Reasons for tripping of diesel internal combustion engines

It is somewhat easier to answer the question of why a diesel engine is tripping, to determine the causes and to localize the fault compared to gasoline units. A diesel engine often “troubles” for two main reasons: lack of proper compression of the mixture or problems with fuel supply.

It is more difficult to determine the cause if all cylinders are working, but the diesel engine still vibrates and operates erratically. The cause may also be air leaks, problems with sensors, ECU, etc. It is often difficult to quickly find such a malfunction.

The main difference in the operation of a diesel engine is the method of ignition of the fuel-air mixture. Diesel fuel is ignited in the cylinder due to compression. In other words, diesel fuel spontaneously ignites. Additionally, it is necessary to take into account the moment when the “triple motion” of a diesel engine increases. A diesel engine can bleed cold, hot, idling and/or under load. The problem may appear only in a specific narrow speed range, occur periodically, or be present constantly.

Ignition

The car is tripping the injector due to the module

Article on the topic: Installing fog lights on a car

The ignition module is a unit that comes into question after all the checks have been carried out. It is the bobbin that can become the culprit for the power unit tripping at idle or in other modes. To check the coil you need to do this:

- Unscrew the spark plug, then apply it to the ground (any part of the body).

If the spark is good, its color is of high quality, and a characteristic crackling sound is heard, then the serviceability of the reel is not questioned. On the contrary, if there is no spark, or it is of poor quality, the module must be replaced, and thus it will be possible to “cure” the tripping.

It's not very often that a switch goes bad, but it does happen. It must be checked and, if anything, replaced.

Diesel fuel does not ignite: compression is lost

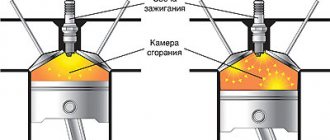

Ignition of the fuel-air mixture of a gasoline and diesel engine

The cylinder-piston group of any internal combustion engine experiences increased loads. During operation, the gaps between the parts of the CPG increase as the elements wear out. The valves of the gas distribution mechanism are also subject to wear.

The loss of the ability to ensure tightness when one of these parts is destroyed leads to the fact that proper heating of the mixture is not ensured during the compression stroke. Diesel fuel simply cannot ignite.

If the compression ratio is insufficient (loss of compression), the diesel engine throttles strongly after a cold start. As a result of heating, the CPG parts expand and the seal in the cylinder increases. A heated diesel engine shakes noticeably less, and the tripping effect may disappear completely. This phenomenon is observed only if there is no critical wear of the CPG or valve mechanism elements.

It turns out that the wear of the cylinder-piston group with engine heating is partially compensated due to the fact that the diesel fuel in the cylinders self-ignites due to an increase in the temperature of the internal combustion engine. There is a situation where a diesel engine misfires after replacing the cylinder head gasket with a new one. In this case, the working unit with a worn-out CPG throttles strongly “on cold” and adjusts “on hot”.

This malfunction is explained by the fact that the new gasket is thicker than the old one. The result is a lower compression ratio, further exacerbating existing compression problems. A thicker gasket affects the efficiency of self-ignition of the working mixture of diesel fuel and air in such an engine.

What happens if the problem is not fixed?

Since this phenomenon occurs when it is cold, and when it warms up the problem is no longer noticeable. Therefore, many drivers, not wanting to spend money on repairs, simply do not pay attention, believing that the problem is not serious.

Motor performance

when tripling they decrease. Compression begins to drop, engine speeds fluctuate, fuel consumption increases, acceleration dynamics are weak, wear on the piston rings increases, and the inner walls of the cylinder begin to be damaged. May be needed.

Ultimately, without making timely repairs, thinking to save money, you will spend much more money on major repairs or on replacing the power unit.

Before correcting malfunctions, you need to conduct diagnostics and determine the cause of the tripping. If the problem is with the spark plugs or wires, replacement can work around the problem.

If the fuel or air filters are clogged, this will cause the owner a lot of problems. Dirty injectors are washed with the intended product, and if necessary, replace the lambda probe.

If after cleaning the injectors nothing has changed, then they need to be replaced. Also, with all elements of the fuel system that cause problems with tripping, replacement will be the best solution as opposed to repair. It is also worth replacing all air supply parts. The last step will be to correct errors in the electronic control unit that cause the engine to stall when cold.

Instructions

Listen to the engine while driving and remember what the sound was like before. Notice if the engine begins to run unevenly, if the speed fluctuates. Try to accelerate and determine whether the car is the same as before, whether it has power. If you feel some of these signs in your car, consider a thorough technical inspection and repair, most likely the engine.

Stand near the exhaust pipe and listen to the sound of the engine. If you hear a uniformly audible “boo-boo-boo” characteristic of a “tribling” engine, do not rush to conclusions, since the cause of poor performance may simply be freezing of the working parts. Warm up the engine for a while and listen again. If the sound has not changed, it means .

Try this method. While driving, press the accelerator pedal sharply and accelerate. Listen: if the engine did not react immediately, but first “boomed” (the sound of “boo-boo-boo-boo-boo-boo-boo-boo”), most likely there is something wrong with one of the cylinders, that is, the engine is misfiring.

Start it. Try to feel the engine idling: if it is uneven, with “dips,” then most likely there are problems with one of the cylinders. The reasons may be different, including engine tripping; carry out a full diagnosis and think about repairs.

Start the car and open the hood. Remove the spark plug caps one by one, thereby disconnecting the spark plugs from the engine. Listen carefully to the sound of the engine, if the sound has changed, then everything is in order with this spark plug, and if the sound has not changed, then the problem is with this spark plug.

If you still doubt whether the engine is running, contact an experienced driver or a service station. Please note that this breakdown is very serious and requires a thorough investigation of the causes and immediate repair.

note

Driving a car whose engine runs on three out of four cylinders is dangerous for both the car and the driver, since the engine simply begins to wear out and overheat catastrophically quickly. However, you will be able to get to the car service center (if it is not 1000 kilometers away).

Unstable engine operation (motor “troits”) sharply reduces its power and increases fuel consumption. All that can be done in such a situation is to slowly get to the garage and begin to find out the reasons for the “incorrect” operation of the car.

The reason for the “triple” of the engine is the inoperability of one of the cylinders. To find out the causes of the malfunction, you can first conduct independent diagnostics. Sometimes it is possible to find the cause and eliminate it within just a few minutes. But there is another situation when a major overhaul is necessary to restore normal operation of the engine. Why doesn't the cylinder work?

Diesel misfires due to glow plugs

Glow plugs play an important role in a diesel engine. For a confident start “on cold”, the glow plugs heat the combustion chamber. This is necessary so that self-ignition of the mixture of air and diesel fuel occurs easily during startup. Next, the glow plug continues to maintain the set temperature in the cylinder until the engine finally reaches operating temperature. After this, the candles automatically turn off.

After contact with the candles, diesel fuel scatters into tiny particles, partially evaporates, and mixes better with the air. As a result, the resulting mixture burns as efficiently as possible, transferring energy to the piston. If the glow plug is faulty, the temperature in the cylinder during a cold start will be too low and the diesel fuel will not be able to self-ignite.

The cylinder will be inoperative, although it will receive fuel, which then enters the exhaust system of the diesel engine. In this case, the diesel engine often produces dark gray or black exhaust. As the temperature of the internal combustion engine increases, the fuel (taking into account normal compression) will begin to ignite, but intermittently. The problem will go away completely after warming up, but with a subsequent cold start the malfunction will recur.

Unstable operation of a diesel engine after partial warming up (provided that the diesel engine worked normally during a cold start) can be explained by the fact that no electric current is supplied to the glow plug in the mode of further maintaining the required temperature in the cylinder. The heating element of the candle (rod) will remain cold, diesel fuel will fall on it, but the quality of the atomization will noticeably decrease. Under such conditions, the mixture formation in the chamber is disrupted, the fuel does not burn completely, the diesel engine smokes and runs hot. In such cases, the glow plugs must be replaced immediately.

Diesel shakes and smokes: problems with fuel supply

If there are problems with the fuel supply, then the diesel engine starts to stall for the following reasons:

- the fuel pump does not create optimal pressure in the fuel supply system;

- the injection intensity is disrupted as a result of a malfunction of the diesel injector;

In both cases, fuel atomization deteriorates and the mixture does not burn completely. The fuel injection pump can create normal pressure, but the fuel injectors deliver different amounts of fuel to the cylinders. In such conditions, fuel is distributed unevenly among the cylinders, the engine shakes in different operating modes. If it is completely impossible to pump a portion of diesel fuel through the nozzle, the diesel engine begins to stall. Cleaning, repairing, or replacing injectors must be accompanied by adjustment of the injectors before installation on the engine.

At the same time, it is necessary to regulate the fuel injection pump. The pump may be worn out and/or incorrectly adjusted, resulting in insufficient pressure to deliver the required amount of diesel fuel through the rebuilt or replaced injectors. The diesel engine may start to run rough, with detonation. Replacing injectors is necessarily accompanied by checking the performance of the fuel injection pump.

If there are problems with both the fuel pump and the injectors, the parts must be adjusted, repaired or replaced immediately. Detonation on a diesel engine will quickly damage the engine.

Treatment of engine throbbing and backfire by replacing the injector.

The situation was clear. It was necessary to start replacing the Sang Yong Chiron diesel injector

.

At the same time, I had to change the glow plugs, having found a new set in the warehouse. Why is this necessary? Because you cannot put one new candle and leave the rest as old. The balance in the operation of the gas distribution mechanism in the engine will again begin to be disrupted. Complete replacement of Sang Yong injectors

in the kit managed to avoid. The original injectors from other cylinders were thoroughly cleaned in an ultrasonic bath to a new condition. Instead of the collective farm injector on the third cylinder, we installed a factory injector identical to the other three. After these manipulations, the engine stopped stalling and started running evenly. Computer diagnostics showed that the error in engine operation had gone away. Here's your grandmother, and St. George's Day. Without much hassle and without expensive motor replacement. Why couldn’t this be done through resellers? There was no time to figure it out, the main thing was to push the car away as quickly as possible.