is fixed on it. Thanks to which there is no compression or stretching. The oscillation process itself takes place thanks to the jets.

They are small in size. It is for this reason that the rod moves a short distance, slowly. To prevent oil leakage, the gas outlet from the shock absorber in its upper part is equipped with special seals and gaskets. Thanks to them, the filling of the sleeve does not go beyond its limits. However, with severe wear, oil begins to gradually ooze out. This is due to the following details:

- stock,

- gaskets

The presence of leaking oil indicates that the part is gradually failing or has already failed! A leak indicates that the shock absorber has already exhausted its service life. It needs repair or replacement. A leak is an obvious sign of a suspension problem. Many people ask the question: is it possible to operate a car in this condition? There is no clear answer to this.

For example, if only one rack is out of order, then it is possible to use the car for a short time. But if the struts fail in pairs (two in front or behind), then it is better to stop driving until they are replaced. Because otherwise the car will “toss” along the road like on a roller coaster. Moreover, regardless of the speed of movement. Sudden maneuvers can lead to an accident. Moreover, replacement is best done immediately when the above symptoms occur.

Basic recommendations:

- if one rack is leaking, then use the car for a while without heavily loading the body, perhaps

- If 2 or 3 struts are leaking, you need to drive extremely carefully, at low speed and only to the nearest car service center!

When choosing shock absorbers you need to be careful. One of the compromise solutions in terms of price-quality ratio today is KAYABA.

Causes of shock absorber knocking

So, if everything is in order with the bushings, why might the shock absorber be knocking?

Yes, imagine there is oil in the shock absorber. (joke).

Carefully inspect the shock absorber that is knocking. If there are oil leaks on its outer side, then immediately buy a new shock absorber, or better yet two, to replace them on one side of the car.

There is a knock, but there are no external signs of oil leakage.

In this case, there may be several reasons for the shock absorber knocking.

The first thing to do is simply rock the car by pressing on the surface of the car in the place that is located above the suspicious shock absorber.

The swinging should immediately stop smoothly.

If smooth vibrations occur for a few seconds, then that’s it, the shock absorber is in trouble.

This means that the shock absorber knocking occurs due to some internal damage. This could be a broken thread or even a slightly bent rod, or the shock absorber pipes are disconnected. In general, mechanical damage and breakdowns.

It is not recommended to repair the shock absorber in these cases; it is better to replace it.

Internal oil leak.

In addition to external oil leaks, there is also an internal leak, which is when oil from one cylinder, the internal one, flows into another, the external one.

As they say, a holy place is never empty, the oil has gone, the air has come. The airy area of the shock absorber can be eliminated and the knocking noise will stop.

You can do this either yourself or at a car service center. It all depends on the shock absorber model, i.e. This problem can be solved and there is no need to buy a new shock absorber.

What consequences await the driver when using the current struts?

Many people wonder: is it possible to drive and what are the possible consequences? When operating a vehicle with 2-4 failed shock absorbers, the following consequences will occur:

- the rest of the suspension parts will gradually fail, the body may “behave” - since the buffer in the form of a piston that absorbs shocks and vibrations will be absent,

- the suspension will take the shock and gradually all kinds of rubber components (silent blocks, bushings and balls) will fail - as they will absorb vibrations,

- the distance from the bottom of the car to the ground will be less - which can lead to damage on large bumps (for example, the muffler will simply tear off).

In addition to all other troubles, a decrease in controllability will also be added - it will drop significantly. If a leak has just appeared in the rack, but the oil has not yet had time to leak out, then it will work normally for some time. In terms of time, about 1-2 weeks, no more. If you use a car for a long time with faulty shock absorbers, this can lead to uneven wear of the rubber. Since there will be a skew of the body.

It is not recommended to drive at high speed even with one shock absorber not working. Controllability is significantly reduced, and there is a high probability of getting into a traffic accident. Moreover, the insurance company can easily refuse payment citing a car malfunction. Therefore, it is important to be careful when using a car with suspension problems. And this applies not only to shock absorber struts.

When the first signs of malfunction occur, it is necessary to replace it with a new one. It is advisable to purchase the original. Their resource is an order of magnitude greater, as is their quality.

Why is the new shock absorber knocking?

If a knocking noise occurs in the suspension after replacing the shock absorber, this may indicate a defect in the new part. It is necessary to check the new shock absorber for defects in the rubber bushings (or their mismatch in size), for reliability of fastening (it is important to tighten the nut sufficiently, otherwise the part will “move” when the car is moving), for possible malfunction of the damper and other defects.

It is worth noting that a defective shock absorber from the factory is an extremely rare situation, especially when it comes to parts from well-known manufacturers.

( 138 votes, average: 4.39 out of 5)

Brake calipers squeak and jam: causes, repairs, diagnostics

How to check and replace engine mounts