Maintenance of the ignition system of the GAZ-53-12 car

Spark plugs A11

car GAZ-53-12

It is recommended to use A11 spark plugs for the engine (Fig. 197).

Maintenance of spark plugs consists of checking their condition, cleaning them from carbon deposits and adjusting the gap between the electrodes. It is necessary to regularly wipe the spark plug insulators. Periodically remove the spark plugs to inspect and adjust the spark gap. Before removing the spark plug, be sure to remove dirt from the spark plug seat in the cylinder head with a brush or compressed air.

Spark plugs should be checked after running the engine under load. Running the engine at idle also changes the nature of the deposit, which can lead to incorrect conclusions.

about the work of the candle. The spark plugs should only be removed with a special (spark plug) socket wrench provided in the driver's tool kit.

When inspecting a spark plug, you must especially carefully check for cracks on the insulator, pay attention to the nature of the carbon deposits, as well as the condition of the electrodes and the gap between them. The conical part of the spark plug insulator (skirt) should not have carbon deposits or cracks. Spark plugs with cracked insulators must be replaced.

It must be remembered that when candles work, a reddish-brown coating usually forms on their skirts, which does not interfere with the work of the candles. This deposit should not be mixed with carbon deposits; such candles do not need cleaning.

Rice. 197. Spark plug with anti-interference tip: 1 - tip body; 2—output; 3—spring; 4 - resistor; 5 - tap; 6 — contact device; 7 — fixing spring; 8 - spark plug insulator; 9 — spark plug body; 10 - side electrode; 11 - central electrode

Candles with carbon deposits must be thoroughly cleaned using a special sandblasting machine E203.

When cleaning the insulator, it is not recommended to use sharp steel tools, as this will create scratches and irregularities on its surface, which will further contribute to the deposition of carbon deposits. If it is impossible to clean the spark plugs and the carbon layer is large, then the spark plugs should be replaced.

After cleaning, it is necessary to check the gap between the electrodes using a round wire feeler gauge (Fig. 198).

Rice. 198. Checking the gap between the spark plug electrodes

Fig. 199. Adjusting the spark gap in the spark plug

Adjustment of the gap between the electrodes should be done by bending the side electrode (Fig. 199). The gap between the electrodes should be 0.8 - 0.95 mm.

It is recommended that spark plugs, cleaned of carbon deposits and with an adjusted gap between the electrodes, be tested on a spark plug pressure tester before installation on the engine. In serviceable spark plugs at a pressure of 800 - 900 kPa, a spark should appear regularly, without interruptions between the central and side electrodes and without a surface discharge. At a pressure of 1000 kPa, a new non-working spark plug must be completely sealed: it must not allow air to pass through either the connection between the housing and the insulator, or through the connection between the central electrode and the insulator. For spark plugs running on an engine, an air flow rate of up to 40 cm3/min is allowed.

The spark plug must be installed in place with a gasket. Screw in the spark plug first by hand and then tighten it with a spark plug wrench. The gasket is not a solid washer, but is rolled up from thin metal and is designed to collapse when tightened, so you should not use excessive force when installing the spark plug. It is necessary to tighten it so that the gasket is not completely flattened. It is recommended to replace a completely flattened gasket the next time the spark plugs are removed. When the wire is disconnected from a normally working spark plug, the engine speed decreases, and when the wire is disconnected from a damaged spark plug, the speed remains unchanged. Spark plugs that do not work or work with great interruptions are colder to the touch than the others, therefore, they can sometimes be detected by this sign. Malfunctioning spark plugs is one of the causes of oil dilution in the engine crankcase. If liquefied oil is detected, it must be changed, and the spark plugs must be checked and any that are not working must be replaced.

High voltage wires.

High voltage wires are made of PVVP or PVPPV wire. These wires have a core with ferrite filler, on which a spiral of wire with high ohmic resistance (2000±200) Ohm is wound per 1 m length. Distributed resistance wires reduce the level of radio interference generated by the ignition system.

Why do spark plugs break when pressure increases?

This is a part of an internal combustion engine, screwed into the head of the block, designed to ignite the air-fuel mixture through a high-voltage electrical discharge.

Many people know this. Yes, there are different (in size, heat rating and other characteristics) candles - but let’s not talk about that. However, not everyone knows that spark plugs begin to work unstably (due to their breakdown) when the pressure in the combustion chamber increases. This is when, when voltage is applied to the spark plug, the spark turns out to be unstable, weak, or even completely absent. The question arises - why? This is what we will talk about in this article.

So, for example, there is a candle. We check it “for a spark” (i.e., unscrew it from the engine, connect it to a high-voltage wire and short the housing to ground; in this case, the air pressure in which the spark plug electrodes are located is equal to atmospheric pressure, i.e. the pressure is low) - it seems, Everything is fine.

The spark is quite powerful and a characteristic crackling sound is heard. But, being screwed into its working place, it sometimes does not work as expected, as a result of which the engine begins to “triple” (i.e. misfires occur, which leads to a decrease in the maximum engine power, as well as to excessive fuel consumption).

It is clear that it will be better if in this case you replace the spark plug with a new one. But, by the way, why waste time on trifles: you can immediately replace the car with a new one, acting on the principle set out in something like this joke: The owner of a car comes to the car dealership, who bought it a week ago and demands: - take it back; I don’t need money for it, just take it so that it’s gone, and I’ll buy the same new one from you. - so, what’s the matter, maybe it can be repaired. - Yes, nothing is needed, I don’t want to see him anymore, take him, I tell you; I don't demand money back. - well, but still, you can at least ask - why don’t you like him? - Well, you give it! Well, okay, look into the cabin: you see, there is an ashtray full of cigarette butts. How am I going to ride it?! But it is still of interest, what causes the spark plug to malfunction when it is performing its function and not just being checked?

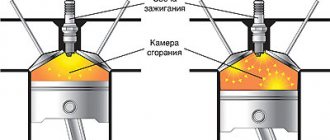

The main reason is that in the combustion chamber the fuel-air mixture is compressed before ignition, and quite strongly, especially in diesel engines (the pressure there can reach 16...20 atmospheres or even more). In gasoline internal combustion engines, the pressure (compression) is lower and, for a working engine, is 12…15 atmospheres.

So, when the pressure increases (i.e. when the spark plug is not at atmospheric pressure, but in the combustion chamber of the engine), the spark plugs begin to “break through”. This is expressed in a weakening, or even complete disappearance of the spark between the electrodes of the spark plug. Question: what happens, is there really no electrical discharge occurring? After all, high voltage is supplied.

The weakening or disappearance of the discharge between the electrodes of the spark plug is due to the fact that with increasing pressure, the breakdown voltage of the gas (including the fuel-air mixture) increases. Consider, for example, the curves in Figure 3.8. 3.15 from the Handbook of Electrical Materials (Authors: Yu.V. Koritsky, B.M. Tareev, V.V. Pasynkov), page 52. 54. We see that, for example, for air, nitrogen, SF6 gas in the pressure range 0 ,1. 1.0 MPa (1.10 atm or kgf/cm2), in general, there is a proportional relationship between gas pressure and its breakdown voltage. Similar curves exist for fuel-air mixtures. We think they can be easily found in relevant reference books, scientific articles, diploma or dissertation works on the relevant topic.

This means that the higher the gas pressure, the higher, as a rule, its breakdown voltage (although this is up to certain limits). Those. the more difficult it is for an electric spark to form on the spark plug electrodes. That is why, by the way, competent car service workers, when diagnosing the operation of a car engine, check the spark plugs on a special stand, in some kind of simulating the conditions in which the spark plug operates in the engine: the imitation consists of feeding fuel into the chamber where the spark plug is located. increased air pressure (using, for example, a hand pump. Yes, exactly a hand pump, because the air from the compressor often contains a lot of water vapor, which distorts the process of diagnosing spark plugs) and then gives an electrical voltage. So, there are often cases when spark plugs operate quite stably at, say, 4.6 atmospheres, but begin to experience interruptions in sparking at higher pressures.

The fact is that in this case the electric discharge no longer occurs by breaking down the gap between the electrodes of the spark plug, but either through its insulator, or (more often) along the surface.

Yes, on the one hand, judging by Figures 3.19, 3.23, 3.25 (pages 54. 57) of the mentioned reference book, the flashover voltage (i.e., the discharge in a gas along the surface of a dielectric, for example, a porcelain insulator of a spark plug) is the same as the voltage breakdown of the gas gap increases with increasing gas pressure (fuel-air mixture). But, on the other hand, this voltage can be significantly reduced when the surface of the spark plug insulator (meaning the part that is located in the combustion chamber) is contaminated with fuel combustion products, in particular carbon, which is known to be a good conductor of electric current . In addition, a kind of fatigue of the porcelain insulator takes its toll. Both on the surface and inside of which areas with reduced electrical resistance begin to appear, and in greater and greater numbers (approximately as in the figure).

GAZ 52-03 2 doors. onboard, 75 hp, manual transmission, 1958 – 1988 — the engine troits

content .. 936 937 938 ..The main reasons for tripling

— The ignition timing is incorrectly set. — There is an air leak in the vacuum brake booster system. — Faulty spark plugs. It is worth noting that this problem is the most common, since spark plugs need to be changed after driving a car every 20,000 kilometers (this figure depends on the recommendations given by the designers of each car). — Breakdown of the high-voltage wire that goes to the spark plug. — Faulty installed capacitor. — Violation of the tightness of the system in the area of the intake manifold. — Burnout of one of the piston or valve. — Breakage of piston rings, their deformation and wear also lead to this problem. — Incorrect adjustment of the gas distribution valves. — High degree of rocker wear. — Breakdown of the installed cylinder head gasket. — Any type of wear (hardening, breakdown, destruction) of the valve stem seals. — If the carburetor is adjusted incorrectly, the cylinders may also malfunction. — Condition of the installed distributor shaft and rotary plate bearing. — Air filter clogged. — Loss of tightness of the membrane of the vacuum ignition timing regulator. — Use of unsuitable spark plugs (not only the dimensions, but also other parameters of this element are taken into account) for this engine.

Engine troubles

Engine tripping is a definition that should be understood as a malfunction of the internal combustion engine when one or more cylinders do not work partially or completely. To put it another way, the combustion process of the fuel-air mixture in individual cylinders is disrupted, which causes unstable operation of the engine at idle, under load and in transient modes.

Engine trouble manifests itself in the form of increased vibrations of the power unit, and the engine noticeably loses power. Misfires may occur, which are accompanied by strong pops in the exhaust system. The engine can stall either occasionally or constantly, only at idle or under load, cold, hot, etc. Next, we intend to answer the question of what engine tripping is, and also consider the main reasons why the engine begins to trip.

Why does the engine start to stall?

Engine tripping is a violation of the combustion of the mixture in the cylinders, which is accompanied by a clear increase in vibration. Please note that the appearance of internal combustion engine vibrations is not necessarily a tripping, since there are a number of other reasons why the engine vibrates strongly. The list of main faults that cause the engine to stall includes:

supply of insufficient or excess fuel to the cylinder; supply of insufficient or excess air; malfunction of the ignition system, early or late ignition; wear or breakdown of the motor, which is accompanied by a decrease in compression; In other words, the engine begins to stall as a result of an inappropriate composition of the fuel-air mixture, untimely ignition of the mixture or inability to ignite the charge, as well as violation of the conditions for normal combustion of the mixture as a result of mechanical wear or breakdown of the engine itself. Based on this data, you can narrow your search and the number of systems for diagnosis. The check should begin with the fuel system and injector, then the intake air supply and the ignition system are checked. In some cases, engine stalling may also be the result of a failure of one of the ECM sensors.

Engine troubles: ignition of fuel-air mixture is disrupted

The most common reason that causes the engine to misfire is late or early ignition, as well as a weak spark plug. At the initial stage, you should unscrew the spark plugs for a detailed inspection. If damage to the insulator or other defects is noticeable, then the spark plug should be replaced.

In the case of a damaged insulator, the place of damage is clearly visible, since this area turns black. You should also pay attention to the condition of the central electrode and evaluate the gap of the side electrode. Next you need to check the spark plug wires. An indirect sign indicating this element is the occasional tripping of the engine in conditions of high humidity (rain, dampness, etc.). After the engine warms up and reaches operating temperature, the symptoms may disappear completely.

You should start by inspecting the spark plug cap and the highest voltage wire. These elements have rubber insulation, which tends to dry out and crack over time, as a result of which the wire begins to break through. Also, the high-voltage wire or cap is often damaged during service or repair work in the engine compartment. Let us add that the location of the breakdown may not be visually detectable. In this case, it is better to check this element of the ignition system using one of the available methods. If everything is in order with the spark plugs and wires, then the ignition coil may be the culprit for the engine misfiring. On engines with separate coils for each spark plug, this phenomenon is especially widespread. To check the ignition coil, you need to unscrew the spark plug, apply it to ground and start the engine. Please note that the thread of the candle must tightly touch the mass, the cap must be tightly placed on the candle. Ignoring these rules may result in burnout of the coil or commutator. A good spark with a characteristic crackling sound will indicate the serviceability of the coil; the absence of a spark will indicate the need to replace the coil.

As for the electronic ignition distributor (switch), this element does not break down often. To check, the spark plugs are securely attached to ground, then the caps are connected to them, after which one person turns the engine with the starter, and the other evaluates the strength of the spark on the spark plugs.

Motor tripping: air supply problems

Inadequate or excessive intake air can also cause cylinder misfire. The air supply system may lose its tightness and the engine begins to suck in excess air. The ECU does not take this leak into account, and as a result, the stability of operation is disrupted.

Checking the air system is quite simple. It is necessary to tightly close the inlet pipe next to the air filter, then pump air to create a pressure of about ½ atmosphere, and then look for the leak. If the pressure does not drop, then the system is sealed. The appearance of a hissing sound of escaping air allows you to determine the problem area through which the motor is sucking in excess.

Lack of air often occurs due to a dirty air filter that has lost its capacity. The filter must be removed and the engine performance assessed after removal. There may also be insufficient air if the throttle valve is clogged or there is a problem with this unit. This element requires mandatory cleaning and inspection. It is advisable to do this at every scheduled maintenance in parallel with replacing engine oil, filters, etc. Another reason for the engine tripping may be the TPS, mass air flow sensor or another sensor that sends an incorrect signal to the ECU. In such a situation, the control unit does not know to what degree the damper is actually open, how much air actually entered the engine, etc. Based on incorrect data, the “brains” cannot accurately calculate the optimal composition of the fuel-air mixture in relation to the dynamically changing operating modes of the internal combustion engine.

In this case, you should view the sensor readings and read the errors using a scanner that is connected to the vehicle’s diagnostic connector. Then the values must be compared with the nominal ones. Deviations from the norm in the readings of the air flow meter or throttle position sensor lead to the engine starting to stall.

Troubleshooting in cylinders: faulty power system

When checking the power system, you should pay attention to the following nuances:

fuel pressure; air leak; Fuel pressure directly depends on the serviceability of the electric fuel pump, which on modern injection cars is located in the fuel tank. The device may have a clogged fuel pump filter, or problems may arise with the electric motor of the fuel pump or the power supply to the pump. It is also worth checking the pressure regulator valve in the fuel rail. Low pressure in the fuel supply system is often the cause of tripping.

The next step is to check the injection nozzles. This element tends to become clogged, resulting in reduced throughput, disruption of the spray pattern, etc. Also, failure of the injector itself should not be ruled out. To clean and check the injectors, you can use a washing stand, in which a special washing liquid is pumped through the device and power is supplied. Under such conditions, the operation of an injector on an engine is simulated, performance is assessed, etc.

You can also check and clean the injectors yourself. To do this, liquid (for example, carburetor cleaner) is also pumped through the device. Power is supplied through a simple circuit with a light bulb from the battery terminal. A working injector should not leak when closed. Also, the injector must open in a timely manner when an electrical impulse is applied. It is not allowed for the injector to pour fuel, since the efficiency of subsequent combustion of the charge in the cylinder depends on the quality of the spray.

If the fuel pressure and the injector itself are OK, then you should check the ECU. The control unit itself rarely fails, but it is possible. More often this happens in cases where the factory firmware was changed when installing an LPG or the engine was given software chip tuning. Unprofessional manipulations with fuel maps can lead to the ECU overfilling the fuel and flooding the spark plugs.

Reduced compression in cylinders

A drop in compression indicates engine failure or wear. One or more cylinders are partially or completely inoperative, so fuel and air are delivered, but the mixture is not compressed properly. In this case, normal combustion does not occur. A drop in compression occurs due to burnout of pistons or valves, severe wear of piston rings and other defects in the cylinder head, cylinder head or timing elements.

In this case, it is necessary to measure the compression in the engine, after which the unit is disassembled for detailed diagnostics and repairs. In conclusion, I would like to add that operating an engine with a malfunctioning cylinder is prohibited, since driving with such a malfunction leads to a number of additional problems, which significantly complicates and makes subsequent repairs more expensive.

Specifications

Technical characteristics of GAZ 52-03 in a 2-door body. onboard with 75 hp engine, manual transmission, produced from 1958 to 1988.

Basic data

- Start of production:

June 1966 - End of production:

January 1975

- Body:

2 doors onboard

Engine

- Engine capacity, cubic meters see: 3485

- Power, hp: 75

- Achieved at vol. per minute: 2900

- Maximum speed, km/h: 70

- Cylinder diameter, mm: 82

- Piston stroke, mm: 110

Transmission

- Transmission: Manual

Dimensions

- Length, mm: 6395

- Width, mm: 2280

- Height, mm: 2190

- Wheelbase, mm: 3700

- Ground clearance, mm: 245

Other

- Curb weight, kg: 2815

- Fuel tank volume, l: 90

content .. 936 937 938 ..

Halo on the spark plug insulator

As for the dark rim (halo) on the outer surface of the spark plug insulator, it, as a rule, is not at all associated with cracks on it, with “penetration of gases from the combustion chamber,” as you can sometimes read on automobile forums. Some “experts” even advise changing the spark plugs as soon as such a rim appears. It’s funny, but this is being discussed with might and main, in all seriousness, by “experts.” Which then “promote” their clients to replace spark plugs, and also create the impression of their qualifications.

In fact, the reason for the appearance of a halo is banal. During the operation of the spark plug, its outer part (insulator) is electrified, i.e. electric charges appear on it, and of high magnitude. This leads to the fact that particles of dust, oil, etc. located in the engine compartment, being ionized, are in turn attracted to the insulator. And, since the latter heats up quite strongly when the engine is running, they stick and remain there in a solid coke-like state. By the way, a similar effect is used in the electropurification of gases. So there is nothing so paradoxical here.

And so that the resulting halo, due to its lower electrical resistance compared to porcelain insulator, does not interfere (by shunting the electric spark gap between the electrodes of the spark plug) with the spark formation process, a special cap (usually black) is put on the spark plug, covering a sufficient the length of the insulator where a halo will not form. Therefore, the presence of a halo practically does not interfere with the normal operation of the spark plug (which, by the way, is also reported by spark plug manufacturers), indicating, perhaps, its age and/or its intensive use. And also that oil vapors, dust particles or something else get into the engine compartment.

Messages 11

#1 Theme from Sante>

- Santa>

- Jedi Knight

- From: Maternity hospital

- Registration: 11-06-2007

- Messages: 4,019

Topic: Filling spark plugs Gas 53

troits, traction disappears. We turn it around and check the spark plugs - are the spark plugs sooted and wet from gasoline that they are shit or should the carb be adjusted? It's probably not a matter of GDP and the power of the spark from the coil. We install new ones from the packaging - after a while the car is often used again for slow driving in 1st gear at idle BSZ Which brand of spark plugs will be the best for it?

#2 Reply from Antei 07/02/2016 12:16:11

- Antei

- Jedi Knight

- Registration: 03-06-2011

- Messages: 1,191

Re: Filling spark plugs with Gas 53

It's most likely not the candles. The needle in the carburetor is stuck or the accelerator pump is not working. Unless, of course, you climbed into the carburetor yourself and mixed up the jets.

#3 Reply from family man 07/02/2016 12:18:01

- family man

- Blocked

- From: Magovo village

- Registration: 02-12-2015

- Messages: 8,687

Re: Filling spark plugs with Gas 53

IGNITION WHEN FILLING spark plugs has nothing to do with it

#4 Reply from Sante>

- Santa>

- Jedi Knight

- From: Maternity hospital

- Registration: 11-06-2007

- Messages: 4,019

Re: Filling spark plugs with Gas 53

We tried different spark plugs with heat ratings of 14 and 17, it seems like 11 is needed, are they still being produced?

#5 Reply from Antei 07/02/2016 12:24:19

- Antei

- Jedi Knight

- Registration: 03-06-2011

- Messages: 1,191

Re: Filling spark plugs with Gas 53

We tried different spark plugs with heat ratings of 14 and 17, it seems like 11 is needed, are they still being produced?

heh. They tell you that candles have nothing to do with it. Tell me, what were you guided by when changing spark plugs with different heat ratings?? And in general, if we’re going to go into things like heat rating, then tell us what it is, enlighten us.

#6 Reply from Sante>

- Santa>

- Jedi Knight

- From: Maternity hospital

- Registration: 11-06-2007

- Messages: 4,019

Re: Filling spark plugs with Gas 53

photo from the Internet: this is what the candles look like

And in general, if we’re going to go into things like heat rating, then tell us what it is, enlighten us.

ability of candles to self-clean from carbon deposits?

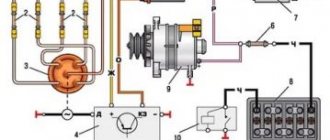

Design of the GAZ 53 ignition system

The GAZ-53 is equipped with a non-contact transistor ignition system, the primary circuit of which produces a voltage of 12 volts. The ignition system is considered battery-based, consisting of sources of electric current, which can be a battery, ignition coil, switch, sensor-distributor, and other electrical equipment gas 53, which most often causes problems, since it needs to be adjusted, spark plugs with tips, additional resistor, ignition switch, low and high voltage wires.

The drawing shows a complete diagram of the GAZ-53 ignition system

The ignition system is one of the most important systems in a car, since the operation of the engine, as well as the fuel consumption of the entire car, depends on its proper operation. To suppress radio interference created by high voltage wires and spark plug tips, distributed resistance is installed on the former, and suppression resistors are installed on the latter.

The ignition system contains a B 116 brand coil, the purpose of which is to convert low voltage current to high voltage.

In turn, the coil consists of a transformer in which an iron core is mounted. The primary winding is wound on top of this core, and the secondary winding is below it. The transformer itself is a steel case, which is hermetically sealed; oil is poured inside it along with the core.

To maintain this transformer, a plastic cover is provided that can withstand high voltage.

The first GAZ 53 trucks had a contact-transistor ignition system, then it became contactless electronic. Since the contact (or contact-transistor) system is already hopelessly outdated, we will consider a contactless system. The GAZ 53 ignition system consists of a low-voltage and high-voltage circuit. The low voltage circuit includes:

- Accumulator battery. In the battery, six 2-volt banks are connected in parallel to each other, for a total of 12 volts. The GAZ 53 is equipped with a 6ST-75 battery with a capacity of 75 a/h as standard.

- Battery wires with terminals. The wires are multi-core and have a large cross-section.

- Egnition lock. Serves to supply power to the low-voltage circuit.

In the extreme left position (clockwise), the contacts on the starter solenoid relay are closed, and the engine is driven by the starter.

- Breaker. In GAZ 53 it is located in the distributor. In contact ignition, the role of the breaker was performed by the cam shaft of the distributor and the ignition contacts; in a more modern version, the role of the breaker is performed by the Hall sensor.

- Switch. Ensures stable operation of the breaker.

- Variator (resistance). Provides stable engine starting and relieves the work of the ignition coil at high engine speeds. Due to the variator, the coil does not overheat. On more modern versions of the system, the variator was removed (in the gas 3307 model), and the role of the variator began to be played by an additional transistor located in the circuit of the new switch.

- Primary winding of the ignition coil (SC). It has a small number of turns and relatively thick copper wire.

Checking the ignition coil with a multimeter

The secondary (high-voltage) circuit contains the following elements:

- Secondary winding short circuit. It has a large number of turns and thin copper wire.

- Ignition distributor GAZ 53. The distribution part of the distributor consists of a shaft, a distributor cap and a slider.

- High voltage wires and lugs. Through them, a high-voltage pulse is supplied to the spark plugs.

- Spark plug.

The main reasons causing the formation of soot

To understand why the candles are black, you should first understand the nature of the blackening itself. For example, blackening may be present along the entire circumference or only on one side; there may be carbon deposits on one or two candles or the entire set. In addition, plaque can be dry or wet. By determining the characteristics of soot, it will be possible to understand what exactly led to its occurrence.

The formation of carbon deposits usually begins to become noticeable on new spark plugs if there is a problem after 200-300 kilometers.

In order to most accurately determine the malfunction, it is advisable to maintain approximately the same speed limit while driving and not overload the engine. In this case, the work of the candles will be optimal, and the results obtained will be as reliable as possible.

The amount and type of carbon deposits are directly affected by the quality of the fuel the vehicle runs on. In this regard, you should only refuel at proven gas stations that offer high-quality fuel. Otherwise, identifying the real cause of soot formation will be extremely problematic.

On a car equipped with a carburetor-type power unit, it is important to set the idle speed correctly so that the fault can be reliably determined by the resulting carbon deposits.

The most typical causes of black carbon deposits on spark plugs are:

- Burnout of the valve, which manifests itself as blackening on one side. Carbon deposits fall onto the side electrode from below.

- Incorrectly selected heat value of the candle, due to which in the future it will simply cease to function, and at first it will turn black unevenly. If the number is small, the shape of the soot cone will change; if it is too large, the body will remain white, and only the top of the cone will turn black.

The heat number is a value that characterizes the time period during which the candle achieves glow ignition. In the case of a high number, the heating of the candle occurs less. Only install parts that have the same heat rating as recommended by the machine manufacturer.

- Late ignition, the consequence of which is the formation of a uniform black coating.

- Excessively enriched fuel-air mixture produced by an injector or carburetor (depending on engine type).

In the case of an injection engine, the problem often lies in the incorrect operation of the mass air flow sensor, from which the electronic on-board unit receives data regarding the composition of the mixture. Sometimes the appearance of carbon deposits is caused by the loss of tightness of the fuel injectors, and even if they are closed, fuel gets into the cylinders.

In carburetor-type power units, the cause may be an incorrectly adjusted fuel level in the carburetor, loss of tightness by the needle gap valve, creation of excess pressure by the fuel pump, lack of tightness of the float or its contact with the chamber walls during operation.

- Excessive wear or loss of tightness of the power mode economizer ball valve on power units with carburetors. Under such conditions, the engine in normal modes receives a volume of fuel designed for power modes.

- If the spark plugs are sooty, the reason may lie in simple contamination of the air filter. Therefore, it is imperative to inspect it and, if it is clogged, replace it. It is also worth checking that the air damper actuator is operating correctly.

- Problems in the ignition system, for example, incorrectly adjusted ignition angle, damage to the insulating layer of high-voltage wires, damage to the slider or distributor cap, problems with the ignition coil or the spark plugs themselves. Factors of this kind can lead to instability or weak sparking, as a result of which not the entire volume of fuel burns and black carbon deposits form.

- Problems with the engine valve mechanism, for example, poorly adjusted valve clearances or burnout. Due to such problems, the air-fuel mixture does not burn completely, and carbon deposits form on the spark plugs.

- Failure of the fuel regulator on cars with an injection engine and the formation of excess pressure in the fuel rail.

- Low level of compression in the cylinder.