06.09.2015

Replacing engine mounts on a VAZ 2110 is a very important and responsible procedure. If necessary, it should be carried out as early as possible, before a problem with seemingly small parts leads to vibration along the way and, as a result, rapid wear of the main elements of the transmission, as well as global engine breakdowns.

What is needed for repairs

First, you need to determine which support on the VAZ 2110 engine should be changed (if you do not want to change all the damper mounts at once). To do this, you need to do an independent inspection of these parts. Sometimes, the power plant seems to be tilted horizontally on one side or tilted along the central axis of the car. This is the first sign to replace the damper mounts.

Locksmith kit

Rolling jack

A couple of short boards

Angle grinder (grinder)

Two cushions (side) secure the engine to the left and right side members in the engine compartment. And one (rear) fixes the motor to the bottom. Therefore, it is necessary to lift the machine on a lift or install it on a viewing hole. The wear is immediately visible. The rubber has tears and core failure. Depending on the result of visual diagnostics, you should purchase the required number of parts for installation.

You will need a tool. In most cases, a standard locksmith set consisting of open-end and box-end wrenches with heads will be sufficient. In addition, to replace engine mounts on a VAZ 2110 you will need a rolling jack and a pair of short boards. It is advisable to have electricity and a cutting machine with a disc, since you may have to cut off the mounting bolts.

Helpful information! A couple of hours before repairs, it is strongly recommended to apply universal lubricant “Liquid Key” to the threaded connections. Damper supports are changed very rarely, therefore, unscrewing them without prior preparation is quite difficult.

How to check that the engine mounts are in good condition?

Before making a replacement, you need to make sure whether the vibration is really due to them.

Interior comfort depends not only on the presence, as many believe, but also largely on the correct implementation of vibration isolation. However, even if you have both, you may experience discomfort caused by problems associated with engine vibration.

Vibration can occur due to (), as well as as a result of damage to engine fasteners. Owners of VAZs (especially) often complain about a strange knocking noise in the engine compartment, which appears and disappears during acceleration or while driving over bumps.

Replacing the left engine mount of a VAZ 2110

Place the car on a level and solid surface. Disconnect the negative terminal from the battery. Remove the crankcase protection. We place a jack under the engine, and use a piece of board (as a spacer) to lift the engine. The power plant is suspended in this way and the supports do not experience any load.

Next, we perform the following steps:

- Unscrew the nut of the central stud (15 mm wrench);

- unscrew the two fixing bolts of the protective cover (13mm wrench);

- under the bracket, unscrew the 3 bolts that connect it to the spar (17 mm wrench);

- then, we take out the worn-out pillow;

- We replace the damper part with a new one and assemble the structure in the reverse order.

On a note! Spare parts from imported suspension manufacturers, such as: Lemferder, SWAG, RUVILLE, SKF, can provide high-quality and long-lasting performance. If they are not in the store, they can be delivered to order.

Step-by-step replacement process

Depending on which support has failed, we replace it.

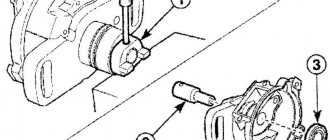

Right pillow

In order to unscrew the engine mount on the right side, we perform the following procedure:

- Remove the top nut on the cushion.

- Then two bolts that secure it to the bracket.

- Next, under the wheel arch, remove the bolts securing them to the side member.

- Remove the old element and install the new one in the reverse order of removal.

New right engine mount

Left pillow

- As in the case with the right pillow, remove the upper nut.

- Then unscrew the two bolts on the sides and remove the pillow.

- Remove the bottom washer from the stud.

- Install the new pillow in the reverse order.

Lower front airbag

- Using a wrench, unscrew the two bolts one by one.

- The sequence doesn't matter. Carry out dismantling depending on your convenience.

- We dismantle the old pillow and install a new one.

- If the inspection holes do not line up during installation, the engine must be raised slightly. You can use a jack for this.

Upper front airbag

This is what the new upper engine mount looks like

- Using the key set to “17”, unscrew the bolt securing the support to the body.

If the bolt does not come off, you can use WD-40.

We replace the old pillow with a new one.

Installing a new pillow

Please note that during this work, it is strictly forbidden to dismantle all the cushions at once, since in this case, the engine will simply have nothing to support it. Replacement should be done strictly one by one, starting with one of the four supports. Also, for the most reliable fixation, you can put wooden supports or a jack under the engine.

Malfunctions

You can tell that the engine mounts are out of order by the increase in vibrations emanating from the engine to the body. When it operates in a stable mode, and the body begins to vibrate and rattle, transmitting everything to the pedals, instrument panel and steering wheel, you can be sure that the engine mounts are faulty.

Also, wear of the pillows is often observed when starting the engine and turning it off. So, if there is a lot of wear, a noise may be heard about the contact of engine elements and the metal supports of the cushion.

Functionality check

Before you start replacing pillows, you should make sure the old ones are working. Because it may not be necessary to change them all at once.

First of all, with the engine running, inspect the condition of the airbags:

- For the presence of cracks.

- To maintain elasticity.

- Check for play in connections.

If such reasons are not observed on a certain pillow, then it does not require replacement. And if they are found, then there is no point in delaying replacement, since constant vibration can not only significantly reduce the comfort of driving a car, but also lead to negative consequences in the operation of the engine and gearbox.

Replacing the right engine mount of a VAZ 2110

Place the jack under the box. We hang the engine and remove the load from the cushion. Completely disconnect the battery and remove it (this will be more convenient).

Next, we move in the following sequence:

- Unscrew the nut of the central stud (15 mm wrench);

- Unscrew two bolts (13 mm wrench);

- We take out the central pin (you will have to loosen the jack a little);

- We take out the support bracket and replace the pillow with a new one;

- We insert the new support into place and raise the engine;

- We tighten the damper assembly with the bolts in the reverse order.

On a note! The support mounting areas on the side members may be in poor condition (rust). In order to extend their “life,” you should cover the damaged area with Movil immediately before installing the bracket.

Replacing the front upper support

This support is only available on 12 models. It’s not on the “tens”. But some craftsmen can strengthen it there. In this case, removing the pillow will be similar. The work consists of several stages:

- Use a “17” wrench to unscrew the bolt securing the support rod to the body of your car. In this case, the nut may fall out of the box. Hold it;

- Remove the nut and bolt;

- Next, the bolt securing the rod to the engine is unscrewed. To do this you will need 2 keys “15”;

- The bolt is also removed;

- All that remains is to remove the bar.

Installation is in the reverse order. There is one small nuance. When installing, do not immediately tighten the threaded connections. First, tighten all the bolts, and only then tighten them. It is better to start from the place of attachment to the power unit.

Replacing the rear engine mount of a VAZ 2110

If, when dismantling/installing the left and right supports, the work was carried out in the engine compartment, then to remove the rear damper you will have to crawl under the car. It’s good if there is an inspection hole in the garage, since the ground clearance of the “ten” is quite low and it’s very difficult to crawl up on your belly.

The replacement process looks like this:

- We install a jack under the box and hang the rear part of the engine;

- Unscrew the two support nuts from the body (17 mm wrench);

- Using 2 19 mm keys, unscrew the support mount from the gearbox;

- We remove the support from the seats and take it out from under the car;

- We take out the bolt and replace the damper with a new element (a vice may be needed);

- We return the knot to its place and tighten it;

- We lower the engine with a jack and install the crankcase protection.

After you have managed to change all the engine mounts on the VAZ 2110, the engine should take a level position. You should start the engine and carefully observe the vibration. It should be minimal. This means that the repair was carried out correctly.

Replacing the rear support

This pillow requires a little more attention. Since it is located near the box, which makes it somewhat difficult to remove.

- The work is carried out as follows: We install a jack under the gearbox;

- Using the “17” head, unscrew a pair of nuts securing the socket from the support to the body;

- Using “19” keys, you need to unscrew the screws securing the rear support to the gearbox. There are only 2 of them;

- We remove the support along with the socket. We clamp the socket with a vice and unscrew the screw with a “19” key.

Features of replacing engine mounts with a 16-valve engine

The main difference in the mounting of the 16-valve engine is the absence of a rear lower support. The engine is attached with a rear support from above to the number plate of the body. Another additional damper bracket is located at the bottom front. It connects the motor and the lower beam of the radiator (TV) frame. These parts are called “guitar”. After hanging the engine with a jack, they change simply.

Replacing engine mounts on VAZ-2110, 2111, 2112

A cushion is an element of an engine support that serves to secure the engine to the car body. The support is a rubber-metal structure consisting of a steel body and a thick rubber pad.

The main role of the pillow is to dampen vibration coming from the motor.

On VAZ 2110 cars, eight-valve engines are attached to the body by 3 supports (two side and rear), and sixteen-valve engines are attached to 4 (two side, lower front and upper front).

Changing pillows

Replacing the right pillow

- Unscrew the top nut of the pillow.

Remove the upper nut of the pillow

- Then the bolts that secure the cushion to the bracket.

Unscrew the pillow bolts

- We go from below, under the wheel arch we unscrew the bolts that secure the bracket to the spar.

Unscrew the bracket mounting bolts

- Remove the bracket. We install a new pillow and reassemble it in the reverse order.

Replacing the left pillow

- As in the first case, unscrew the top nut. We are preparing a support for the gearbox in advance; the engine will be lowered.

Unscrew the left airbag nut

- We lower the engine onto the support we prepared in advance. Now you can pull out the upper support washer.

Pulled out the top washer

- Now unscrew the bolts securing the pillow.

Unscrew the bolts securing the pillow

Old pillow removed

- Remove the washer with the pin.

Removing the washer with the pin.

- We replace the old pillow with a new one and reassemble it in the reverse order.

Replacing the rear cushion

- Using a socket, unscrew the nuts securing the cushion to the body.

Unscrew the nuts securing the pillow.

- Then the mounting bolts to the gearbox.

We unscrew the bolts securing the cushion to the gearbox.

- We take out the pillow.

Rear cushions can be sold assembled with or without a bracket. If you purchased a pillow without a bracket, move the bracket from the old pillow .

We move the new pillow onto the bracket:

- We clamp the bracket in a vice (See photo below);

- Unscrew the nut and remove the old pillow;

- We put the new cushion on the bracket and tighten the nut.

We remove the bracket from the old pillow and replace it with the new one.

Reinstall the pillow in the reverse order.

Airbag malfunctions

You can tell that the airbags have become unusable by the amount of engine vibration. If it operates in normal mode, and the body begins to rattle, transmitting vibration to the steering rack, pedal block, and instrument panel, you can be sure that the reason for this is the wear of the pillows.

The greatest vibration is usually observed when the engine starts, as well as when it is turned off. When the rubber cushions are completely worn out, a knocking noise may appear caused by the contact of the engine elements and its supports.

To be more convincing, start the engine, open the hood and visually inspect the engine mounts and the cushions themselves. Place your palm on the motor and feel how much it vibrates.

The causes of failure of engine mounts can be:

- deformation due to spent life, mechanical or temperature effects;

- loss of elasticity due to “aging” of rubber and temperature changes;

- delamination or cracking caused by exposure to chemically active liquids.

Diagnostics of pillow wear

Wear of the pillows manifests itself primarily in the form of increased vibration of the power unit.

If the engine runs smoothly, but the vibration has noticeably increased, you can confidently diagnose wear on the engine fasteners.

As a rule, the peak of vibration is felt when the engine is turned on and off - the car rattles, and the steering wheel seems to be trying to escape from the driver’s hands. In the case when the wear of the pillows has reached critical levels, along with vibration, a characteristic metallic grinding sound appears, arising from the contact of structural elements of the body and the engine.

In order to make sure that the increased vibration is caused by wear of the cushions, you should inspect the mounting supports and cushions while the engine is running. You can determine the strength of vibration by placing your palm on the motor.

After diagnosing the malfunction, it is necessary to replace worn out cushions as soon as possible, since in addition to affecting comfort, increased vibration can lead to serious damage and deformation of body and engine elements.

See our material for all the pros and cons

What is a car VIN code and why is it needed - see

Note that in cases where the steel elements of the supports are not worn out, you can limit yourself to replacing the rubber part of the structure.

Do I need to change

There are no recommendations for replacing pillows depending on their service life, but once you determine that they are faulty, you should not delay replacing them. Vibration processes can not only worsen the comfort of the driver and passengers, but also lead to destructive processes in the engine or gearbox itself.

Having decided to repair the engine mounting elements, you need to decide whether you will change the cushions themselves or the mounts assemblies. In principle, if the metal support itself is not damaged, it can be left, replacing only the pillow.

The price of a set of pillows for a VAZ 2110 costs around 1,300 rubles. The cost of a complete set of supports is about 2,500 rubles.

For the work of replacing engine mounts or mounts at a service station, you will be charged at least 300 rubles for each.

For eight-valve engines

- Prepare the car for repair: place it on a flat surface, place stops under the rear wheels, remove the engine protection.

- Unscrew the generator belt tensioner bolt and remove the belt (key 13).

- Place the jack under the engine, place a thick wooden beam or board under its upper part. Raise the engine to remove the load on its mounts.

- Unscrew the nut of the central fastening of the right pillow (15 wrench).

- Unscrew the bolts securing the pillow to the bracket (key 13).

- From the bottom side of the right arch, unscrew the 3 bolts securing the bracket to the spar (17 key).

- Remove the bracket and replace the old cushion with a new one.

- Carry out installation in reverse order.

- Move the jack under the gearbox and lift it up.

- Unscrew the nut of the central fastening of the left pillow (15 wrench).

- Unscrew the two bolts securing the support and remove it (key 13).

- Replace it and reassemble the structure in reverse order.

- Unscrew the two 17 nuts securing the cushion to the body, and then two more nuts securing it to the gearbox (removal and replacement of the rear support is carried out from the bottom of the car).

- Remove the rear support.

- Unscrew the nut securing the pillow to the bracket (19mm wrench). Remove the old pillow and install a new one.

- Install the rear support in reverse order.

For sixteen-valve engines

Removing and replacing side airbags is done in the same way as for 8-valve engines.

Work to replace the front lower airbag is carried out from underneath the machine.

- Unscrew the bolt securing the front lower support rod to the front suspension cross member (15 wrench).

- Unscrew the nut of the bolt fixing the support to the engine bracket (2 wrenches x 15). Remove the bolt.

- Remove the support, replace the pillow or the entire structure.

- Carry out installation in reverse order.

- In the engine compartment, unscrew the bolt securing the upper front support to the body, holding its nut with your hand (17 wrench).

- Remove the bolt and nut.

- Unscrew the bolt securing the front upper support to the engine bracket (15mm wrench). Remove the bolt and nut.

- Remove the support, replace the pillow or the entire structure.

- Install it in reverse order.

Replacing the left support

To do this, install a jack under the gearbox and raise it slightly:

- In this position, using a “15” wrench, you can unscrew the main nut, after which the box lowers slightly;

- Using a “13” spanner, unscrew the 2 nuts securing the support to the body and remove it;

- Next, the limiter from below is removed along with the pin.

The pillow limiter at the top is removed;

After that, we install a new pillow in place.

Design and purpose of tens engine mounts

Over the years, vast practical experience has been accumulated on the topic of how to change engine mounts on a VAZ 2110, and videos of repair processes can also be found in abundance. However, few people pay attention to the features of the part. And, it must be said, it is in vain, because such knowledge will help to accurately determine the source of vibration and purchase the necessary spare part for repair.

The main purpose of the engine support is to reduce the level of vibration transmitted from the power unit to the car body. The rubber-metal structure consists of a steel base with a thick rubber cushion. The device has proven itself well, since it is quite reliable and is worth the money.

The eight-valve Lada 2110 engines are attached to the body at three points: right, left and rear. The side supports connect the body to the engine block through through holes. The rear support is attached with two bolts to the gearbox, and two nuts to the body. The importance of this damper part is very significant - it prevents longitudinal vibrations of the internal combustion engine during braking and acceleration.

Replacing structural engine mounts: theory and practice

The engine mount is a steel support on a rubber cushion. Despite the fact that rubber is a very reliable material, after a long mileage it is better to update the fasteners, which will extend the life of the engine. A characteristic manifestation of wear on the cushions is an unpleasant rattling sound; the car begins to behave like a tin can filled with coins. If such manifestations occur, you need to change the rubber cushions.

You can check the correctness of the assumption about wear again by opening the hood. Place your hand on the running engine. If the rattling is intense, be sure to change the pillows. The conclusion is obvious, since rubber cushions must not only reliably hold, but also absorb vibrations of the operating unit. If this effect does not exist, this structural element is significantly worn out and does not perform its functions.

When should you change the power unit mounts on a VAZ 2110: signs and reasons

Before you change the engine mounts of a VAZ 2110 car and watch a video of this process, you need to study the signs that indicate a breakdown of the rubber-metal mounts. The main symptoms characterizing problems with damper units:

- Vibrations transmitted to the steering wheel and pedal unit when idling.

- Extraneous noise in the cabin when moving on an uneven surface.

- A characteristic knocking sound in the engine compartment during acceleration and braking.

When drawing conclusions after your observations, you should not confuse vibrations on the steering wheel during braking, which are associated with defects in the brake discs or pads. To be more convincing, you need to open the hood and inspect the power unit supports. If you place your palm on a running internal combustion engine, you can feel changes in its operation.

Many years of experience in operating the Lada 2110 allows us to assert that the reasons for the failure of damper cushions are the following factors:

- Deformation phenomena on the rubber support due to mechanical and temperature influences, as well as due to exhausted service life.

- Cracking and delamination of rubber from exposure to chemically active components.

- Loss of elasticity caused by temperature changes.

Premature failure of the damper support can be caused by the owner’s excessive enthusiasm for such extreme techniques as sudden starts and emergency braking. Suspension parts are already subject to serious stress while driving, and a sporty driving style further increases the risk of their failure.

Reasons for failure

Among all the reasons for the failure of engine mounts, the most basic can be identified:

- Spent life of engine mounts due to mechanical impact.

- Wear of rubber elements due to constant changes in ambient temperatures.

Before you go to the store, you should determine whether it is worth changing only the cushions or the entire support assembly. Depending on the condition of the metal supports and the absence of damage on it, you can replace only its rubberized component.

- The price of a set of pillows for a 16-valve VAZ-2112 is about 1,500 rubles, and the assembled supports are 3,000 rubles.

- Work on replacing pillows in car services varies within 500 rubles per piece, however, we believe that this is a waste of money, and we suggest that you carry out this work yourself, since no special skills are required for this.

We repair competently: how to change the damper mounts of a VAZ 2110 engine and video of work processes

Replacing bearings is, of course, more troublesome than adjusting the clutch . but if you have the skills and a minimum set of tools, it is quite feasible without the help of car service specialists. To work, you will need a jack and a set of wrenches; you also need to take WD-40 fluid in advance - it is possible that the connecting elements are covered with rust. To perform a cycle of work, you need an inspection hole or a lift.

Replacing the right damper support

Before changing the right engine mount of a VAZ 2110 car following the video example, you should install wheel chocks and also disconnect the negative terminal from the battery. The further process is carried out according to the following scheme:

- Loosen the generator fasteners with a 13mm wrench and remove the belt drive.

- Loosen the tensioner bolt.

- Jack up the right side of the car.

- Using a 15mm wrench, unscrew the nut securing the support.

- Using a 13mm wrench, unscrew the two bolts securing the support to the bracket.

- Using a 17mm socket, unscrew the three bolts securing the bracket to the right side member.

- Remove the bracket and install the new support in the reverse order.

Replacing the left damper support

The procedure for changing the engine damper on the left side of the car is performed in the following order:

- Remove the car crankcase protection.

- Place a jack under the car in the area of the gearbox, place a wooden beam and lift the car, removing the load from the support.

- Using a 15mm socket and a wrench, unscrew the support pin fasteners.

- Release the support stop.

- Lower the jack slightly to freely remove the support pin.

- Using a 13mm socket, remove the fasteners of the engine support to the body.

- Pull the support towards the motor.

- Remove the lower support stop and install the new part in the reverse order.

- Remove the engine crankcase protection.

- Using a 17mm socket, unscrew the two nuts securing the support to the car body.

- Using two 19mm wrenches, unscrew the two bolts securing the gearbox and remove the support.

- Clamp the removed bracket in a vice and use a 19mm wrench to unscrew the bolt securing the support.

- Remove the bolt and install a new rubber support in the bracket.

- Assembly of the unit is performed in the reverse order while maintaining the perpendicularity of the mating planes.

Replacing the rear damper mount

Reading how to change the rear engine mounts on a VAZ 2110 and watching the video is half the battle. It is important to strictly adhere to the order of repair work:

Based on practical experience, it can be argued that the process of replacing the damper supports of the power unit on the “ten” is not particularly difficult. Usually, after repair, vibrations disappear, but if everything remains unchanged, then the solution to the problem may lie in a different plane. It makes sense then to look for a problem in the suspension or in the CV joint components.

Comfort in the cabin is one of the main tasks that every third car owner deals with. And it's not just about the car's sound insulation and its quality.

The source of extraneous sounds may be vibration of the power unit. In this case, the cause of additional noise may be detonation or engine malfunctions. In addition, problems related to the fastening of the unit itself cannot be ruled out.

In the latter case, knocks and other sounds coming from the engine compartment appear irregularly - when accelerating or when driving on uneven sections of the road.

So, if during a trip you are bothered by a strong knocking noise from the engine area, the reasons may be the following:

• Failure of suspension elements.

• Poor quality of the road.

• Faulty VAZ-2110 engine mounts.

We will pay special attention to the last reason.

Replacing the right support

This job is not difficult. But to remove this particular support, you will have to perform quite a lot of additional manipulations.

So, let's start the repair:

- First, remove the belt from the generator, it will interfere. Next, the attachment of the “genes” to the motor is slightly loosened;

- We place a jack at the bottom of the engine crankcase and lift it;

- Unscrew the nut securing the pillow, use the “15” wrench;

- Remove the 2 screws securing the pillow to the bracket;

- All that remains is to unscrew the 3 bolts from the spar and remove the bracket;

- Remove the old cushion and install the new one.

Assembly is carried out in reverse order.

Conclusion

. The shock-absorbing elements of the power unit also sometimes require replacement. Although, on domestic cars they are quite reliable. Replacing engine mounts on VAZ 2110 and 2112 is not a difficult job. Even a novice motorist can handle this.

What are motor mounts, and what function do they serve?

In fact, the engine mount is a regular gasket located between the body part and the engine itself. We didn't spend much time developing and optimizing this design. The device looked like a piece of rubber with special fastenings on the sides. Previously, cars had rear-wheel drive, and the front-wheel drive version appeared only in the mid-80s of the last century.

At the present stage, more attention is paid to engine mountings. They come in two types - hydraulic and rubber-metal. The first type of device is more efficient, but due to the high cost of production and the complexity of the design, it is used only on expensive machines.

Most often, the engine of a car equipped with front-wheel drive is fixed using 4–5 supports, two of which are located on the gearbox, and another 2–3 on the power unit. In this case, the engine and gearbox have a rigid connection.

Sixteen-valve transverse unit VAZ-2112

The side airbags of the 16-valve VAZ engine change in the same way as on its eight-valve version.

The lower front airbag is dismantled by unscrewing the two bolts securing it. First, you should slightly raise the engine using a jack or a special lift. After removing the old part, the position of the power unit may change slightly. In this case, the holes for the bolts on the support and in the places where it is attached will no longer coincide. You should raise or lower the motor a little more, in this way achieving a clear alignment of the holes.

The upper support located near the right “glass” is replaced in a similar way. If, after unscrewing the fixing nuts, it is not possible to move and remove the element, it is necessary to raise the “engine” another 1-2 cm, which will allow the existing load to be removed from the support. The new pillow is installed in the reverse order. To facilitate installation, it is permissible to treat the seats with WD-40 type lubricant.

Note: dismantling all engine mounts cannot be done at the same time. After such actions, the power unit will simply fall to the ground. It will be extremely difficult to install it back. Replacement of the front engine mount, rear mount, and side supports should be done one after the other.

Replacing airbags on “tens” with an 8-valve engine

First of all, let's look at how to change the engine mount on a car with an 8-valve engine. The algorithm of actions is as follows:

• Place the vehicle on a flat surface and secure it by placing stands under the rear wheels.

• Remove the protection from the power unit.

• Tighten the bolt that provides belt tension, and then remove the belt using a thirteen key.

• Place a jack under the engine, placing a wooden object between it and the metal. Now raise the engine to unload the cushions.

• Unscrew the fastening nut holding the pillow on the right. Here you will need a key for “fifteen”.

• Tighten the fixing bolts that hold the assembly to the bracket (use a thirteen wrench).

• From the bottom of the right arch, unscrew the three mounting bolts holding the mount to the side member.

• Remove the bracket and install a new pillow.

• Return all parts using the reverse algorithm.

After completing the work described above, move the jack under the gearbox and lift it.

Tighten the support fixing nut on the left with a wrench by about fifteen, and then unscrew a couple of support fixing bolts, and then remove the cushion. Now change the support on the left side.

Replacing the rear cushion - in detail

• Take the key to “seventeen” and unscrew a couple of nuts holding the pillow to the body.

• Tighten a couple more nuts securing the gearbox.

• Remove the rear support.

• Unscrew the nut that holds the support to the mount (you will need

key to "nineteen"). Replace the unit with a new one.

• Return the rear cushion to its place.

Replacing engine mounts on a VAZ-2110 equipped with a 16-valve engine is done as follows:

• Tighten the bolt that holds the airbag rod from below to the cross member using a fifteen-point wrench.

• Using a pair of "fifteen" wrenches, tighten the nut holding the support to the motor mount. After this, remove the bolt.

• Remove the support and then replace the cushion or the entire mechanism.

• Assemble the device using the reverse algorithm.

• Tighten the mounting bolt that holds the upper support. To avoid turning the nut, hold it by hand.

• Remove the cushion and replace it.

• Unscrew the fasteners holding the top cushion (use a key to “fifteen”), then replace the structure.

That's all . Replacement of VAZ-2110 engine mounts has been completed. At the same time, it is not difficult to do the work yourself. If you do not have the necessary skills and experience, contact a service station.

Replacing the front lower support

This support is also installed only on the “two-piece”. Its functions include additional mitigation of vibrations that occur during engine operation. Replace it as follows:

- First, remove the engine mudguard;

- Using a “15” wrench, unscrew the screw that secures the bar (front suspension cross member);

- To remove the rod from the front support mount, you will need 2 open-end wrenches “15”. After unscrewing the nut, the screw is removed;

- Remove the engine support.

Installation should not cause any difficulties. But, only if there are remaining supports in the proper places. To align the holes you need to slightly rock the engine.