The clutch is a component due to which many people respect a manual transmission: it makes it possible to fully control the car without depending on electronics. And it can also cause a forced stop far from home.

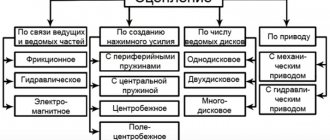

Purpose and design

The clutch serves to briefly disconnect the engine from other transmission units and then smoothly connect them. When the clutch is engaged (pedal released), torque from the engine to the gearbox is transmitted through the driven disk, which is pressed tightly to the flywheel by the pressure disk. In modern passenger car clutches, the pressing force is provided by a diaphragm spring. The latter is connected to the basket (mechanism casing) and the pressure plate.

The clutch rarely breaks suddenly - the malfunction develops as it wears, gradually changing the way the transmission operates.

To disengage the clutch, the design includes a release bearing that presses on the spring diaphragm. The force on the bearing is transmitted from the clutch drive (mechanical or hydraulic) using a pressure fork. By bending, the spring moves its peripheral part away from the pressure plate and relieves the pressure on it. Once freed, the driven disk stops transmitting torque to the gearbox input shaft. When the clutch pedal is released, the transmission of torque to the transmission is smoothly restored.

The most modern transmissions have two clutches in one basket.

Types of breakdowns

The most common clutch malfunction is wear of the friction linings. Their service life depends on driving style and quality and ranges from 100-250 thousand km. If the disc is not replaced in time due to the destruction of the friction linings, it can lead to wear of the flywheel and pressure plate, as well as jamming of the entire mechanism. The splined connection of the gearbox shaft and the driven disk, the release bearing, and the central part of the diaphragm spring at the point of contact with the bearing are also subject to wear. On older cars, the riveted joints of the pressure plate and basket “suspension”, parts of the driven disk, and the fork support may be destroyed. A break in one of the spring plates on which the pressure disk is suspended leads to its distortion and slipping of the disks. It happens that an overheated slave also warps. Due to severe overheating or “fatigue,” the diaphragm spring weakens.

Through a damaged crankshaft or gearbox shaft oil seal, oil can enter the basket, which will prevent normal communication between the discs. On a car that has been left idle for a long time, the discs may become stuck. Failure to adjust the clutch drive leads to limited travel of the fork and discs.

Repair

When the clutch wears out naturally, the entire basket assembly is usually replaced - the drive and driven discs, the pressure spring with housing, and the release bearing. If a relatively new clutch is “burnt” due to careless driving, it is often enough to replace only the driven disc. In principle, only worn friction linings can be replaced. Installing a new release bearing is sometimes only possible together with the hydraulic drive working cylinder.

Signs of damage

Most often, drivers complain that the clutch “leads” or “slips.” That is, it doesn’t turn on completely (less often it doesn’t turn off). The first problem manifests itself in difficult gear shifting, driving with the clutch depressed and the gear engaged. The reason is a warped driven disk, misaligned drive. Another “culprit” is a worn-out release bearing, which, in addition, makes noise when the pedal is pressed. The clutch does not disengage at all if the drive fails, the release bearing is destroyed, or the linings, springs, or rivets that have separated from the discs become jammed. With a “slipping” clutch, the acceleration of the car “lags behind” the increase in engine speed, and on a steep climb the car can stop while the gear is engaged. This malfunction is often accompanied by a specific burning smell. In addition to critical wear of the disk, the cause of slippage is oil that has leaked onto the disks through the seals, or a broken petal of the pressure disk suspension. In the baskets of older model machines, disc slipping may be caused by a weakening pressure spring(s).

If the car jerks even when the pedal is slowly released, and no defects are found in the clutch drive, there is a high probability that the driven disk is stuck on the worn splines of the gearbox shaft. The same effect is caused by cracks and scuffs on the disks, as well as warping of the pressure, driven disks and flywheel. Driving of any intensity should occur without jerking in the transmission.

Main symptoms of a malfunction

1. Jerking when starting 2. Difficulty shifting gears 3. Noise when the pedal is pressed 4. Burnt smell 5. Inconsistency between acceleration and speed

Clutch malfunction problems

may be different even for cars of the same model and year of manufacture. There are two main reasons here: the operating conditions of the car and the driving style of the owner.

So, if the car is constantly driven in the urban cycle, then the driver has to use the clutch pedal more often than when driving on the highway. Accordingly, it wears out faster.

Driving style also affects the life of the clutch. For example, active driving shortens the life of the unit, as well as the habit of many drivers to keep their foot on the clutch pedal.

In addition, the service life of the unit undergoing repair is affected by the quality of the spare parts used for replacement.

The working clutch should disengage completely when you press the pedal, and not slip when you release the pedal, and the on/off operation itself should be silent.

When the listed conditions are not met during operation of the unit, then it’s time to start checking the clutch.

Signs of a bad clutch

:

· Noise during operation of the unit;

In cases where noise appears when you press the pedal, or, on the contrary, disappears, then there are signs of a breakdown of the release bearing. The clutch release bearing is to blame. Before replacing the bearing, you need to check the adjustment of the release fork, as the new bearing can quickly fail.

Quite often, noise when switching off is caused by wear of the splines of the driven disk, this is especially observed in disks where the ferredo linings have been repeatedly replaced. The noise can also come from a worn gearbox input shaft bearing. The source of noise can also be the return spring of the clutch fork, which has lost its elasticity (or is lost or has jumped out of place), as well as worn or broken springs, or other elements of the torsional vibration damper of the driven disk.

“Drives” the clutch

When the clutch is not fully disengaged, gear shifting occurs with difficulty and is accompanied by a grinding noise; sometimes it is simply impossible to engage a gear.

With such signs of a broken clutch, there may be several reasons, such as:

·Installing a new clutch disc of increased thickness when there is not enough travel of the basket pressure plate;

· Loosening of rivets or breakage of linings as a result of handicraft repair of the driven disk;

·Deformation due to overheating when the pressure or driven disks slip;

· Faulty petals of the basket diaphragm spring or breakage of the drive disk;

· Sticking of the driven disk to the flywheel, usually after the car has been parked for a long time;

· Malfunctions in the clutch drive. In a mechanical drive, the condition of the cable and its adjustment, in a hydraulic drive, the presence of air in the system.

Clutch “slips”

A clutch malfunction in such cases manifests itself in sluggish acceleration, and when climbing, it feels like the engine has lost some of its power. Plus, a specific burning smell appears from burning linings.

All these signs clearly indicate that the clutch disc is worn to the limit and requires replacement.

Clutch slipping can also be caused by oiling of the flywheel, driven and pressure disks, as well as warping of the driven disk when it is pressed against the flywheel surface only by the edges, and not by the entire plane. This, by the way, can also cause jerking when starting off, even when the pedal is released smoothly.

Replacing a clutch is quite a labor-intensive operation and expensive, so it is recommended to replace the entire clutch kit at once.

These are the basket, clutch disc and release bearing.

Replacing the kit will firstly increase the resource of the unit as a whole and guarantee long-term operation. If you replace only the driven disk, then there is no guarantee that the basket or release bearing will not fly off soon.

You should not delay repairing the clutch, since a disk worn to the point of rivets will easily render both the flywheel and the basket unusable. A faulty release valve can “destroy” its own guide and diaphragm spring of the driven disk. Play in the hub of the driven disk provokes damage to the input shaft of the gearbox, etc.

Don’t wait until the car can simply stop on the road, when you can move on only with a tow truck or a tow truck.

I welcome you, friends, to the website for DIY VAZ car repairs. One of the main components in a manual car is the clutch. Its task is to separate the motor from the transmission at the driver’s command and make it possible to smoothly change gears.

In addition, the clutch dampens unnecessary vibrations and protects the transmission from overloads. Unfortunately, operating errors, aggressive driving style and untimely maintenance can lead to unit failure.

At the same time, you, as a good driver, should clearly know the symptoms of a clutch malfunction and how to eliminate them.

Major clutch failures

It is no secret that the clutch is a complex mechanism consisting of many elements and parts.

Consequently, there are dozens of possible breakdowns. For ease of identification, experts distinguish two types of malfunction:

1. Failure of the clutch itself:

- Damper springs are worn out or deteriorated;

- driven disk;

- release bearing;

- pressure plate or flywheel surfaces;

- splined part of the driven disk;

- bending or oiling of the driven disk;

- biting the clutch fork.

2. Clutch drive failure.

There are problems here:

For a mechanical drive - a violation of the integrity of the lever system, as well as failure of the cable (its elongation, damage or jamming);

For a hydraulic drive - the appearance of a leak or airiness in the system, dirt in the hydraulic drive, failure of the working cylinder (for example, the integrity of the cuff may be compromised).

Causes and malfunctions of the clutch

The clutch is a very sensitive unit, the breakdown of which can be caused by many reasons:

Errors in operating a vehicle (a common problem for beginners) - keeping your foot on the clutch pedal, starting to move at high speeds, driving with the pedal depressed, and so on. When driving like this, the clutch does not hold up for long and quickly fails.

Natural aging (wear and tear) of one or another element. For this reason, the driven disk most often breaks down, the service life of which is about 100 thousand kilometers. Fans of fast driving wear out the driven disk two or even three times faster.

Low quality parts. Against the backdrop of an increasing volume of counterfeits on the shelves of markets and shops, this problem is more relevant than ever. To avoid it, buy only original spare parts.

Oil getting on the friction linings. This problem occurs when the seals fail or due to wear.

External signs of clutch failure

As a rule, most clutch failures can be diagnosed by a number of external signs - sounds, vibrations, and so on.

Let's look at the most popular of them:

The clutch does not engage (or engages, but not completely). This problem can be easily identified by the problem with turning on the speed when the car is running.

Extra noise often appears in the gearbox - crackling, noise. In addition, the problem may manifest itself as an increase in free play.

Drives the clutch (does not disengage). It's easy to check the fault. Engage first gear and start driving. Now squeeze the clutch and the car will continue to drive as if nothing had happened.

There may be several reasons - the splines or linings of the driven disk are worn out, the disk itself is damaged, the diaphragm spring is weakened (failure), the hydraulic drive is clogged, the lever system is broken, the cable is stuck (damaged), damage appears in the drive system, and so on.

How to fix? Depending on the problem, adjust the cable, replace the disc, fork or flywheel, clean the splines from dirt, change the casing (it is advisable to do this immediately with the pressure plate).

When the clutch slips, you can smell a strong burning smell in the cabin. As a rule, the friction linings of the disc “suffer” from this.

In addition, clutch slipping can manifest itself as increased gas consumption, deterioration in dynamics, and overheating of the power unit.

The main reasons for “slippage” include oil getting on the driven disk, jamming of the fork on the unit switch, biting of the cable, failure of the working cylinder, contamination of the hydraulic drive, contamination of the hydraulic drive system, problems with the diaphragm spring, and so on.

These problems can be corrected in the following way: clean the surfaces from oil, change the driven disk, install a new clutch, replace the drive.

Jerking when the clutch operates. You try to start moving smoothly, but nothing works - the car starts jerkily. There are several reasons for this - failure of the damper springs, loosening of the mounting supports on the engine, a defect on the pressure plate, bending of the diaphragm spring, “sticking” of the driven disk hub, and so on.

In this case, you need to change the driven disk, lubricate the cable (change it), clean the splines from dirt, change the gearbox disk or input shaft;

Strong vibrations when pressing the pedal. Such a malfunction is felt immediately, because vibration is transmitted to the whole body.

There are several reasons - curvature of the driven disk or diaphragm spring, natural wear of the splines, oil getting on the disk, etc. Here it is only possible to replace the driven disk.

Noise appears when the pedal is released. Everything is simple here - you disengage the clutch, and at the same time very loud sounds appear. There is only one reason - failure of the release bearing. The bearing must be replaced.

At the first sign of clutch failure, repair the problem. Otherwise, a breakdown can take you by surprise on the road and cause a lot of problems. Good luck on the roads.

One of the most important components in a car is the clutch. It can be of different types, but it performs a single function - transmitting torque. The latter comes from the flywheel to the gearbox input shaft. The transmission and engine are not permanently connected. To enable the required speed, these units must be disconnected. The clutch mechanism handles this function. The unit is very reliable, but over the years it causes some problems. Therefore, in today’s article we will look at possible clutch malfunctions and how to eliminate them.

How does the clutch work and why does it burn?

A clutch is a device that is designed to break the torque between a car’s transmission and its engine. The clutch allows us to change gears and ensure that the car starts moving smoothly without jerking.

As the crankshaft rotates, the engine flywheel rotates along with it at the rear of the crankshaft at the same frequency. The flywheel's job is to transmit torque to the input shaft of the gearbox and then convert it. In order to ensure smooth gear shifting and a smooth start to movement, it is necessary to create a break in the mechanical connection between the engine flywheel and the gearbox input shaft.

To ensure this gap, a special device called a clutch was developed. The clutch consists of a clutch disc, pressure plate and drive mechanisms. The disk is pressed against the flywheel by the force of the spring and bearing; the other side of the disk is rigidly engaged with the transmission input shaft.

When you press the clutch pedal, the drive mechanism moves the clutch disc away from the flywheel, overcoming the force of the return springs. The driver engages the gear and smoothly releases the pedal. The disc begins to press against the crankshaft, is set into rotation and spins the transmission. Then the wheels are put into action and, as the car accelerates, the rotational speed of the disk, after a little friction, is combined with the rotational speed of the crankshaft.

How does it work?

Let's look at the operating principle using the example of a classic single-plate dry clutch. So, to turn it on, the driver presses the appropriate pedal. The pressing forces are transferred to the working cylinder. Next, the rod pushes the fork. The latter affects the clutch mechanism itself. The bearing begins to press on the pressure plate petals, and they bend towards the flywheel. So the box begins to work independently of the engine.

The engine is idling. At this point, you can engage the appropriate gear. In order for the engine to retransmit power to the gearbox and the car to continue moving, the pedal is released. Under the action of the drive elements, the disk again comes into contact with the flywheel. The smoother the driver releases the pedal, the softer the torque is transmitted. And if this rule can be neglected at speed, then when starting off you need to try to release the pedal as smoothly as possible. Below we will look at the main clutch malfunctions and methods for eliminating them.

Correct use of the clutch pedal

The clutch should be depressed without delay and all the way. When releasing it, the leg should move smoothly, without “throwing”; it is possible to stop when reaching the grasping point.

You should not hold the clutch in the pressed position for a long time.

The movement always starts from first gear. Experienced drivers sometimes start from the second on slippery winter roads.

The clutch is the main structural element in the transmission of any car. This mechanism serves to briefly disconnect the engine from and also to smoothly transfer torque from the engine flywheel to the gearbox. Thus, the clutch is designed to protect transmission components from various overloads. This mechanism is located between the internal combustion engine and the gearbox. In today's article we will look at the signs of a burnt clutch in a car, as well as ways to solve this problem.

Incomplete shutdown

This problem is popularly called “drive clutch”. The cause of the malfunction may be incorrectly set clearances of the clutch release drive. In this case, it must be adjusted in accordance with the factory parameters. Domestic cars often have problems with the clutch pedal. You should set it to free play and the problem will be solved.

Other clutch malfunctions also occur. So, if it is not turned off completely, the driven disk warps. The manufacturer allows an end runout of no more than half a millimeter. Otherwise, it should be replaced with a new one. When disassembling the basket, carefully inspect the condition of the disk. The latter should not have unevenness on the friction linings and traces of burning.

In rare cases, clutch malfunctions occur due to the wedge of the driven disc hub on the spline of the gearbox input shaft. How to solve this problem? It is necessary to clean the splines and coat them with a specialized lubricant (for example, LSC-15). If the drive clutch problem persists, replace the drive plate or input shaft assembly with a new one.

Air in the system

Most modern cars use a hydraulic clutch drive. Brake "Dot" of the third or fourth class is used as a working fluid. What are the signs of a bad clutch? If the pedal is soft and the fluid level is at a minimum, you should bleed the system of air and restore the level. How to bleed the clutch? Locate the hex valve on the slave cylinder. Usually it is unscrewed with a “10” key. Pre-pressurize the system by pressing the pedal 5-7 times. Next, unscrew the valve - you will see how the airy liquid comes out. Repeat the procedure until the air is completely gone from the system.

Do not forget to maintain the fluid level in the tank - if it leaves, air will automatically be “sucked” into the system and all work will have to be repeated again. What should I do if after bleeding the pedal becomes soft again? In this case, it can be stated that the working cylinder rod seal is faulty. Liquid may ooze from under it; air leaks from the outside are also possible. You need to look for the place of depressurization and localize it. These could be boots, hoses, or sealing parts in the clutch master cylinder.

Slipping clutch

Another common problem that motorists face. The reason may be that oil has penetrated the friction lining of the disc. Because of this, there will be insufficient engagement with the flywheel and a constant burning smell. These are the main signs of a faulty clutch that is slipping. The car is unable to start normally and continue moving; jerking during acceleration is often possible.

All this indicates incomplete engagement of the clutch. Among other reasons for this malfunction, it is worth highlighting:

- Increased wear of the friction linings of the disc (we will talk about its service life a little later). Solved by complete replacement of the element. If oil gets on its surface (this will be visible by characteristic stains), you should clean the element with white spirit or another degreaser. But this is only possible if the damper springs are intact and there is little wear on the linings themselves.

- Clogged compensation hole on the clutch master cylinder. Eliminated by cleaning (rinsing) the holes.

- Drive damage. This could be a deformed fork or a faulty slave cylinder.

What does the smell of a burnt clutch mean?

As you already understand, the clutch is a part that operates under constant load, in conditions of increased friction. It bears the entire load when starting the car and running the engine at high speeds.

https://www.youtube.com/watch?v=ytcopyright

Improper use of the clutch will inevitably lead to premature wear. Illiterate use consists of prolonged operation of the engine at high speeds. An example of such work can be considered prolonged acceleration of the engine in a low gear or slipping. In addition, prolonged use of the clutch has a detrimental effect on the clutch, when the driver starts to move away, adding gas, but releasing the clutch too slowly.

- Firstly, do not panic, even if the burning smell is too strong. Burning does not always appear when the disk is completely burned. It only means that the friction linings simply heated up during friction and slightly oxidized. During operation, they will be restored, and the clutch can be used for quite a long period.

- Secondly, complete wear of the clutch manifests itself without a characteristic odor. The car will lose its dynamics, and may not be able to climb at all.

Noise when disengaging the clutch

This problem is easy to recognize. But often it is not given due attention. So, when you press the pedal, the car stops making a characteristic rustling sound. But as soon as you let go of it slightly, the sound resumes again. This indicates that the clutch release bearing has failed. Its malfunctions may be due to lack of lubrication, play in the holder or natural wear. The element is non-separable and cannot be repaired. The release bearing is replaced entirely with a new one.

When purchasing, you should make sure that there is lubricant. Or rather, in sufficient quantities, since unscrupulous manufacturers simply do not report it inside. This is the main reason for premature bearing failure. But moisture also contributes to this. When crossing fords (if you have an SUV), you need to be careful. Otherwise, water will get into all clutch assemblies, which will significantly reduce their service life.

If noise occurs when the clutch is engaged, it means that the damper springs have failed or the fork has come off. In rare cases, this is a breakdown of the plates that connect the pressure plate to the housing.

Master disk resource

How long does this element last? Manufacturers do not provide exact data.

But as practice shows, the average life of the drive disk is from 100 to 150 thousand kilometers. Below we note several factors that significantly reduce its resource:

- Aggressive driving style

. Constant movements at high speeds with a sharp release of the pedal have an adverse effect on the condition of the friction linings. - Driving with a load

. This is especially true for commercial vehicles. For example, let’s take the GAZelle, whose gearbox is no different from the Volgov’s. This kind of drive is simply not designed for high loads. Even when the pedal is released smoothly, the friction material will slip through the flywheel and simply burn due to friction. The resource of such a disk is not even 15 thousand kilometers. The same goes for the trailer. Do not overload the mechanisms - the clutch, master cylinder and much more will suffer. - Incorrect towing

. You should not pull a car that weighs one and a half or more times the weight of your car. This will quickly burn out the drive disk.

So, we have found out the main clutch malfunctions and methods for eliminating them.

Clutch malfunctions are perhaps the most unexpected and unpleasant, because in most cases the car is completely immobilized. Read about what types of clutch malfunctions there are, as well as how to repair the clutch.

The most common clutch failures are:

- incomplete shutdown (in this case, gears are difficult to shift or do not shift at all);

- the clutch slips when the pedal is released (a burning smell is felt, the car does not develop speed, and has difficulty climbing hills);

- not smooth engagement of the clutch with jerking and vibration;

- noise in the clutch mechanism when pressing the clutch pedal;

- noise in the clutch mechanism when the pedal is released.

Why is the clutch burning?

The first and most common reason why the clutch burns is increased load on the car. What is meant by this concept? First of all, this is an aggressive driving style. Due to frequent and sudden starts from a standstill, the clutch disc spins and burns out. When driving in higher gears, the torque is not as significant, and therefore the risk of disc burning is minimized. As statistics show, it is during sharp starts from first gear that the clutch burns.

But it is not only an aggressive manner that can lead to such problems. For example, let's take the GAZelle car. It would seem that this truck is unlikely to be used for aggressive driving. But there is another problem: overload. It is because of overload that the load on the clutch and other components increases. The driver, in an attempt to move off, applies gas, or increases engine speed. Accordingly, the torque also increases. This moment is too large, and therefore the disk begins to partially scroll when it comes into contact with the flywheel.

The situation is similar with cars that tow a trailer. If the latter is significantly loaded, there is a high risk of burning the clutch. Of course, during rare trips it is impossible to completely wear out the disk, but its service life will definitely decrease.

Another situation that can lead to slipping (and, accordingly, burning) of the disk is towing another car. According to traffic regulations, the weight of the first vehicle must be higher or at least not less than the one being towed. Otherwise, the clutch suffers increased wear and sometimes burns badly. Similar cases occur during winter operation. A striking example is when a car got stuck in the snow. While trying to get going, the driver burns the clutch, unaware of the consequences.

Clutch faults

So, now let’s look at them in more detail and determine how to eliminate them.

The clutch can be mechanically or hydraulically driven. Incomplete disengagement of the clutch can occur due to a low level of brake fluid in the fluid reservoir, as well as incorrect adjustment. The fluid level must be periodically monitored, and if it is not within the normal range, brake fluid must be added. If the fluid level in the nutrient tank constantly decreases, this indicates a violation of the clutch hydraulic drive tightness (fluid is leaking), as well as possible wear of the clutch working cylinder. This problem can also occur due to air in the hydraulic drive system. To remove air, it is necessary to bleed the system.

Ideally, you need to drive onto a lift or overpass and carefully inspect the clutch slave cylinder for leaks. This is especially true in winter if the fluid has not been changed for a long time. In general, the “brake fluid” is very hygroscopic, which means it attracts moisture well. Therefore, it must be changed approximately every three years.

It happens that after the car has been parked for a long time, the speeds refuse to turn on at all. This is due to the fact that the driven disk has become soured to the flywheel and pressure plate. In this case, you need to press the clutch pedal several times, and then try to turn on the speed again; if this does not help, you can turn off the engine, turn on the speed, press the clutch pedal, tighten the handbrake and carefully try to start the engine. If these procedures do not help, then you need to contact a service center to repair the clutch. If the car does not pick up speed and has difficulty climbing hills, this indicates that the clutch is not completely disengaged. This happens due to wear on the linings on the clutch driven disc, wear on the drive disc, or improper adjustment of the clutch drive. When operating a car under normal conditions, replacing the clutch is required after 100 thousand kilometers.

Another clutch malfunction can be expressed in vibration and jerking when starting to move. The reason for this may be deformation of the driven disk, as well as oiling of its friction linings. The latter may occur due to wear of the crankshaft oil seal or the input shaft of the variable transmission. In order to check this, you need to leave the car on a flat, clean place overnight, and in the morning look under it from the front. Detection of drops or puddles of oil may indicate the presence of this malfunction.

Another malfunction of the clutch mechanism can be determined by opening the window and pressing the clutch pedal. If you hear extraneous noise and a grinding noise from under the car, which disappears when you release the clutch pedal, this indicates a faulty release bearing. There is no point in delaying its replacement, because... in the event of a complete breakdown (if it jams), the clutch pressure plate will be destroyed, including other clutch parts, and the clutch casing and variable gearbox housing may also be damaged, which will entail large financial costs. Therefore, when replacing clutch parts, the release bearing must also be replaced.

It may work properly, but after several years of operation, the lubricant in it dries out and is expelled. Naturally, a dry bearing cannot work for a long time.

But if the clutch pedal is released and the noise does not stop, then most likely this indicates destruction of the driven or pressure plate, which in turn will require replacement of these parts. It is also, of course, rare, but it happens that one of the gearbox input shaft bearings is humming.

What to replace?

Many motorists are wondering what to change. A burnt clutch cannot be restored or repaired. Therefore, a completely new driven disk is installed on the car. In addition, experts recommend inspecting the condition of the pressure plate. If the petals are bent, this element must also be replaced. In addition, the release bearing needs to be replaced. Its resource is slightly higher than that of the disk. But if you take the box apart, then install a new bearing. Otherwise, you will have to disassemble the transmission again, after 10-20 thousand kilometers. And this procedure is quite labor-intensive and painstaking.

So, we have found out the signs of a burnt clutch and the causes of this phenomenon.

If the engine roars loudly, the car accelerates slowly, and there is a distinct burnt smell in the cabin, then this clearly indicates that the clutch disc has burned out.

So, let's look at the reasons why clutch discs may burn.

Bravado and idiocy are different concepts, but, unfortunately, they often go hand in hand. For example, in winter a motorist “sat” in a snowdrift. His actions? Well, that's right: gas to the floor (so that you can reach the ground)! But it is in this way that he himself burns the clutch discs. But going out and putting branches under the wheels or the same “shoe” or jack is weak?!

In the summer?! Well, where did this habit of accelerating while slipping come from: so that the tires squeal and smoke pours out from under them? Result: clutch discs burn. How they burn: they turn blue. And the blue color is an indicator that the metal is overheated and has become very fragile and thin. What kind of normal clutch can we talk about?

Diagnosis of clutch problems

You got into the car and pressed the clutch pedal. Do you hear creaking and squealing noises? Then you have problems with the release bearing: it is worn out and jammed. And this is very bad, since it is this part that allows you to connect the gearbox to the engine and change gears without jerking. The solution is to immediately replace the part!

When you get to the service center, you should not blindly trust the specialists with your car. You must understand that the best rule in this case is “trust but verify.” Stay nearby and follow the car diagnostic process. For example, if your release bearing is broken, then it is not at all necessary to change the clutch disc and basket, but the master can offer you this, because this is his income.

If the clutch is hydraulic, then the clutch pedal may simply fall through and not return to its original position. This indicates that one of the cylinders has broken: the worker or the main one.

If air gets into the hydraulic system of the clutch control mechanism, it is necessary to carry out.

If the clutch drive is mechanical, then thin steel cables are involved in the process. They can tear, stretch or come off. Naturally, the car won’t move: the pedal doesn’t work.

Getting to the clutch on a car with rear-wheel drive is very simple: in this case the box cannot be removed, you just need to carefully push it aside. If it is front-wheel drive, the box will have to be removed.

We remove the clutch disc and look at its condition. As a rule, a burnt disc becomes thin and blue: the consequences of overheating. Such a disk should be replaced along with the basket, which burns at the point of contact with the disk.

If everything is in order with the disk, then we look at the bearing. Rock it by hand: if it dangles (there is play), then the bearing should be replaced.

And one last thing. When the service technician installs the clutch in place, we strongly recommend that you ensure that he centers the disc! This process is carried out using a special mandrel. If this is not done, then when assembling the box the input shaft will not fall into place. We do not recommend inserting the shaft with force: it may break, and this already threatens to repair the gearbox.

Sometimes, although rarely, this happens: you press the gas, “the engine roars,” as the famous song says, but the car doesn’t move. Or it goes, but slowly. The specialist will immediately say: “The clutch is dead,” and he will be right, but being right does not make it any easier, but even harder - after all, there will be expenses to replace it (the clutch).

When the clutch, or more precisely, the driven clutch disc, dies a natural death, when it has lived its allotted life, then this is normal. You can consider the clutch a consumable item. But sometimes it also happens that the owner of the car, through his actions, shortens the already not very long life of the driven disk, or even simply “kills” it.

First, let's talk about what this clutch is: it is a sandwich, where a driven disk made of a special material with a high coefficient of friction is clamped with terrible force between two metal drive disks. While this most terrible force of the clamping springs compresses the disks, then, provided that the driven disk is not worn out and has sufficient thickness, they can be considered a single whole. But as soon as you press the pedal, that is, “squeeze the clutch,” this whole sandwich ceases to be a single whole. The engine is spinning, the car is standing still - the driven disk is in place, and the two metal disks surrounding it are rotating along with the crankshaft, and you calmly engage first gear. You can’t drop the clutch - any motorist knows this from the time he studied at a driving school. You need to move off smoothly, and this smoothness is achieved by the fact that the middle driven disk slips for some time when the clutch is engaged, which leads to intense heating of the clutch and wear of the disks.

If the car is overloaded, then the process of moving away takes much longer than usual. At the same time, to prevent the engine from stalling, you have to slip the clutch for a long time, which leads to its accelerated wear and premature death. Some of my friends, having loaded almost a ton onto a passenger car, which, even though the car was a station wagon, was clearly too much, burned out the clutch on one trip to Kamensk. The same thing happens when the handbrake is pulled up.

A worn clutch fails very quickly - it slips a little, but this “slight” is enough for the entire assembly to heat up, then begin to burn, this causes the clutch to slip even more, the temperature rises - a vicious circle, but it turns out. The result is smoke, the smell of a burnt Ferodo, the engine is running, but the car is not moving.

Another option to easily burn out the clutch is to drive an ordinary modern high-speed passenger car into impassable mud. You will have to keep the speed high so that the engine pulls out, and at these high speeds you will have to actively slip the clutch so that the engine pulls out again. It’s the Niva that has a low gear in the transfer case, which you can use not only to drive out from anywhere, but also to plow your garden, but you still shouldn’t get into the mud with a regular car.

And one more thing: you shouldn’t stand at traffic lights waiting for the green light with first gear engaged and the clutch depressed. Of course, now that release bearings are widespread to replace outdated graphite thrust bearings, this is not so relevant, but a bearing under such a heavy load as a clutch also wears out quite a bit. You can, of course, drive without a clutch - engage first gear and start on the fly, then change gears at the moment you release the gas (synchronizers in the gearbox were clearly invented for this). However, there is little pleasure from such a ride, and it does not add health to the car. So take care of the clutch, it’s a necessary thing.

How to save your clutch

In order for the clutch to last as long as possible, you must adhere to the following rules: at traffic lights and in traffic jams, turn off the speed and take your foot off the clutch pedal, when making shifts, release the gas pedal, do not move away abruptly, when the car is coasting, put the variable gear lever in neutral position and remove your foot from the clutch pedal, try not to use the car off-road or as a tow vehicle.

If you neglect these rules, then replacing the driven disc, and possibly the entire clutch, may be required much earlier. To check the wear of the driven disk, it is necessary to sharply press the accelerator in direct gear. If the engine “roars”, and the car is reluctant to accelerate, and a specific burning smell is felt, then this is the first sign that it is time to think about replacing the driven disk. Typically, once a clutch is burned, it will wear out completely within a couple of weeks.

Clutch burnt out: how to get to the service center?

In the case of an automatic machine, you can only get to the service station using a tow truck. Electronics may simply not allow you to continue driving. Therefore, let's consider the situation on a manual transmission. So, if the clutch burns out, how to get there? Remembering the school physics course, it’s easy to guess that to start without slipping the disk we need a minimum torque. Naturally, the first speed gear ratios will not allow us to do this. By turning on first gear, the car will stand still. Therefore, you need to start from second, and sometimes even third gear.

Thus, the friction force will be as low as possible, and the car will be able to start moving without the disc slipping. If necessary, you can switch to a higher gear. To do this, just develop the required speed and turn on the speed. But in order to switch back to a lower one, you cannot do without re-gasping. To do this, switch the lever to the neutral position and raise the speed above three thousand. Next we turn on the lower gear.