Models of fuel pumps for VAZ 2114/2115 cars

VAZ 2114/2115 cars are equipped with 1.5 cm3 and 1.6 cm3 gasoline engines with a distributed injection system. A submersible electric fuel pump is used to supply fuel. It is part of the fuel module installed at the top of the gas tank (under the rear seat). In addition to the pump, the module includes a fuel accumulator (cup), a coarse filter and a fuel level sensor with a float.

The VAZ 2114/2115 fuel pump is a conventional DC electric motor in a sealed housing with a one-way valve at the outlet. An impeller of a special shape is located on the electric motor shaft. Its rotation ensures the fuel supply.

The fuel pump is powered from the vehicle's on-board network. The electrical circuit of the pump, protected by a fuse, is closed using a separate relay.

Electric fuel pumps for VAZ cars are produced by both domestic (Utes, SAAZ, Pekar) and foreign companies. The latest modifications of the VAZ 2114/2115 are equipped with BOSH pumps, which are distinguished by their high reliability, long service life and relatively low price.

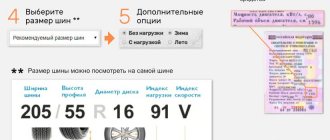

Catalog numbers of standard fuel pumps for VAZ 2114/2115:

- 2112–1139009–12 — for engines with a volume of 1.5 cm3;

- 2112–1139009–01 — for engines with a volume of 1.6 cm3;

- 580453453 (BOSH) - for engines with a volume of 1.5 and 1.6 cm3.

These models differ in operating pressure. The former are capable of creating a pressure of 2.8–3.2 kPa in the fuel system, the latter - 3.7–3.9 kPa. BOSH fuel pumps are rated at 3.5 kPa.

Checking ground, relay and fuse

In the VAZ 2114, the ground contact is located under the dashboard panel not far from the parking brake lever, which determines the high risk of damage to it. A good sign of a faulty contact is a non-functioning fuel level sensor. The normal state of the contact is restored after it is cleaned and reinstalled.

Next to the ground contact there is a relay R2 of the fuel pump, which is used to create the required pressure in the gasoline system when starting the engine. Due to the low cost of this component, if it fails, it should be immediately replaced with a new one. A relay malfunction can be detected by simply reversing it.

The fuse is located in the box under the hood on the windshield side. The fuel pump is the one marked Fuel Pump 15A. The blown fuse is replaced with a new one.

Buying a fourteenth fret is a young thing that does not require a large budget, both for the car itself and for spare parts. If you compare the VAZ 2114 with any foreign car of the same class, you will get a decent price difference in favor of the Lada. And even if a foreign car costs more, and servicing it is not more expensive than a Lada, then spare parts from the Russian automobile industry will be much easier to find in any of the most remote areas of our country.

Whatever you say, any car wears out and requires attention and care. So let's talk about a common problem with the fourteenth - the fuel pump does not pump.

Gasoline pump VAZ 2114

Situation

You're driving, and suddenly you stall. You start it, the engine growls, the starter turns, it starts moving and again there is a stupor. Or the ignition does not respond at all, you have to push it to start. This also includes the case when the engine responds every once in a while if you slow down for a couple of minutes and go to nitral. The battery is ok. We're sinning at the fuel pump.

Symptoms of a problem

A malfunction of the fuel pump of VAZ 2114/2115 cars can be diagnosed by the following symptoms:

- when the ignition is turned on, there is no sound of the pump running;

- the engine does not start or starts with difficulty;

- the power unit is unstable at idle, the speed “floats”;

- “dips” appeared during acceleration;

- the motor has lost power.

The same signs also appear when other elements of the fuel system malfunction.

Before you begin diagnosing or replacing the fuel pump, you should make sure that:

- the fine fuel filter is not clogged (it is changed every 7 thousand kilometers);

- the injectors and fuel pressure regulator are operating normally;

- The sensors for mass air flow, throttle position, and oxygen quantity are working properly.

If the detected malfunction is accompanied by the lighting of the “CHECK” lamp on the dashboard, you should set the error code and decipher it.

Fuse

One of the final stages of checking a malfunctioning fuel pump is its fuse. Like the relay, the fuse can be seen from the inside. Or you can climb in from the outside, through the hood. Under the hood, closer to the windshield, there will be a dark box, right on the electronic control unit. You need to open it and find the topmost fuse with a current of 15 A and the English inscription fuel pump. We take it out and look at the insides: the contact is not damaged - the fuse is alive. The contact is damaged (blown) - you need to install a new fuse. As with the price of the relay issue, buying and replacing a fuse will not be a big waste of money and time.

Not every master's hands grow from the right place. For this reason. The reason that the fuel pump does not pump can be simple stupid shortcomings of simple tuning.

For example, the alarm was installed in such a way that all the contacts were mixed up, and power simply does not go to the fuel pump. Not because the alarm should not be on the car, or the wiring system is acting up, it’s just that the person who installed it didn’t have enough brains and practice. Check all connections carefully if you decide to add some style to your little one.

Or anti-theft. The button is placed in such a way that it interrupts the integrity of the fuel pump ground contact system, and almost always fails. By the way, if you have such a lotion, I don’t think it will be very effective in the absence of a signal. And if there is a signaling system, then anti-theft is not needed at all.

In any case, remember: in any situation where a VAZ breaks down, the point is not that it is a VAZ, and it was made poorly. It’s just that the Russian auto industry is a little more delicate than the foreign one, it requires a little more attention and your ingenuity.

Heading

Every modern fuel supply system installed on an automobile internal combustion engine contains an electric fuel pump in its design. This device can be installed either directly in the gas tank or next to it under the bottom of the car. The VAZ 2114 electric fuel pump injector is a submersible equipment and is installed in the gas tank.

Checking the electrical circuit

At the beginning of the diagnosis, you should check the electrical circuit of the fuel pump. To do this you will need:

- car tester (multimeter);

- crosshead screwdriver;

- two pieces of wire about 2 m long.

Checking the electrical circuit is carried out in the following order:

- Turn on the ignition without starting the engine. When the key is in the first position, a click should be heard, characteristic of turning on the relay, followed by a slight whirring of the pump electric motor. If there is no click, the relay is faulty or is not receiving power. If there is a click, but no buzzing, the wiring coming from the relay or the pump motor itself is faulty.

- Under the glove compartment, find an additional mounting block consisting of three relays and three fuses. The pump relay is located in the middle, and the fuse is located to the left of it. Remove the fuse from its socket, test it with a multimeter, and if the result is negative, replace it. When replacing the fuse, please note that it is rated for a maximum of 15 A.

- Set your multimeter to voltmeter mode. Connect one probe of the device to the relay terminal to which the pink wire fits, and the second to the car body. Turn on the ignition. The device should show the on-board network voltage in the range of 11.7–12.4 V. If there is no voltage, the problem may be a broken wiring or a malfunction of the ignition contact group. In this case, it is better to contact an auto electrician. If power is supplied, check that the relay is working. With the ignition on, use a screwdriver or a piece of wire to close the contacts to which the pink and gray wires go. This closes the circuit bypassing the relay. If the fuel pump works, replace the relay.

- Be sure to check the connection of the pump's negative wire to ground. Often it is the lack of “ground” that causes interruptions in the operation of the fuel pump. Remove the plastic trim from the center console near the parking brake handle. Under it there is a “negative” wire of the pump, screwed to the body with a self-tapping screw. Unscrew it, clean the contacts, screw it back and repeat the test.

Checking the wiring contacts and serviceability of the electric motor

The first thing that is checked after a fuel pump failure is the supply voltage to the unit. This procedure is carried out using a conventional 12-volt probe light bulb. The light bulb is connected to the positive (gray and black wires) and negative contacts of the pump, after which the ignition is turned on. The light coming on for 3 to 5 seconds at this moment indicates that the wiring is working properly.

The voltage at the fuel pump terminals is checked with a tester and should be more than 10 V. A drop below this value indicates oxidation of the contacts and an increase in resistance. The malfunction is eliminated by cleaning. Both contacts are checked.

Then, using the same light bulb, the serviceability of the electric motor is checked. To do this, the contacts of the improvised probe are connected directly to its terminals. A burning light with the ignition on and the engine stopped clearly indicates a failed electric motor.

Pressure check

If the pump is working properly, but the engine begins to operate intermittently, you should check the fuel pressure in the system. For this you will need:

- pressure gauge (can be a tire gauge with a measurement limit of 5–7 kPa);

- petrol-resistant hose with a diameter of 10–12 mm and a length of 50–80 cm;

- two clamps for a hose of the appropriate diameter;

- Phillips screwdriver;

- nipple cap;

- dry rag.

In addition, the presence of an assistant is desirable.

The verification procedure is as follows:

- In the engine compartment on the engine fuel rail, locate the pressure measuring fitting (on the right side).

- Remove the plastic cap (plug) from the fitting.

- Using the nipple cap, unscrew the spool valve from the fitting. When unscrewing the spool valve, fuel may spray out of the fitting. To remove it, use a dry cloth.

- Place one end of a gas-resistant hose onto the fitting and secure the connection with a clamp. Connect the other end of the hose to the pressure gauge fitting and also tighten the clamp.

- Ask an assistant to turn on the ignition. Wait a few seconds and watch the meter readings. If the pump is working properly, the pressure gauge should show a pressure of 2.8–3.2 kPa for engines with a volume of 1.5 cm3 and 3.7–3.9 kPa for engines of 1.6 cm3. If the pressure is noticeably higher, the pump is faulty.

Motor

We checked the pressure and wiring, everything works like clockwork, but the engine stalls. The fuel pump may not pump due to a breakdown of the motor - the main element that drives fuel. We check its functionality with the same light bulb: attach its wires to any terminal of the motor, turn the ignition. The lamp blinked - it was time to throw out the motor. And again, run to the store for a brand new motor.

The terminals may oxidize and not make contact, as a result of which the fuel pump will not pump. The motor in this case may be normal. And the terminals just need cleaning (possibly re-soldering). There is an opinion that the terminals are oxidized due to low-quality fuel (the octane number does not match the declared one).

Replacing the fuel pump VAZ 2114

The gas pump can fail at any time and the quality of the fuel at our gas stations contributes to this. You can determine whether replacement is needed by measuring the pump pressure in several modes. For different fuel supply systems, the pressure is different, so you must use the manufacturer's manuals. There is also a universal way to check the pump, the so-called “wall pressure” - measurement with a pinched return line or directly into a pressure gauge. The pump, in this case, must “press” at least 5.0-5.5 atm.

Popular breakdowns

Problems with the fuel pump can occur for several reasons. Therefore, your first priority is to determine the source of the problem. These may be:

If one of these elements fails, it can stop the normal functionality of the entire module.

Let us consider the situations with each of the specified elements of the fuel module in more detail.

Pressure

What exactly is a fuel pump? This is an element of the fuel system that allows fuel to pass through due to pressure. Therefore, if you take pressure measurements, you can get answers to many questions.

Let's give an example of normal pressure readings when checking in certain modes.

Check mode

Normal indicator

At idle

Without pressure regulator tube

When the drain is pinched

When you press the gas pedal

We recommend measuring with a small range of atmospheres on a pressure gauge (up to 7 atm). This will reduce errors to a minimum. Having a pressure gauge at hand will allow you to significantly save on professional diagnostics.

Contacts

The fuel pump includes three wiring:

- Plus (positive);

- Minus (negative);

- Fuel level indicator.

So, failure of the pump may occur due to a simple violation of the integrity of the wires. So if the pressure check shows normal, then we definitely examine the condition of the wiring.

To check, you will need a 12V lamp, which is attached to the external connectors of the pump with positive and negative contacts. Turn the ignition key. If the lamp blinks, contact is present. In this case, you will have to check the condition of the internal contacts.

Checking contacts

Motor

If the pressure and wiring are normal, let's try to check the serviceability of the motor. It is this element that is responsible for moving fuel through the system.

- To check it, you will need the same 12V lamp;

- Attach it to any motor terminal;

- Turn the ignition key;

- If the lamp blinks, you will have to get rid of the motor and buy a new one.

Motor

Don't jump to conclusions. Before checking, look at the condition of the terminals and motor wiring.

Fuel pump weight

The contacts are fine, but the fuel level sensor may provide incorrect information. In this case, you definitely need to check the weight of the pump responsible for dispersing the fuel.

It often turns out that after prolonged use or driving on difficult road sections, the mass simply loses its fastening strength. Accordingly, if the mass falls off, the pump will not be able to work.

The mass is attached to the pump under the dashboard in the area of the hand brake. Therefore, when the driver turns on the handbrake, there is a possibility of hitting the ground contact, which is why it will fall off.

Putting the mass back in place is not that difficult. The problem is caused by the path to it. You'll have to:

- Get to the bottom through the interior;

- Remove the plastic under the handbrake;

- Remove the floor covering;

- Remove the grounding contacts;

- Clean;

- Secure it to the fuel pump as firmly as possible.

Weight

The fuel pump relay is located exactly where the ground is. Therefore, there should be no problems with the search.

With an ideally working fuel supply system, when the ignition is turned on, the relay instantly creates pressure inside the system, and then turns off.

If this process is disrupted, you will have to:

- Lift the front facing panel, which covers the contacts of the audio system and air conditioning;

- Take a look from the front passenger side;

- Find three relays;

- The lowest one is our desired pump relay;

- Turn the ignition key;

- If you hear a characteristic click from the relay, it is working properly;

- If there is no click, check the contacts. The reason is either them or a failed relay.

Fuse

All that remains is to check the condition of the fuse. This stage will make sure who the real culprit of the problems is - the pump itself or its fuse.

As an example, let's take the replacement of a VAZ 2114 fuel pump

To replace the fuel pump you need to:

- remove the rear seat;

- find and unscrew the gas tank flap;

- disconnect the connector from the fuel pump;

- start the car at idle speed (to relieve pressure);

- unscrew or snap off the supply and return fittings;

- unscrew the fastening of the pressure plate of the fuel pump housing;

- remove the assembly (to prevent spillage of residual gasoline in the cabin, you must use a rag or a cardboard box);

The VAZ 2114 fuel pump module is disassembled as follows:

- it is necessary to remove the stopper from one of the guides;

- hold the fixing plates and disconnect the module;

- remove the fence mesh;

- disconnect the connectors and chips from the pump and fuel level sensor;

- remove the corrugated fuel line (during the first disassembly, this will be difficult to do, since the fuel supply pipe is seated “hot”; some force must be applied);

- All that remains is to remove and replace the fuel pump itself;

Assembling the VAZ 2114 fuel pump occurs in the reverse order, in compliance with the following rules:

- be sure to install a new fence mesh;

- plastic parts of the module must be cleaned of dirt and sediment;

- You need to put a clamp on the corrugated fuel line.

When compressing this clamp, it is necessary to monitor the force, since there is a fuel dump check valve in the outlet fitting of the pump. Excessive crimping force can damage the valve and disrupt the operation of the entire fuel system.

- installation of the module in the gas tank should be carried out according to the marks located on the body;

- after installation, you should start the engine and check the connections for leaks and the functionality of the fuel level sensor;

It should be noted that replacing the VAZ 2114 injector fuel pump, which consists of several design options, is carried out according to a similar principle. A small design difference consists only in the appearance of the module and the receiving cup.

- If the module is installed on screw-in fittings, it is advisable to replace the rubber rings located at the supply and return ends (the rings must be petrol and oil resistant).

- When replacing the fuel pump of a VAZ 2114, it is also necessary to replace the fuel filter.

- Before dismantling the fuel pump module, you need to unscrew the gas tank cap (to avoid discharge during removal).

- The amount of gasoline in the tank should not exceed half the level.

- When replacing a fuel pump, you should naturally follow the requirements of fire safety regulations and be sure to have a proven powder fire extinguisher nearby.

Fuel pump weight

The contact system is normal, but the gasoline level sensor is acting up. Let's see what happens to the mass of the fuel pump. It may be poorly secured. In this case, the fuel pump will not be able to pump anything.

The mass of the fuel pump itself is attached to it in the area of the handbrake, under the dashboard. When you pull the handbrake, you can touch the ground contacts of the fuel pump, and the connection may be lost.

It is not difficult to tighten the mass of the fuel pump, it is difficult to reach it. Namely: get the grounding contact of the ground conducting the lost connection. We remove the plastic under the handbrake and the floor covering of the car, respectively; We clean the contact and firmly attach the mass to the fuel pump.

In the same place as the fixed mass of the fuel pump, under the dashboard, its relay is located.

Ideally, when ignited, the relay creates the required pressure in the system in a couple of moments and turns off. If this does not happen, the pressure is normal, but the process does not proceed, we completely lift the front facing panel that covers the contacts of the music and air conditioner and look from the passenger side: there are three switches, the lowest one is from the fuel pump. When you turn the key, the relay makes a characteristic click and works. If there is no click, the relay or its contacts are closed.

As they say, there is no need to waste time on trifles, if the motor terminals can be reanimated, then it is better to replace the relay and its contacts. The pleasure is inexpensive, the location for replacing spare parts is very convenient.

Replacing the fuel filter on a VAZ 2114

Car maintenance is a prerequisite for accident-free travel. The manufacturer indicates the composition and frequency of work. Traditionally, preventive measures are associated with mileage. The list begins with diagnostics, replacement of consumables, and worn parts. Saving on little things can lead to failure of the main components and assemblies. The article discusses replacing the fuel filter on a VAZ 2114.

When is it necessary to replace the fuel filter on a VAZ 2114

Injection equipment is critical to the quality of gasoline. The fuel system contains coarse filters (built in with the submersible pump), fine filters (installed in the gap in the fuel hose). Manufacturers of the VAZ 2114 recommend changing the gas filter after 30 thousand kilometers. Amendments include the condition of roads and the quality of petroleum products. The frequency of technical inspections can be halved.

A clogged filter element causes:

- loss of engine power;

- the engine choke when the load increases;

- there are clear signs of a lean fuel mixture;

- The car reacts poorly to the accelerator pedal and moves jerkily.

The described symptoms can also be caused by other malfunctions. If checks of the electronic control unit, ignition, sensors, and engine adjustments do not bring a positive result, it’s time to change the gasoline filter on the VAZ 2114.

There is a testing method by measuring the pressure on the ramp with a pressure gauge. The deviation of the needle readings from the factory values indirectly confirms the guess. Installing a new fuel filter will bring complete confidence. An autopsy gives one hundred percent confidence - leave the removed part in a draft for a week, carefully saw it with a hacksaw, get acquainted with the inner world, clarity will appear.

Operating principle of an electric fuel pump

The functional work of the fuel pump is to supply fuel to the injectors. For normal operation of the injectors and creation of the required pressure, the supply of gasoline must begin before the engine starts.

The operating principle of an electric fuel pump includes the following functions: from the gas tank, the pump supplies fuel under pressure through the main fuel filter to the injector ramp. Excess fuel supplied is returned back to the gas tank through a separate drain line.

The electric fuel pump is turned on by a special controller using a relay. When the ignition key is turned to the “starter” or “ignition” position, the controller instantly energizes the fuel pump switch relay, and as a result of the created pressure, fuel is supplied to the injectors.

If the engine does not start running within a few seconds, the controller turns off the relay until the engine is cranked again. After scrolling, the controller turns on the relay again, determining the start of rotation using the reference signal from the crankshaft position sensor.

Diagnostics of electric fuel pump faults

The service life of the electric fuel pump on the VAZ injector is quite long, but everything has its limit. Poor fuel quality primarily damages the discharge part of the unit.

An uncorrected fuel pump in a car prevents it from working at full power, and the engine also becomes unstable at idle. Due to a lack of fuel, when trying to start, the engine begins to “sneeze”, starts with difficulty for a few seconds or does not start at all.

It is quite easy to diagnose the problem when you turn on the ignition, and if you do not hear the characteristic sound of the electric motor running for a few seconds, then the pump is faulty.

Another available method is to check the pressure in the fuel system with a pressure gauge while the engine is running. But it is recommended to first replace the fuel filter in order to avoid distortion of the device readings.

A decrease in performance also indicates a pump malfunction; this is easy to notice when driving in 3rd or 4th gear. If, when you press the accelerator pedal, the car reacts with dips or does not react at all, most likely the fuel pump on the VAZ 2114 has failed.

Self-replacement of the electric fuel pump

The fuel pump on a VAZ injector, as a rule, cannot be repaired, however, like most electric fuel pumps.

Replacing the fuel pump yourself is not difficult and does not require special equipment or tools. You will need:

- Phillips screwdriver;

- ratchet with head at 7 and 10;

- key to 17.

The unit is replaced in the following sequence:

- The rear seat is removed. To do this, remove two plugs and, using a ratchet with a 10-mm head, unscrew the two bolts. After removing the seat, a slot in the sound insulation should open in the shape of the letter P. The fuel pump cover is located under it.

- Use a Phillips screwdriver to unscrew the cover, revealing the upper part of the fuel pump module underneath.

- The wiring harness suitable for the module is disconnected.

- Now you need to relieve the pressure in the power system. To do this, the car engine starts and runs until the fuel from the line is completely used up, that is, until the car stalls.

- The battery turns off.

- Using a 17 key, unscrew the fuel line tubes one by one.

- 8 nuts are unscrewed around the perimeter of the clamping ring. To do this, use a ratchet with a 7-mm head. The pressure ring is removed.

- The fuel pump module is carefully removed from the gas tank.

After the fuel pump module is removed, it is possible to either completely replace it with a new one, or replace only the electric fuel pump itself, but this will require disassembling the fuel module.

Replacing a gasoline filter on a VAZ 2114

The fine fuel filter looks like a cylindrical barrel filled with special paper (retains particles of dirt, rust, and debris larger than five to seven microns) and is attached to the bottom next to the gas tank under the luggage compartment. There are two built-in fittings along the edges, with input and output gas pipelines. There is a description of VAZ 2114 models with a filter device installed in the engine compartment.

For ease of work, it is necessary to install the vehicle above the inspection ditch, on an overpass, and use a special lift. No years of auto mechanic experience required. An attentive beginner can handle the task.

Procedure for replacing a gasoline filter

First step

- Relieve pressure in the pipeline.

- Remove the worn element.

- Install a new filter unit, fill with gasoline, and remove the air.

- There are options for completing the first step.

- Turn off the power to the fuel pump.

- Raise the rear seat. Open the metal cover of the technological hatch. Disconnect the power connector.

- Remove the fuel pump electrical circuit fuse.

The location of the fuse box is indicated in the album. There are three placement versions:

- on the torpedo air duct casing near the gear shift lever under the plastic cover;

- on the right side of the passenger side is the mounting block hatch (relays, fuses);

- There is a plastic box under the hood at the base of the windshield opposite the driver.

Start the engine, wait until it stalls.

Equalize pressure, bleed fuel.

- Manufacturers of the VAZ 2114 have provided for the installation of a spool valve on the fuel rail, similar to a wheel air valve.

- It is necessary to prepare, put rags.

- Disconnect the negative terminal of the battery.

- Eliminate the possibility of sparks, open flames, and smoking.

- Remove the plastic protective cap.

- Using the nipple cap, slowly unscrew the spool, gradually reducing the pressure.

Second step

- While under the car, pay attention to the direction of the filter arrow (remember or mark it with chalk on the bottom).

- The nut version of the fittings will require open-end wrenches 17, 19.

- For latches, the help of pliers is sufficient. Sequentially, right, left, disconnect the tubes.

- Use 10mm wrenches to unscrew the bolted connection, loosen the clamp, and carefully pull the filter to the right.

Third step

- Install and secure the VAZ 2114 fuel filter (check the alignment with the arrow).

- Screw the spool back in.

- Connect the battery.

- Remove rags soaked in gasoline to avoid the possibility of ignition.

- Turn the ignition key. The operating logic of the control unit provides for filling the fuel system before starting and creating pressure. The fuel pump relay is activated briefly.

- A new, dry filter is impregnated.

- Turn off the ignition.

- Repeat the procedure with a time interval several times.

- Check the tightness of the connections of the pipes.

- Tighten the fasteners (if necessary).

- Start the engine.

- Operate the gas pedal.

No dips, stable idle speed - replacing the gasoline filter on a VAZ 2114 was completed successfully. Make a test drive, test different engine modes. Make the necessary adjustments.

Access to the fuel pump and its dismantling

Before starting work, to eliminate the risk of a vapor explosion and a fire, you must first de-energize the vehicle by removing the negative terminal from the battery. Gasoline is completely drained from the tank. It is necessary to work with open doors to minimize the risk of poisoning by gasoline vapors.

To access the VAZ 2114 fuel unit module, you must completely remove or tilt forward the rear seat cushion, under which there is a square-shaped hatch on the bottom of the body that covers the fuel pump. The hatch cover is secured with two bolts and closes the unit itself.

The unit is dismantled with the electrical wires disconnected, then using two 17mm wrenches, the two fuel pipelines are removed and the eight fastening nuts are unscrewed with a 10mm wrench. After this, the fuel pump can be removed from the fuel tank.

When removing the pump from the tank and installing it in a standard workplace, care should be taken due to the low mechanical strength of the individual components of this unit.