Why a maintenance-free battery may need to be serviced

In maintenance-free batteries, there is almost no evaporation of water due to the fact that during charging, the boiling electrolyte inside the cans condenses back into liquid through the labyrinth lid.

Moreover, if for some reason you violate the operating rules (charging with high currents, using a faulty generator, etc.), then a lot of steam will accumulate in the tanks, which will be released through pressure relief valves to avoid the explosion of the housing.

Labyrinth lid design

Note! The only reason maintenance may be required is if the liquid from the cans evaporates. If this happens, then any battery can be made serviceable.

Modern batteries can be used for more than 5 years with virtually no reduction in performance, but cheap, maintenance-free models are not always able to last even half of this period. To extend the period of effective use of such batteries, many car owners are trying to make the product serviceable.

Experienced motorists, knowing in advance that cheap, well-maintained batteries will not last long, immediately after purchase make holes in the case to monitor the electrolyte level and its density. For many car owners, this is simply a matter of habit.

What happens if you pour boiled water

Some citizens confuse distilled water with boiled water. Let's find out further whether it is possible to add liquid from a kettle to jars of electrolyte. It is worth considering that boiled water differs in its characteristics from distilled water.

Some sources indicate that when boiling for more than 15 minutes in a kettle, all salts and minerals precipitate. This is not entirely true. Some of the dissolved substances actually accumulate at the bottom in the form of solid scale particles, but a significant percentage remains dissolved in the liquid.

The result of long-term heat treatment will be the following effect:

- the composition will be disinfected from bacteria and microorganisms that may initially be present in all aqueous solutions;

- when boiling, part of the water turns into steam, and minerals remain in the remaining volume of liquid, which ultimately increases their concentration;

- some of the salts will precipitate in the form of solid crystals;

- the result from pouring such a composition will be comparable to pouring from a tap.

How to identify a maintenance-free battery

Determining whether a battery is a maintenance-free product is quite simple. Upon visual inspection, this fact is indicated by the absence of plugs with a cross recess for a screwdriver. Some models may be serviceable, but the holes in such batteries are connected in the lid to remove gas for all cans at the same time.

Such a product can be easily identified by the hole located on the side, through which the internal space of the cans is connected to the atmosphere.

Attention! Sometimes battery manufacturers, like Beast, cover the plugs with a large sticker on the top cap, so tear off all the stickers before you start drilling holes.

If the battery is purchased remotely, and it is not possible to see its case in detail, then you should carefully read the information provided by the seller.

The product description does not always indicate the type of battery, but if it is reliably known that calcium technology was used in the manufacture of the battery, then all passenger batteries will necessarily have a maintenance-free case.

How to maintain and add water to a maintenance-free battery

Before you begin to independently change the design of the battery, you should evaluate all the pros and cons of performing such an operation. In many cases, the loss of the ability of a maintenance-free battery to produce a high discharge current is a sign of its imminent death. That is, the lack of water has already led to irreparable consequences. Even if we manage to bring him back to life, it is a fact that he will live a long time.

If the final decision is made to repair the battery, then you should take care of safety, because inside the battery case there are several liters of acid, which, if splashed, can cause serious damage to health. There are several ways to make a maintenance-free battery serviceable.

The most difficult option is to remove the top cover completely. This can be done using a hacksaw or a power tool, but such an operation will take too much time, and upon completion of the service it will be necessary to properly install this element back, which is an even bigger problem. Therefore, we do not recommend doing this.

You can only restore an acid-calcium battery; if you have an AGM, EFB or Gel battery, then nothing will work.

The easiest way to service this type of battery is to drill holes in the cover. A twelve-volt battery consists of 6 cans, so it is enough to make 1 hole in each compartment so that you can independently adjust the level and density of the electrolyte.

The plugs on the banks of a non-separable battery are made in the following sequence:

- Use a marker to mark the middle of each jar on the top lid. If the vertical walls are not visible on the body, then to perform this operation it is necessary to measure the width of the cover to the nearest millimeter. Then the resulting number must be divided by six. As a result of the calculations, the distance between the traffic jams will be obtained. The distance from the edge for the first plug can be obtained if the previously calculated result is divided by 2.

- To minimize contamination of the electrolyte with plastic shavings, it is recommended to drill the housing in 2 stages. First, you should make holes using a drill with a diameter of 3 mm at the points previously marked with a marker. After this, you should widen the holes with a tool whose cross-section is 12 mm.

- In order to tightly close such holes and thereby eliminate the possibility of acid splashing during use, you need to take 6 stoppers from medicinal alcohol extracts, for example, valerian, and install them in the holes made.

In this way, you can make a fairly high-quality conversion from one type of battery to another. Holes with a diameter of 12 mm allow, if necessary, to add distilled water or electrolyte if the problem of battery inoperability was a leak of an acid solution.

By the way! It is not necessary to drill large holes, just enough for the tip of the syringe to fit through. Then, using it, you can fill in the entire electrolyte in several stages. Then seal the holes with acid-resistant sealant.

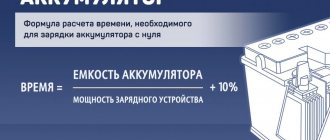

After replacing the electrolyte, how long should the battery be charged?

After the owner has independently replaced the electrolyte in the battery, it is necessary to keep the current source at rest for 4-6 hours. The liquid displaces air pockets and is evenly distributed in the space between the negative and positive plates. To speed up the procedure, periodic rocking of the battery case is allowed. Installing the product on the side walls or turning it over is strictly prohibited.

Then the battery must be charged by applying a current of no more than 0.1 A (using a charger with manual adjustment of parameters) for 15-20 hours. To restore functionality, it is necessary to carry out 2-3 cycles of charging and discharging (with measurements of the density of the working fluid). It is not recommended to bring the solution to the stage of intense gas evolution (seething), since water leaves the composition of the electrolytic liquid.

The final charging of the lead-acid battery is carried out with a current of 10% of the device’s capacity; the procedure stops after reaching a voltage of 14.5-14.7 V at the terminals. 2 hours after charging stops, a control measurement of voltage (12.6 V is considered normal) and density is taken.

If a gray deposit of lead sulfate is detected on the electrodes, then a reagent is introduced into the electrolyte, which decomposes the deposits in 36-48 hours. The substance does not impair the performance of the electrolyte.

During the process of capacity restoration, a change in the density of the electrolyte is observed. To reduce the parameter, pour distilled water.

If the volume of liquid rises above the permissible level, then the excess is pumped out with a rubber bulb.

Sulfuric acid electrolyte must not be poured onto the ground or into sewer pipes. The liquid is collected in a sealed container and handed over to an organization that disposes of toxic or aggressive substances.

Car batteries today come in two most common types: maintenance-free and serviced batteries. In the first case, only the ability to recharge the battery using a charger is implemented as standard.

The second type of battery allows you not only to charge the battery, but also to check the density of the electrolyte in the “banks” (sections) and analyze its condition. If necessary, the electrolyte level can also be increased or the fluid completely replaced.

Next, we will talk about why the electrolyte in the battery is needed, whether it is possible to add electrolyte to the battery and how to do it correctly. Frequent questions will also be discussed regarding which is better, distilled water or electrolyte in the battery, how the level is measured, how the electrolyte in the battery is completely replaced and the battery is subsequently charged.

Read in this article

What can happen when opening the case?

If you open the battery case, this will lead to the fact that the water from the electrolyte will constantly evaporate and the battery will need to be refilled as if it were being serviced. Disassembling the battery in any way will void the warranty . For modern products, the manufacturer's warranty can range from 12 to 36 months.

Important! If the battery is under warranty, then before opening it and repairing it yourself, take it to a service center, maybe they can help you there.

Disassembling a battery is not always possible without chips getting into its housing. In addition, during operation of a battery opened in this way, dust and dirt may get inside the cans. Foreign objects inside the case, to put it mildly, do not contribute to increasing the service life of the product.

Do you have any questions, haven’t been able to solve the problem, or have something to add to the article? Then write to us about it in the comments. This will help make the material more complete and useful!

Modern power supplies for cars require less and less human participation during operation. Maintenance-free batteries do not need to be topped up with water or electrolyte throughout their entire operating life. If the owner likes the battery, but the indicator indicates that the resource is exhausted, is it possible to restore the battery? How to open the battery and get the lead plates for fishing?

Is it possible to disassemble a maintenance-free battery?

The maintenance-free nature of the power supply is attractive for those who do not want to worry about the condition of the power source once again. At the same time, many are accustomed to monitoring all elements of the automotive system. It is traditionally believed that a closed battery cannot be opened. Indeed, there are no technical holes on the body of such batteries. However, if you want to make a car battery serviceable or remove lead from it, then you can disassemble a maintenance-free power supply. To do this, you will need some tools and knowledge of safety rules.

What types of lids are available?

The contents of any car battery are enclosed in a housing. Serviced batteries are distinguished by the ability to gain access to the banks and, if necessary, add electrolyte or distilled water. The maintenance-free closed-type battery is characterized by a smooth surface of the housing. To avoid any contamination, the upper part of the battery is retracted under the cover. It can be removable - with latches or monolithic - heat welded to the body. Most often, a closed type battery has a monocap.

How to make distilled water at home

Some car enthusiasts prefer not to buy distilled water, but to make it themselves. Usually these are people of the older generation, accustomed to times of scarcity and who do not want to change. But residents of remote villages where there are no shops have to adapt in a similar way.

Let us immediately note that it is impossible to obtain high-quality distilled water at home. To do this, you need a distiller, the cost of which is not comparable to the price of a bottle of water. As an alternative, you can use a moonshine still if you remove the coil from it. But the yield of distilled water with this method is insignificant - about a glass in 3-4 hours.

Distilled water has the formula H 2 O, that is, it does not contain foreign impurities. No matter how hard you try, it is almost impossible to get a similar result at home - a small part of the metal salts will remain in the water.

If you urgently need to top up the battery with water, put it in a plastic bottle and put it in the refrigerator for 2-3 hours. Then drain the unfrozen water into the sink, and melt the ice and use it to pour into jars. In this case, the damage to the battery will be minimal.

You can collect rainwater in a plastic container, then carefully filter it and use it for its intended purpose.

It is important that the water does not come into contact with metals. For example, the one that drips from tin roofs is not suitable for filling the battery.

What tools are needed for opening

To gain access to the filler holes, even if they are filled at the factory to the surface level of the case, you must remove the cover from the battery. How to open the battery cover? If it is on the grooves, then carefully unclip the fasteners and remove the element. You may need a flathead screwdriver.

A hot pressed part will not come off easily. During its dismantling, there is a high probability of the part breaking. Therefore, we do not recommend removing this type of element. However, if you wish, you can try to break the integrity of the part using an awl, screwdriver or drill. You will not remove the cover completely, but you will be able to make holes for further operations.

How to open a maintenance-free battery

There are not many ways to open a closed-type power source, and they depend on the intended purpose. If you need lead (for hunting or fishing), then you don’t have to worry about opening the battery and just break its case.

In order to extend the life of the battery, you need to make holes that will give access to the banks.

- Remove the stickers from the surface of the battery.

- Carefully inspect the body. Since the sealed lead-acid battery was filled at the factory, stamping of the plugs remained.

- Take an awl, screwdriver or drill and carefully make holes in place of the bays.

This simple procedure requires care, but allows you not to purchase a new power source, but to restore the functionality of the existing one.

How to turn a maintenance-free battery into a serviceable one

The time comes and the car owner is no longer satisfied with the characteristics of the battery. If you have a sealed battery, you shouldn’t throw it away and buy a new one. You can make it serviceable if you open the lid using the method we described above. This will allow you to carry out a number of procedures necessary to maintain the functionality of the power source.

The ability to check and change the electrolyte level is one of the signs of battery serviceability. Closed batteries are equipped with an indicator that allows you to see the electrolyte level. Some containers are made of translucent materials or have markings that help you keep track of the amount of solution in all jars. The electrolyte level can be checked using a special tube or syringe by inserting them into the holes made in the lid. The normal amount of solution corresponds to 10–12 millimeters of liquid above the plates.

Battery Maintenance

After a series of these manipulations, ensuring convenient maintenance, specialists carry out a complete diagnosis of the technical condition of the battery. Basically they consist of six points:

- Before deciding what to add to the battery: electrolyte or water, you must fully charge it with a special device.

- Next, measure the density in all jars using a hydrometer and record all the results in a notepad. When recording readings, it would be more convenient to put a number on each jar and indicate the value from the scale opposite it.

- If the density readings of a charged battery in some banks differ and are not within the recommended standard (1.25-1.29 g/cc), this means that the driver needs to make an adjustment. It is as follows: if the density reading is low, you need to calculate how much electrolyte to add to the battery and fill it, and if the density is high, add distilled water.

- The density of each can is at its limit, and for some reason the electrolyte level is falling lower and lower. The best solution for this problem is simply adding water.

- Sometimes it happens that the density in sections is lower than the nominal value (less than 1.21 g/cc). To find a solution, you need to take a small acid solution using a special enema and pour it into a measuring cup. Next, record the volume readings and pour the electrolyte into a glass mug. Using the technical table, pour the required amount of high-density sulfuric acid solution into a measuring glass and, using an enema, pour it into the jar from which the electrolyte was taken. In situations where there is a significant difference in the direction of decreasing density, it is best to add acid with a density of 1.40 g/cc. see. It is important to achieve the required level with distilled water.

- After the density has become the same in all banks, you need to connect the battery for a small recharge. This is done so that the recently poured solution is thoroughly mixed inside. After this, measure the density again, and if its level has changed, then repeat the operation.

Every car enthusiast needs to know that before switching to winter operation of the car, it is important to increase the density values in the battery, and lower it when switching to summer time.

And also every day before each departure you need to check not only the oil level in the engine, but also the cleanliness of the battery terminals and the reliability of the plugs on its body.

Safety precautions

- We strongly recommend using protective equipment when disassembling the power supply. It is strictly forbidden to turn over or shake the jars. This may cause a short circuit.

- If the battery cover is secured with fasteners, be careful not to break them. In the event of a breakdown, the part will have to be glued, and this does not guarantee safe operation of the power source.

- If you want to split the battery using a tool, choose special products that will help protect your eyes from splinters.

Can we safely say that a maintenance-free battery can be made into a serviceable one? Of course, a closed battery can be remade! If the purpose of opening the battery is to extract lead for fishing or hunting, then by observing a number of precautions, you can easily do it with just a hammer.

Buying a new one or repairing an old one is a dilemma for car owners whose battery has failed. For owners of modern maintenance-free batteries, it would seem that the choice is clear - buy. Ingenuity and knowledge of battery design will help extend the life of a “dead” energy source.

Winter is a real test for car enthusiasts. A working car may not start in the morning if the battery misfires. If you purchased a maintenance-free one and it let you down, don’t be upset, you can charge it, check it and continue using it.

Battery device

Lead-acid batteries are made of containers connected in series - cans. In jars, lead alloy plates are immersed in a sulfuric acid solution. Due to the reduction and oxidation of lead at the anode and cathode, a difference in electrical potential exists in the battery.

The main causes of battery failure:

- Electrolyte boiling away.

- Change in the chemical composition of the electrolyte.

- Dissolution of plates - sulfation.

- Short circuit in banks - the anode touches the cathode without a gap.

Types of batteries

Acid batteries can be serviced or maintenance-free. The serviceable one has special removable plugs that give access to the inside of the battery. You can check the density with a hydrometer and visually determine the level and color of the electrolyte. Maintenance-free batteries do not have this capability. Technologically, they are more advanced, since the evaporation of water from the electrolyte is minimized, and the sulfuric acid solution is designed for the entire service life of the device. Maintenance-free batteries are needed if they are installed inside a car.

When trying to make a serviceable battery out of a maintenance-free battery, you need to determine whether this is possible, more on that later.

Maintenance-free lead batteries are:

- With liquid electrolyte – WET

- With glass fiber core - AGM

- With gel electrolyte - GEL

fully serviced. Depending on the material of the plates, these batteries are:

- Antimonous: lead has excessive ductility; antimony is added to it for strength. Its disadvantage is that it is a catalyst for the electrolysis of water. the electrolyte level and density change. This type needs to be serviced more often. They are designated by the letters Sb.

- Calcium: the presence of calcium reduces the service life of the device - the plates quickly sulfate. There is practically no need to maintain such batteries, but the main thing is to prevent deep discharge. They are designated by the letters Ca.

- Hybrid: one part of the terminal is made of calcium, the second - antimony material. An excellent compromise - gas emissions are kept to a minimum. Designated Ca/Sb.

Only after first finding out whether your battery can be serviced should you proceed directly to work.

How to prepare battery electrolyte

To make an electrolyte of the required density with your own hands at home, you will need to prepare reagents and tools:

- sulfuric acid (to create a solution you will need up to 1 liter of liquid);

- distilled water (4-5 l, depending on the size of the battery case);

- hydrometer to determine the density of the solution;

- rubber gloves and acid-resistant protective apron;

- protective glasses;

- measuring containers;

- reagents for removing spilled acid or electrolyte (soda ash solution or ammonia);

- glass stable container for mixing components;

- glass rod for stirring reagents.

Before starting to prepare the solution, it is necessary to determine the volume of components required to obtain the liquid of the required concentration. For example, to form 1 liter of electrolyte with a density of 1.27 g/cm³, you will need 791 ml of water and 274 ml of sulfuric acid.

The required amount of distilled water is added to the glass container, the acid is poured in portions and stirred with a glass rod.

The resulting solution is kept at room temperature for 12 hours, then the electrolyte density is checked and adjusted.

Do I need to add water or electrolyte?

A new, maintenance-free battery that works properly in your vehicle does not need to be opened or serviced.

If it was subjected to a long recharge, turned over, or its performance dropped sharply - only then you need to think about either purchasing a new battery, or how to disassemble and restore the faulty battery.

When to service your battery:

- If it is visible to the light that there is less electrolyte in one jar.

- The voltage at the terminals is low and charging has no effect.

- capacity noticeably decreased.

- Electrolyte leaked due to damage to the housing.

- Carrying out restoration after battery sulfation.

How to change the electrolyte in a car battery and when it is needed

So, now let's look at a situation where a complete replacement of the electrolyte in the battery is required. Most often, a visual assessment and some other characteristic signs help to understand whether the electrolyte in the battery needs to be changed.

As a rule, the need for replacement is indicated by:

- cloudy electrolyte in the battery, color change;

- it is not possible to achieve the required density after charging the battery;

Experts also recommend completely changing the electrolyte in cases where a relatively new battery began to quickly discharge after being fully charged using a charger; during a check it was revealed that there was no electrolyte in the battery in one bank; the electrolyte had previously frozen, etc.

The next reason that the electrolyte is cloudy is damage and shedding of the plates. At the same time, one should not exclude the possibility of a short circuit in one section or in several at once. As a rule, the appearance of a cloudy gray precipitate indicates shedding of the plates; a black or dark color of the electrolyte is a sign of poor quality of the main components of the electrolyte (water and/or acid). A brown color indicates that the battery has a short circuit.

How to open the battery cover

Serviceable batteries have plugs for checking the cans. Getting to the contents of a maintenance-free battery is more difficult. There are no plugs, and the monolithic lid is a labyrinth for trapping and condensing vapors. Disruption of the labyrinth's passages will reduce the efficiency of the system. Therefore, before opening the battery cover, you need to weigh the pros and cons.

Attention! Before opening and checking the battery, it must be charged! The density of the electrolyte on a discharged battery is significantly lower!

Here are some options for how to get to the electrolyte:

Let's sum it up

Now you know how to add distilled water without damaging the battery. We recommend purchasing a hydrometer to monitor the density of the electrolyte in the jars. Without this device, it is impossible to achieve the required density, and changing it can damage your battery. Watch the video on the topic to get a better idea of the process.

The average battery life is 3 years. After this, the electrolytic liquid loses its properties and stops working normally.

For maintenance-free batteries, everything is simpler. They serve for more than 6 years without problems, since the liquid level there is regulated independently. Maintenance requires constant monitoring and timely filling. To the question: “What can you put in a battery?” — we answer in detail in this article.

The easiest way is to add distilled water to the battery, since this is what evaporates. Violation of the water-acid balance leads to a gradual loss of charge.

Do-it-yourself repair - how to restore the battery correctly

Having reached the electrolyte, you need to check three parameters:

- Color. The electrolyte should be transparent, without foreign inclusions. The collapsing lead plates give the liquid a dark color.

- Level. As water evaporates, the electrolyte level drops, which reduces power. Each battery has its own liquid level parameters, but all batteries must have plates immersed in electrolyte.

- Density. It is checked with a special device - a hydrometer. The density of the electrolyte in a charged battery is 1.27.

Important! When working with electrolyte, use personal protective equipment! Wear goggles, protective gloves and a respirator. Electrolyte splashes in the eyes or on the skin will cause a chemical burn.

The procedure for diagnosing a maintenance-free battery is as follows:

- We check the voltage of the battery and the vehicle's on-board network. This is necessary to prevent chronic undercharging of the battery. During short, frequent trips, the battery does not have time to charge; as the temperature drops, the capacity drops by 20 - 40%. Many owners blame working equipment, although it needs to be operated correctly.

- We charge the battery. For charging, it is advisable to use a factory-made charger, preferably with a controller. The use of electronics will increase the accuracy of the charge. If the charger is idle, set the current to approximately 0.1 of the capacity. A 60 A/h battery needs to be charged with a current of 5 - 6 Amps. Charging continues. until the ammeter readings drop to 2-3 amperes. A severely discharged battery needs to be charged with a current of 1-2 amperes (about 1/20 capacity) for several days. The voltage should not exceed 15 volts, otherwise the jars will “boil” and may swell.

- Drill holes in the battery cover. We check the electrolyte level using an improvised dipstick. If the battery case is made of light plastic, then the level can be checked by shining a flashlight through the battery.

- We check the density with a hydrometer.

- After checking and topping up, the battery must be tightly closed.

How to correct electrolyte status

There are three options for correcting electrolyte density:

- At a normal level, low density. We use a hydrometer to take out the entire contents of the jar and pour it into a glass container. Add concentrated acid and bring the density to the recommended level. Fill the electrolyte into the jar to the level.

- When the electrolyte level is low, the density is high. You need to add distilled water, stirring the electrolyte with a glass rod. After work we measure the density.

- At normal levels, high density. Drain the electrolyte, add distilled water, fill to the level.

Important! The density of the electrolyte is its main characteristic. The entire operation of the battery depends on maintaining this parameter normally.

When performing battery maintenance, you can drain all the electrolyte into a glass or enamel container, stir and check the density. Pour the normal electrolyte back into the jars, and if there is a shortage, add fresh electrolyte with the appropriate density. Topping up should be done evenly into all jars so that the amount of fresh sulfuric acid is the same in all jars.

Operation after maintenance

Once opened, a maintenance-free battery loses its sealed properties. It is better not to use this type if the structure is turned over or is standing in the car.

Any interference with the labyrinth lid will lead to loss of the properties of capturing and condensing distilled water vapor. The repair turns a maintenance-free battery into a serviceable one. You will have to look into the battery more often.

Complete battery maintenance by charging. It is discharged by connecting several energy consumers, and then charged. small currents. After two or three charging cycles, it is advisable to check the battery with a load plug. If the battery capacity has dropped sharply, you should decide to replace it.

How do the properties of the electrolyte in a vehicle battery change?

To fill the battery, a mixture of distilled water and sulfuric acid is used. During the course of electrochemical reactions, water decomposes and evaporates, vapors condense on the inner walls of the case or escape into the atmosphere through ventilation holes. The volume fraction of acid in the solution increases, which, together with the low level of liquid in the jars, negatively affects the capacity and service life of the battery.

At the final stage of battery charging, oxygen is released at the positive electrodes, which can be restored at the negative element. But due to the presence of liquid, the process slows down, which leads to the release of gas from the battery and a drop in the electrolyte level. The use of sealed cases has reduced the evaporation rate, but during discharge, lead sulfate is formed on the surface of the plates, which does not decompose during the charging of the power source. Because of this, there is a drop in the density of the electrolyte, which negatively affects the battery capacity.

The lead used to make electrodes reacts with water molecules. As a result, the density of the electrolyte changes, and foreign impurities appear in the solution, worsening the performance characteristics of the direct current source.

To eliminate the negative effect, alloying additives are introduced into the alloy composition to reduce the corrosion rate.