Fans of long trips are interested in learning how to make car roof boxes with your own hands. Modern cars, for all their advantages, have rather small trunks. Therefore, many drivers are forced to use various additional devices. Most often, autoboxes are used. They allow you to transport various loads on the roof.

This way, you can transport things without fear of getting them dirty or wet. Also, unlike conventional frame racks, car boxes are more aerodynamic.

Types and types

How to make car roof boxes with your own hands? First you need to decide on the type of trunk. The materials used and the complexity of assembly depend on this. The final choice of variety is influenced by the cargo that is planned to be transported.

Car boxes differ mainly by the type of fastening. The most familiar to domestic motorists is the drainage ditch. It can be found on many cars, located along the edges of the roof. Usually, ordinary luggage racks are attached to them, this is done using clamps with bolts. Some models have roof rails. This allows you to install fairly large car boxes on the roof. For completely smooth roofs there are special fastenings.

Based on their length, boxes are divided into 3 groups:

- Short ones

- occupy about a third of the roof; - Medium

- they are slightly more than half the length of the roof; - Long

- equal to the roof or slightly longer than it.

Here the choice depends on your needs. If you plan to transport a small number of small items, then the short option is ideal. For trips with the whole family, it is best to use medium-sized luggage racks. Long ones are ideal for transporting skis and other similar equipment.

Bike rack on towbar and traffic rules

I have a question for the respected community:

The car has a towbar. A bike rack is attached to it, and bicycles are mounted on it.

Problem: the license plate is not visible on the car; in principle, Gaia may become attached to this. There is a landing pad on the trunk, about which there is even a page in the instructions: draw a number!

Explicit solution. Correct.

The lights are connected. This is the standard.

About the license plate: I loaded the car, took the license plate, attached the trunk, attached the bikes, attached the license plate. I arrived, rented a license plate, took off my bikes, removed the trunk, attached the license plate, and locked the car. I went for a ride (along the Gulf). I decided to drive further/closer. He opened the car, took out the trunk, and took off the license plate. I attached the trunk, attached the license plate to the trunk, attached the bikes.

How is the number attached? In a week or two you'll be tired of rearranging.

You can’t do a third number - they’ll put you in jail. Make a dummy and write Copy or marker - not a standard sign - fine.

It’s not a big problem, 50 rubles, but I want to solve it fundamentally and in such a way that it doesn’t get ugly.

By the way, can anyone tell me what kind of mechanism for quickly fastening the license plate, like an eccentric or something else? With a secret, so as not to sleep?

Once he asked Gaius a question, he was afraid that he would get angry - he wrinkled his face, began to move his hands, muttered under his breath and did not react to those around him.

How to do it?

First, decide on the mounting method. The design of the base largely depends on this. The cross members must end with fastenings. To determine the appropriate type of fastening, simply look closely at the car. After that, purchase the necessary items.

For the base you should use a lightweight but durable material. Aluminum or duralumin channels are best suited. This makes the structure not only durable, but also lightweight. Which will have a good effect on the efficiency of the car. The parts of the base are assembled together using bolts. The result is reliable and can be quickly disassembled if necessary. Also, something is usually attached to the base to stiffen the load. Polycarbonate is best suited for this.

Aluminum composite panel can be used. A bead should be made on the sides. It is usually made from the same material that is placed on the base. It is attached either with special locks or rivets. It all depends on the material.

Any material can be used. Most often they use something like a tarp. For greater aesthetics, you can take banner fabric. She is quite flexible. At the same time, it does not allow light and moisture to pass through. At the same time, you can order printing of drawings, which will make the car more attractive.

It is important to choose the right lock. Please note that if it is exposed to snow and ice, it will freeze in winter. Therefore, when cutting fabric, provide a safety valve. You should also use zippers designed for skiers.

Assembly

. First you need to cut the fabric into fragments. After which they are sewn together. It is better not to use ordinary threads. Instead, it is better to use fishing braid or fishing line. This will give the seams greater reliability. It is better to do zippers from the side of the roadside. This way it will become less dirty. And unloading will be more secure.

Nets for dogs

Dividing net for transporting dogs

When transporting dogs in the luggage compartment, you can use a regular or special type of mesh. The optimal solution for a car with a station wagon, minivan or hatchback would be a separating net or a separate product designed specifically for transporting dogs. Moreover, these two accessories perform the same functions. The accessory does not allow the dog into the car interior and allows it to move freely in the trunk space.

There is another model that limits the movement of the animal directly within the luggage compartment. This playpen net is a universal product and is suitable for all cars. The only negative is the lack of an upper part through which a large animal can easily get out. Otherwise, this product copes with its functions perfectly and traps wool perfectly.

There are also modifications for transporting animals in a lying position. They are attached to the bottom of the trunk and pulled over the dog. Elastic fabric is used in the manufacture of this accessory. The size must be selected individually so that the dog is comfortable.

Additionally

Take the time to add a little lighting to your expedition rack. To do this, install a pair of white LEDs in front. They are connected to the car lighting. When the low beam is turned on, they will also light up.

This is done for greater traffic safety. On a night road, a car with such a design is visible much further. This is especially true for highways with a large number of descents and ascents. Oncoming drivers will switch to low beam in advance, which will protect you from being dazzled.

Options for attaching dividing, floor and vertical grids

Vertical mesh for trunk niche

There are several ways to secure the trunk net:

- Using standard fasteners. They are provided by the car manufacturer when designing the luggage compartment.

- For special technological holes.

- On the back of the seat where its vertical position is fixed.

Types and photos of the most common designs

There are four main types of car racks:

- Classic. Otherwise they are called universal or basic. They are a structure of metal crossbars and crossbars fixed to the roof of the car. Their main advantage is the ease of fastening and the possibility of modifying the design for transporting sports equipment or installing a car box.

- Expeditionary. This type is designed for fans of outdoor activities, tourists, as well as hunters and fishermen. This cargo compartment is more like a basket. In addition to the base, it has sides to which you can attach lighting fixtures, bump stops and spare tires.

- Bicycle. The design is a system of fasteners that secure sports equipment.

- Autoboxes. They are hard and soft. Hard roof cases are made of impact-resistant plastic, while soft ones are made of fiberglass and look like large travel bags. A fiberglass car box is the best option for an experienced traveler, because the things transported in such a trunk are reliably protected from dirt, wind and precipitation. In addition, the design has a good aerodynamic shape and does not increase fuel consumption too much when fully loaded.

Nets for transporting things

Floor mesh in the trunk

Taking into account the functional purpose, method and location of installation, car nets are divided into several types. Depending on the location they are:

- Vertical. They press objects tightly directly against the walls of the trunk, thereby eliminating the possibility of unwanted movement. Such products help to effectively use vertical space along partitions or walls. At the same time, the main part of the luggage compartment remains completely free.

- Horizontal. Press things to the bottom of the trunk. Nets of this type reliably secure the transported cargo. Even when overcoming difficult sections of the road, objects remain in their places.

- Small vertical ones. Allows you to close empty niches. Thanks to this accessory, you can place containers with tools or automotive chemicals in niches. Nets are also installed on the vertical walls of the trunk. They function as regular pockets.

- Universal. Mounts absolutely anywhere. This could be the floor, seat back, side niche or wall. Installation is carried out using hooks or regular Velcro. They are often small in size and able to fit tightly around objects. By securing such a product inside the trunk of a hatchback or station wagon, you can significantly save space.

DIY car roof rack

To make a car roof rack with your own hands, you need certain skills and equipment. The work takes place in several stages:

- Preparation: determining the design of a roof rack for a car, taking measurements and drawing up a drawing of the future product, purchasing materials.

- Production: production of parts and fasteners, assembly.

- Fixation: fastening longitudinal and transverse strips, installing a ready-made trunk or car box.

The main factor when choosing a trunk design is its purpose. If there is a need to transport not heavy, but large-sized cargo, then a universal or forwarding type is suitable. For those who want to free up space in the car from things that are not most often used, but necessary, a car box is the ideal solution.

Attention! However, making a box for the roof of a car yourself is not so easy, so classic or expeditionary roof racks are more popular among handmade lovers.

Selection of material and tools

When making a trunk, it is necessary to take into account the fact that the maximum load on the roof should not exceed 70 kg. The design will be much lighter if aluminum profiles are used for its production. They are lightweight, flexible and durable, which combined with their low weight makes this material ideal for achieving the goal. An alternative solution could be thin-walled profile pipes. They are also durable and corrosion resistant, but their cost is almost 2 times lower than aluminum.

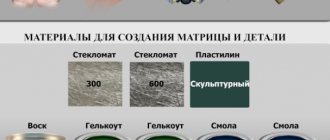

If you still want to make a car box, it is better to opt for a soft design, because making a case from fiberglass is technologically difficult and expensive. The material for soft boxing is tarpaulin or banner fabric, or fiberglass with a density of at least 300 g/m2.

In addition, you will need the following consumables and tools:

- bolts and clamps;

- polyurethane foam;

- grinder for metal;

- welding machine;

- Sander;

- primer and car paint.

It is not necessary to match the paint to the color of the car, especially. The design can look aesthetically pleasing even without painting.

Design measurements and drawing

If the design of the machine provides for roof rails, then to make the cross members it is enough to simply measure the distance between them. If they are absent, you will have to make accurate measurements of the length and width of the roof, on the basis of which a drawing of the future structure will be drawn up. When drawing a 3D model, it is not enough to take into account only the dimensions of the perimeter of the cargo compartment. You will need the following additional parameters:

- height of side or box;

- place for attaching transverse jumpers and the distance between them;

- number of fastenings: if the roof length is more than 2.5 m, the structure must have 6 supports. For smaller sizes, four are enough.

As a basis for a pattern for a soft box, you can take drawings that are publicly available on the Internet and adapt them to the desired size. The designs for expeditionary roof racks are quite simple, and you can make them yourself, but it’s easier to start from ready-made solutions.

Expeditionary trunk type "basket"

The technology for manufacturing an expeditionary trunk will be much more complicated. In this case, you will need to first draw up a drawing. In addition, you cannot do without a welding machine and the ability to handle metal.

Mesh base - a practical solution for expedition luggage

Construction drawing

Let's take a homemade trunk for a Chevrolet Niva as an example. The length of the trunk will be 163 cm, width - 123 cm. To make an expedition trunk, you will need a metal profile 15X15 (approx. 9 linear meters), 20X20 (approx. 7 linear meters), 25X25 (approx. 7 linear meters) and 30X20 (approx. 6 p.m.).

It’s quite possible to make an expedition rack for Niva using this drawing yourself

Sequence of actions of the wizard:

- We start making the trunk from the base: we cook the perimeter. Longitudinal guides are made from profile 30X20, transverse jumpers are made from profile 20X20.

- We weld load-bearing lintels from a 30X20 profile into the perimeter. For them the platform will be attached to the rails.

- We reduce the distance between the load-bearing jumpers by welding additional transverse ones from the 20X20 profile.

- We make an arc that will be located in front in order to improve aerodynamics: we measure 5 cm from the edges of the profile and cut out a triangular sector, after which we bend the profile. We weld the arc on the outside of the perimeter.

- To increase the strength of the structure, we fasten the jumpers together with sections of 15X15 profile. If desired, non-load-bearing lintels can be replaced with metal mesh or stainless steel sheets.

- We make the sides. We cut the profile into pieces 6–10 cm long and weld it to the base. If desired, they can be mounted on a thread - then the sides and the upper part of the trunk can be removed.

- It was the turn of the top crossbar. It should be the same size as the bottom one, but the side crossbars should be slightly shorter, and the posts connecting them to the base should be angled to improve aerodynamics.

- We fasten the trunk in a manner similar to that described above. An important point: to evenly distribute the weight, the expedition rack should be secured to six points.

Article on the topic: Peculiarities of operating diesel engines - how to survive the winter?

If the car does not have roof rails, you will have to make the supports yourself from a piece of sheet metal. You can put it on brackets, but to do this you will have to drill into the body.

The expedition trunk has increased functionality compared to a regular trunk. For example, you can attach fog lights to it - just weld the headlight mounting bracket to the inclined connecting element at the front (see point 7).

In addition, it is convenient to carry a shovel in the expedition trunk. It can be secured using a conventional pipe fastener.

Video: fastening the structure to an SUV

Advantages and Limitations

The advantages of mounting a bicycle on a tow bar are obvious:

- aerodynamics – the bicycle is not located above the roof and has little effect on the aerodynamics of the car;

- ease of installation - although installing the bike in the holder requires lifting it 20-40 cm from the ground, this is not placing the bike on a car at your own height, and does not require special forces;

- cost – mounting on a tow bar is usually inexpensive, since the designs used are as simple and reliable as possible. In addition, such a holder is easy to make with your own hands;

- free roof - you can install a full-fledged car rack or case on the roof rails.

There are also disadvantages, and first of all these are problems with control: you need to go over all the bumps very carefully, since light bikes do not always hang on a kind of lever, and sudden movements can damage the equipment. For transportation, changes in dimensions also play a role. On narrow budget cars, bicycles will peek out over the edges of the body, while even on large cars, the additional 50-100 cm of body length poses a danger when braking, taking tight turns and moving backwards.

In addition, there are other disadvantages:

- contamination of the frame and mechanisms - during transportation the bikes are not covered, and dirt thrown from under the wheels of the car may appear on all components;

- the need for a towbar, which not all cars are currently equipped with;

- less reliable fastening - not all towbar brackets are reliable and well mounted enough to withstand the dynamic loads that arise when driving with such a load as 3-4 bicycles.

Manufacturing of fasteners

The easiest way to make your own mounts is to remake the clamps for attaching the muffler from almost any car. They look like a flat bracket on one side and an arc going around the pipe on the other. We need to saw off the excess so that we are left with a flat plate. It will fit snugly against the crossbars and roof rails, providing reliable fastening. To prevent the clamps from standing out, it is advisable to paint them the same color as the trunk - the look will be more pleasant.

If you don’t want to be tricky with clamps, then you can use U-shaped brackets with threads for this. And instead of ordinary nuts, use wing nuts that can be quickly unscrewed and tightened. This solution will significantly speed up the process of installing the trunk.