Shafts and axles of machines

Every machine, almost every device, has rotating parts: wheels, pulleys, steering wheels, levers. So that they can rotate, they are attached to other, at first glance, very simple parts - axles or shafts. What is the difference between a shaft and an axle?Think of a heavy railroad car. It is installed on 2 running trolleys; 8 pairs of wheels of these carts roll freely on steel rails. The thick, durable axles on which the wheels are mounted serve only as a support for them and do not transfer any force from one wheel to the other. In this case, the axle can rotate together with the wheels, like a carriage, or it can be fixed motionless, like a bicycle. The axle usually has supports at both ends. If the axle is fixed only at one end, and a wheel is installed at the other, it is called a semi-axle. The front wheels of the car are mounted on such axle shafts. This allows the car to make sharp turns.

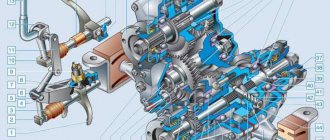

Shafts’ “responsibilities” are much more complicated: they not only support rotating parts, but, most importantly, transmit rotating forces from one part of the mechanism to another (see Mechanism).

For example, all engines do not have axles, but shafts that connect to other parts of the machine and transmit movement to them. Such shafts are called main shafts. Sometimes shafts connect the engine directly to the working part of the machine. So, ships have a shaft, at the end of which a propeller is installed. A propeller is mounted on the shaft of a piston aircraft engine.

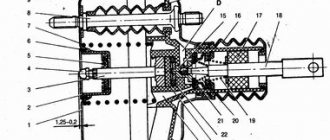

There are shafts that convert the translational motion of, say, engine pistons, into rotational motion, for example, the wheels of a self-propelled car (through a gear system) - these are the crankshafts of piston internal combustion engines. Shafts with cams mounted on them are called cam shafts. On the contrary, they convert rotational motion into translational motion. They can be found in automatic metal-cutting machines - they control the operation of the machine.

Transfer, or transmission, shafts transmit rotation from one part of the machine to another, or from one engine to several machines, etc. They can be made of solid metal or pipe. And sometimes a flexible metal cable is used as a shaft, as, for example, in a drill used to drill teeth.

All rotating axes and shafts are installed in the stationary parts of the mechanisms using special supports - bearings. In a car, you will find almost all types of axles and shafts that we mentioned.

What the professionals say

and the largest tire manufacturers recommend replacing four wheels at once. But if only a pair of damaged or heavily worn tires requires replacement, then you need to install a new pair on the rear axle.

The question of which axle to choose for more “fresh” tires also arises during seasonal tire fitting. In 99% of cases, a car service center offers to install tires in better condition or new tires on the driving axle of the car - and they are fundamentally mistaken if the car has front-wheel drive, or they accidentally guess if the car has rear-wheel drive. This happens because there used to be an opinion: tires in better condition or new tires should be installed on the drive axle of the car, depending on the type of drive, front or rear.

However, tests by tire manufacturers and leading automobile magazines refute this version. Tests show that new tires or tires in better condition should be installed only on the rear axle, regardless of the car's drive - front, rear or all-wheel drive. And all this for safety in unexpected and difficult situations on the road, for example during sudden braking or sharp turns.

Tests show that it is much easier to control the front axle than the rear, because the front axle has a steering wheel, which makes it much easier to correct drift.

Installing an additional axle on a vehicle

The latest changes by the Federal Road Service of Russia, in the resolution on weight standards and axle loads of freight vehicles, have put carriers at a disadvantage. A vehicle, which until recently could legally transport up to 30 tons, today already falls under non-compliance with this regulation, and even a vehicle with a load of up to 20 tons is already illegal. You can view the Resolution of the Federal Road Service of Russia “On Amendments to Certain Acts of the Government of the Russian Federation on the Transportation of Heavy Loads” here.

The amounts of fines for non-compliance with these standards are astonishing with their 6-digit values and are sometimes imposed three times - first of all on the carrier company, represented by the director of the company, also on the truck driver and even the mechanic.

If your vehicle does not fall under the new approved requirements for the weight of the road train and axle loads, and will bring you significant losses in the form of permanent fines from RosTransnadzor and the Cargo Auto Inspectorate, we offer you a solution, a profitable, proven and reasonable alternative: installing an additional axle on a semi-trailer . tractor , single truck , replacement of the rear bogie, from single-axle to double-axle, installation of a drawbridge, both single and twin. We can create almost any options for your truck, even an 8-axle wheel arrangement, in the tractor + semi-trailer scheme.

In any case, this conversion:

- will save you from catastrophic fines for overloading;

- will significantly increase the transportability of your vehicles;

- will increase the volume of your transportation;

- and will directly proportionally increase the profit of your company as a whole;

Service specialists constantly undergo training and professional development. We will be able to carry out the modernization of your vehicle at a high professional level and on time. Our service center has all the certificates, conditions and necessary equipment to carry out repairs of any complexity and maintenance of trucks, tractors, semi-trailers. We guarantee high quality of the repairs performed. Our service center uses only high-quality consumables and lubricants, as well as high-quality spare parts from well-known manufacturers.

Our advantages:

- experience in assembling new International 9800 cars

- production of low-load semi-trailers, container carriers and timber carriers "Goodwill"

- more than 20 years of successful experience in repairing trucks;

- affordable prices and bonus programs;

- strict quality control of all work performed;

- modern repair base, including all necessary service equipment;

- use of consumables only from well-known manufacturers;

- repairs in the shortest possible time with the highest possible quality of work performed;

- consultation with a service specialist on all operations performed and their necessity;

- wide selection of original spare parts and their analogues;

- provision of a full repair report and warranty for it (the period depends on the type of work performed).

| Type of work | Estimated cost | Deadlines |

| Installation of a stationary axis | 50,000 rub. | 2-4 working days |

| Installing a lift axle | From 65,000 rub. | 4-8 working days |

Our works

Service center Address: St. Petersburg 196608, Pushkin, st. Avtomobilnaya, 4, lit. AZ Telephone, (free call in Russia) E-mail Opening hours: from 9-00 to 21-00 Mon-Sat, Sunday – closed.

We are waiting for you at our service center!