Valve burnout is a problem that owners of domestic cars most often encounter. But it would be unfair to blame exclusively the products of the Russian automobile industry, since they are also found in foreign cars, even if they are far from new. But any valve malfunction, including burnout, can lead to very serious consequences, so every car owner simply needs to be able to recognize the signs of a burnt-out valve in a timely manner in order to be able to promptly correct what can still be fixed without unpleasant surprises.

Causes of the malfunction.

The symptoms of a burnt valve are to some extent similar to malfunctions that are completely unrelated to the car’s engine. That is why insufficiently experienced car owners can spend a lot of time and effort to repair and fix something that, in principle, was not broken. As a rule, they are the last to realize that the valve has failed.

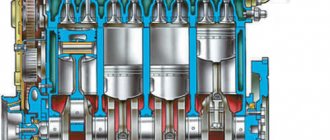

But despite all their apparent insignificance, the valves perform a very important function - they allow fuel to enter the combustion chamber and release burnt gases. That is, they are constantly in an aggressive environment - under the influence of gases and high temperatures.

It is natural that the metal from which the valve is made gradually deteriorates - the valve burns out.

Most often, the valve “flies” in very old cars, as well as in budget cars, when producing which the automaker chose price over quality. However, car owners themselves, without even realizing it, often provoke/accelerate the process of valve burnout, for example, by filling their car with fuel that is not suitable for it. But this, as they say, is a topic for a completely different article.

A high percentage of defective spare parts is a problem for the motorist

These are not the main reasons why valves burn out. The leading manufacturer of these parts conducted a small study, and the statistics were not happy - every fifth part that is produced breaks or burns out due to the human factor and defects. And even modern product quality control at factories does not guarantee that the part is free of any defects.

Another reason is metallurgical inhomogeneities that are included in the alloy. These irregularities make the valve weaker than it should be. In addition, there are manufacturing defects, namely forging. This leads to microcracks. Errors in the heat treatment process lead to changes in the dimensions of the product.

On the subject: Why did they choose red, yellow and green signals for the traffic lights?

Symptoms of a burnt valve.

As noted earlier, the symptoms of a burnt valve are very similar to the symptoms of a malfunctioning ignition system, so many people begin to repair it first. But the engine, despite all the repair work, continues to act up and malfunction. That’s when a frantic search begins for other possible causes in the engine and other systems, although it’s all about a banal valve.

The most important symptom of the indicated problem is engine tripping, when one or more cylinders stop functioning. This happens because a burnt-out valve, when fuel burns, begins to let gases through, which do not push the piston down, but directly exit into the manifold.

You can diagnose this malfunction without disassembling the engine by following a certain algorithm of actions:

- we check the ignition - the integrity of the wires, the functionality of the distributor, the ignition timing;

- we determine the problem cylinder - we pull off the high-voltage caps from the spark plugs, the engine will start to stall if the cylinder is working, or if the cylinder is faulty, the engine operation will remain unchanged;

- Let's measure the compression: it will most likely be slightly lower than the required 11 points, by the way, this may be an indicator of not only a valve malfunction, but also a piston group malfunction.

Now a few words about how, without disassembling the engine, you can determine what exactly you are dealing with - a malfunction of the valve or piston group.

- Turn on the ignition and remove the breather hose. Warm air should come out of it, or at least a little smoke. The smoke is dense, gray, smelling of exhaust - a sign of a malfunction of the piston group.

- Remove the spark plug from the problem cylinder. If the piston is damaged, the spark plug will be in oil, and if the valve is burnt out, it will be in normal condition.

- Remove the cylinder head and replace the damaged element. If the valve is changed, then it must be replaced, and all valve stem seals must be replaced along with it.

Fault localization

The most common and effective method for determining a burnt-out valve is compression measurements. If the results show low compression, then this is clearly a sign of burnout. But here you need to take into account a small nuance - using compression measurements it will not be possible to exclude CPG defects. Low compression is not only due to burnout. Various other defects can reduce it - for example, it could be broken rings. Therefore, if all the signs of a burnt valve are observed on a VAZ-2109 or on any other car, you will have to additionally diagnose the car.

The easiest way to help determine burnout after measurements is to pour a small amount of oil into the cylinder. Next, the compression is measured again. It should grow - this indicates that an oil film has been created. This is typical for a worn piston system. If the compression has not changed, then this is definitely a burnout. The way out of the situation is to replace the valves.

On topic: Reviews of Nissan Primera

Another diagnostic method is a visual inspection of the spark plug from the problematic combustion chamber. If there is no characteristic deposit on the spark plug, then this is a clear sign of burnt-out valves. In addition, air or smoke will come out of the breather.

Why do valves burn out?

Valves burnout occurs for various reasons. For engines that require periodic valve adjustment, valve burnout often occurs due to untimely adjustment. On engines with automatic adjustment of the specified gap, failure of hydraulic compensators also often leads to the valve burning out.

The main causes of engine valve burnout are:

- valves are tightly clamped;

- worn out;

- the valve stem itself is worn out;

- the engine runs on a lean mixture (especially if equipped);

The consequences of driving with a burnt-out valve are different, ranging from increased fuel consumption to burnout of the valve seat. In some cases, a burnt valve seat leads to the need to repair the seat or even completely replace the cylinder head.

A burnt-out valve can collapse at one moment, after which fragments of the valve fall into the engine cylinder. As a result, serious piston damage, defects or damage may occur. In the latter case, there is a risk that a large piece of the burnt valve will pierce the engine cylinder block, which is the actual destruction of not only the cylinder head and piston group, but also the cylinder block. In such a situation, prolonged operation of the engine with a burnt-out valve may lead to the need to replace the entire engine.

Why is this happening?

This malfunction occurs for various reasons. Moreover, even owners of new cars are not insured against valve burnout. A similar problem also exists on diesel engines. What are the ones on the VAZ-2110? The usual culprit is tight saddles. All this will be accompanied by the characteristic “tractor” rumble of the engine. must comply with the standard. If this is not the case, there is a risk of valve burnout.

A similar problem can happen on modern engines. The reason for this is non-functioning hydraulic compensators. If oil does not pass through them, the gap will be set incorrectly. Among other signs, it is worth noting an incorrectly configured HBO (if one is installed on the car). When driving with a mixture that is too lean, there is a risk of burning out one or more valves.

Symptoms of a burnt valve

The main sign of burnt-out valves is a noticeable tripping of the engine in different operating modes. Also, in the case of a burnt-out valve, the engine loses a lot of power and fuel consumption increases noticeably. A certain difficulty in diagnosing burnt-out valves without disassembling the engine and removing the cylinder head is that the engine can trip for various reasons:

- wear, reduction;

- problems with, malfunctions, etc.;

- problems in, malfunction of injection nozzles;

Determining valve burnout without removing the cylinder head

The first step is to determine which cylinder is not working. The testing methods are in many ways similar to diagnosing faulty spark plugs. To check, you should start the engine, after which, with the engine running at idle speed, you will need to remove the caps from the spark plugs one by one.

After removing each spark plug cap, you need to carefully monitor the idle speed and the overall stability of the engine. If the engine starts to rev more strongly or stall, then the cylinder from which the cap was removed is working. If after removing the cap the engine operation does not change or the speed changes only slightly, then the problem cylinder has been detected.

Then you need to unscrew the spark plug on the inoperative cylinder and replace it with a known good one, and also check the high-voltage armored wire of this cylinder for functionality. It would also be a good idea to check the ignition coil, etc. Subsequent starting of the engine will show whether the problem lies in the elements of the vehicle’s ignition system or whether further diagnostics are necessary.

If the nature of the engine’s operation does not change after installing the working spark plug, replacing the high-voltage wire and checking other components of the ignition system (the engine continues to rev), then there is a high probability of more serious breakdowns:

- valve burnout;

- CPG malfunctions;

Burnout of the valves means that compression in the cylinder is reduced due to a violation of the tightness of the combustion chamber (leakage during the fit of the intake or exhaust valve, destruction of the disc and/or valve seat). Wear of the cylinder-piston group and piston breakage also lead to low compression in the problem cylinder. Also, the cylinder may not work due to stuck or broken piston rings.

Now it is necessary to localize the malfunction, that is, to accurately determine the burnout of the valve or identify problems with the CPG. The most common way to determine burnt valves is to measure the compression in the cylinders.

Low compression clearly indicates a malfunction, but one caveat should be taken into account. It will not be possible to establish a burnt-out valve and rule out problems with the CPG only based on the compression indicator. The fact is that compression in the engine can decrease both as a result of a burnt-out valve, and due to broken piston rings, as well as a number of other defects. For this reason, in parallel with the compression measurement, additional engine diagnostics should be carried out.

- The easiest way to determine valve burnout after you have measured the compression in the cylinders is to pour several “cubes” of engine oil through the spark plug well. Then the compression must be measured again. An increase in compression in the cylinder after adding oil will indicate that an oil film has formed, acting as a “seal”. This phenomenon is typical in the case of piston wear. If the compression indicator has not changed, it means that the valve has burned out, since the oil in the cylinder in this case will not affect the compression in any way.

- Also, to determine whether the valves are burned out, you should inspect the spark plug on the problem cylinder. A clear sign of valve burnout is that the spark plug is completely dry, that is, it does not have a characteristic oil deposit. There may also be smoke or air coming out of the engine breather. The intensity of smoke production directly depends on the degree of wear of the CPG.

As for breakdowns that are associated with the piston, in this case the spark plug is covered with oil, and the appearance of bluish smoke can be observed from the breather. Note that oil on a candle is an indirect sign. Even if the spark plug is dry or covered with a slight soot, but smoke comes from the breather, then this symptom indicates problems with the piston or piston rings. On new engines with low mileage, there is a high probability that.

Let us add that the appearance of engine oil that comes out through the breather also indicates a malfunction of the partitions between the piston rings. Taking into account the above, you can accurately determine why the compression in the engine has decreased, identify problems with the cylinder-piston group, or determine burnout of the timing valves.

Adviсe

Check the valve carefully when purchasing. Check the size standards and inspect the part for visible defects. Purchase spare parts only from certified points of sale from reputable manufacturers. The money saved on a cheap purchase will result in expensive repairs.

Check the valve clearances in the engine. Too short a distance is a common cause of overheating. Reduced clearance indicates wear of the valve seat. Install stiffer motor seats to prevent damage.

Article on the topic: Replacing the timing belt on a Hyundai Tussan 2.0 with your own hands

Let's sum it up

Let's start with the fact that the appearance of the first signs of valve burnout is a reason for immediate diagnosis of the engine. If the engine requires periodic valve adjustment, then this procedure must be carried out strictly according to the regulations. You should not wait for the moment when noise or knocking of valves appears.

On cars that run on gas, it is necessary to pay increased attention to the issue of valve adjustment. On such cars, it is advisable to adjust the valves every 10 thousand km. mileage, that is, in parallel with changing the oil during scheduled maintenance. The fact is that burnout of the exhaust valve in gas engines is much more common compared to gasoline.

The driver’s desire to save as much as possible on fuel after installing LPG is initially expressed in the fact that the owner asks the tuners to make the car economical. The technicians deplete the gas supply, as a result the engine noticeably loses power, but there is no significant reduction in gas consumption. The fact is that to maintain a dynamic driving pace, you have to press the accelerator more actively. At the same time, the lean mixture literally burns out the valves and seats with all the ensuing consequences. A high-quality LPG setup implies an almost complete absence of difference in throttle response when driving on gasoline or gas.

Burnout of valves is one of the quite common car engine malfunctions. Both intake and exhaust valves can burn out. In this case, to one degree or another, part of the working surface of the valve disc is destroyed.

The tightness of the combustion chamber during the compression stroke decreases, compression decreases, the necessary conditions for ignition of the fuel mixture are absent, and the cylinder stops working normally. As a result, the vehicle's performance deteriorates and the engine's service life decreases.

Signs of valve burnout

— The engine “troits” at idle.

— Slamming exhaust gases coming out of the muffler.

— Increased fuel consumption.

— Deterioration of vehicle dynamics.

At the same time, engine power and throttle response are greatly reduced.

the working surface of the valve disc is most often subject to destruction (burnout)

Causes of valve burnout

— Long-term driving on a lean fuel mixture.

— Long-term operation of the car with late ignition.

— The gaps in the valve mechanism are too small.

— Prolonged engine overheating.

— Use of low-quality fuel or engine oil.

— Low quality of spare parts (if the engine has been rebuilt).

How to determine if a valve is burnt out or not

— Compression measurement.

It is necessary to check the compression in the engine cylinders; in the cylinder where it is reduced, the valve may burn out. To finally verify this and eliminate wear on the piston rings (which also affects the amount of compression), pour 10-15 cubes of engine oil into the cylinder through the spark plug hole and measure the compression again. The compression readings in the suspicious cylinder are leveled off compared to the others - the piston rings are worn out (stuck, burnt, etc.), there is no 99 percent problem with the valves (in rare cases, cracks in the block or head).

More information about measuring compression and analyzing compression meter readings: .

— Blowing with compressed air.

We set the piston in the cylinder to top dead center, corresponding to the compression stroke. We direct a stream of compressed air from the compressor or pump into the spark plug hole of the cylinder. If the exhaust valve is burnt out, the air will go into the muffler, if the intake valve burns out, it will go into the carburetor.

Notes and additions

— In addition to burnout, similar symptoms are possible if other problems arise with the valves: severe carbon deposits on the valve plates, cavities and cavities on the working surface of the valve plates, too large thermal gaps in the valve drive. All of them lead to a loose fit of the valve plate to the seat in the head and, accordingly, disruption of the normal operation of the cylinder.

In any case, the fault can be eliminated only by removing the engine head and checking the valves. There are no other repair options.

It is useful for drivers to know all the symptoms and signs of a burnt valve. Owners of domestic cars often encounter this problem. This can also happen on other machines. Especially on not very new foreign cars, of which we have plenty. Valve problems can cause many problems. Including increased engine wear.

In addition, the symptoms make driving quite nervous. Which has a negative impact on the driver’s condition. In this regard, it is important to promptly identify this malfunction and eliminate it.

Why is there a problem?

The symptoms and signs of a burnt valve

are very similar to other types of faults. Moreover, many drivers do not believe in this particular malfunction until the very end and waste time on unnecessary actions.

Valves perform an important function. They allow fuel to enter the combustion chamber. And they release the burnt gases after finishing their work. As is clear from the described valves, they are constantly in aggressive conditions. They are exposed to gases and high temperatures. This leads to the destruction of the metal that makes up the valve. Gradually it burns out.

This happens especially often with old cars whose valves were made of not very good materials. Also, many people make this problem themselves. They fill their car with fuel that is not intended for it. As a result, increased combustion temperature leads to damage to these elements of the cylinder head (cylinder head).

The main sign of burnt valves is engine tripping. That is, one or more cylinders are not working. With this malfunction, the tightness of the combustion chamber is compromised. A burnt-out valve allows gases to pass through during fuel combustion. As a result, they do not push the piston down, but simply go directly into the manifold. This causes one cylinder to miss.

The driver notices exactly this in the form of engine tripping. Also a symptom of such a problem is, which is not surprising, because part of it simply flies into the atmosphere.

Signs

The symptoms of a burnt valve coincide one-to-one with a sign of a malfunction in the ignition system. Therefore, very often inexperienced mechanics begin to repair the ignition. At the same time, they change the distributor cap, install new spark plugs, set the ignition, but there is no result. The engine has been running every now and then and continues to do so. They, cursing the creators of cars, continue to look for the cause, without even realizing the true cause of the problem. Moreover, even those who guessed that the problem lies in the engine will only find out about the burnt-out valves after removing the cylinder head.

However, there is a way to diagnose this malfunction without disassembling the engine. The search for the cause must occur according to a certain algorithm:

- Ignition is checked

. Here you need to pay attention to the performance of the distributor, the correctness, integrity of the wires; - . They do this in the following way. One by one, they pull off the high-voltage caps from the spark plugs. If the cylinder is working, the engine will start to stall. The faulty one will not respond to such an action, and the operation of the engine will not change. This should be done carefully. The caps must be removed using insulated pliers;

- After that . Most likely, it will be slightly lower than the required 11 points. But this may be an indicator of both problems with the valves and a malfunction of the piston group.

Usually at this stage, car enthusiasts grab a set of keys and begin to enthusiastically rev up the engine. But there is a way to recognize the true cause of the malfunction without disassembling the engine. It is worth preparing the necessary parts and tools in advance. This is done as follows:

- First you will need to start the engine. After this, remove the breather hose. Just warm air should come out of it, or, in extreme cases, light smoke. If the smoke is gray and dense, and smells like exhaust, then the cause of poor compression is problems with the piston group. Possible burnout of the piston or;

- Next, regardless of what you see when removing the hose, you should unscrew the spark plug from the problem cylinder. It should be considered. If the piston is damaged, it will be in oil. A burnt-out valve is easily determined by the absolutely normal condition of the spark plug;

- Remove the cylinder head and replace the damaged part. Even if you are not going to change the entire set of valves, but want to get by with replacing only the damaged one. Be sure to lap the valves.

Conclusion

. Few drivers know how to correctly identify a burnt valve. Therefore, they spend time and money on completely different parts and components of the car, without solving the main problem. The symptoms and signs of a burnt valve are quite simple. Knowing them, even a novice auto mechanic will be able to make an accurate diagnosis in just 15 minutes.

The design of the gas distribution system of most internal combustion engines includes a valve system. It regulates the timely flow of air or combustible mixture into the combustion chamber and the release of exhaust gases. The valve itself constantly operates in aggressive conditions under the influence of high pressures and temperatures, which destroy the body of the part, leading to engine failure. There are certain reasons and conditions under which valve burnout occurs much faster than the design period of operation.

How often are adjustments made?

If we talk about mileage, then it is 20-30 thousand km. Adjustment of the thermal clearances of the valves should be carried out even if you do not experience a loss of power, increased fuel consumption and black smoke from the muffler (you should not wait for the first symptoms to appear). It is best to carry out the procedure in a car service center, but if you have the appropriate tools, equipment and experience, this can also be done in your garage.

Why is valve adjustment necessary? The design of a four-stroke internal combustion engine is, in principle, quite simple and understandable. The air-fuel mixture from P enters the. Then, the valves close and the process of compressing the mixture begins, which occurs due to the upward movement of the piston.

P Next, at a certain moment, approximately near the top dead center of the cylinder, the mixture is ignited, which is carried out. Obeying the laws of physics, the mixture expands under the influence of temperature and pushes the piston back down, converting thermal energy into mechanical energy. The last stroke of the piston is the release of exhaust gases into the exhaust system through the opened ones.

As you can see, everything is simple. P In this description, there was twice a mention of valves, inlet and outlet, which require periodic adjustment of the so-called thermal clearances. Let's see together what it is and why it is needed. P So, thermal clearance is a special gap left between the cam (or rocker arm) and the valve stem.

Its necessity is very simple - when the engine heats up, the metal, obeying the same physics, begins to expand, and the valve (more precisely, its stem) lengthens. The gap is designed to level out this expansion. Everything seems to be simple and clear again.

However, over time, approximately every 40,000 km, the valve clearances decrease and become (as a rule) larger than required. In this case, they need to be adjusted and returned to the original value, because the resulting excessive gap will lead to wear on the camshaft cam, since an impact load will appear on them. Let me explain. In a normal situation, when the thermal clearance is within normal limits, the rocker arm (or cam) is in constant contact with the valve stem. The stem, with a correctly adjusted gap, adheres to the rocker arm or cam when heated. However, if the gap is increased, there is a loss of contact when the rocker arm (cam) is removed and, conversely, a shock at the moment of contact.

This state of affairs will quickly break either the cam or the rocker arm, which will ultimately lead to expensive repairs (although, let's be realistic, few people actually make such repairs). Without it (repair), the engine will rumble when cold and run noisily when warm. We hope we were able to clearly convince you that the valves need to be adjusted. Now we will tell you why this operation should be trusted only to an understanding person. Often, people come to car repair shops with a complaint that they take care of the car, change everything on time, all operations are done strictly according to the regulations (or close to it), but the car just got mopey. This often happens after adjusting the valves, and it turns out that the adjustment can also cause harm, especially if you do not observe the dimensions of the thermal clearances and make them smaller than required! P What happens if the valves are pressed too tightly? Let's return to physics, according to which objects expand when heated.

Why do valves burn out?

Any rubbing part of a car wears out over time. As for the valves, it is the exhaust valves that burn out more often, since, unlike the intake valves, they are not cooled by the air flow, heat up to 650 o C and are more vulnerable to burnout. In them, the main heat removal occurs through the seats and guides, which means that good contact of the part with the seat is very important. The main reasons for valve burnout are the following:

- The appearance of carbon deposits on the valve and seat, creating additional heating.

- Worn valve seat or guide, which prevents complete heat dissipation.

- Violation of the valve seating height after lapping, due to which its rod sticks out higher and disrupts the geometry of the rocker arm, and when heated, the required clearance disappears.

- Underestimation of the permissible valve clearance and wear of the seat, as a result of which, after heating, the valve does not press well against the seat, allows gases to pass through, overheats and burns out.

- Engine overheating due to a breakdown of the cooling system.

- Increased fuel combustion temperature due to late or early ignition, or engine operation on a lean mixture.

- Difficult exhaust due to clogged catalytic converter or damaged exhaust manifold.

Causes

There are several reasons why valves can burn out:

- Manufacturing defects. The likelihood of deviations from the norm during the production of components is small, but still exists. Heterogeneity of the metal, defects in welding seams, microcracks are the first signs of defects.

- Critical temperatures. The operating temperature of the valves fluctuates around 650 °C. If the heat dissipation system is faulty, excessive overheating will cause the metal to quickly deteriorate.

- Poor quality gasoline. A lean fuel mixture leads to temperature spikes, which is even more damaging to the valves.

- Gas. Gas-powered engines are subject to greater loads than gasoline engines. Especially if the car is set to low gas supply. It is recommended to calibrate the valves every 10 - 15 thousand km.

Symptoms of a burnt valve

The main sign of a burnt-out valve is a distinct tripping of the engine in all operating modes. Power also drops noticeably and fuel consumption increases. Signs of failure are similar to other engine problems, and it is easy to confuse it with the following problems:

- Wear of piston rings and loss of compression in the cylinders.

- Breakage of high-voltage wires and spark plugs.

- Failure of injectors and malfunctions of the power system.

To accurately diagnose the malfunction, exclude all of the above options in the following order:

1. Checking the serviceability of the spark plugs is carried out with the engine running at idle speed by sequentially disconnecting the cap of each spark plug. When removing, carefully monitor the engine reaction and stability of its operation. If the engine starts to run worse, it means the valves in the cylinder are intact. If the nature of the operation has hardly changed, then most likely the problem cylinder has been detected.

2. On the faulty cylinder, replace the spark plug with a known working one, check the high-voltage wire and ignition coil. After starting the engine, it becomes clear whether there was a breakdown in the ignition system, or whether further diagnostics are required.

3. If, when replacing faulty parts of the ignition system, the engine continues to stall, the cause of the breakdown may be a burnt-out valve or a malfunction in the piston group in the form of sticking or wear of the rings. Both failures lead to low compression in the problem cylinder, but by measuring it it will not be possible to determine which of the two failures occurred. To do this, perform the following additional diagnostics:

- After measuring the compression, pour a few ml of engine oil into the problem cylinder through the spark plug hole and take another measurement. If the compression has increased, then the problem is with the rings, if not, then the valve has burned out;

- The spark plug on the problem cylinder is inspected. If the valve is burnt out, it will be completely dry and without any oil deposits. If the failure is related to the piston group, then the spark plug will be covered with oil, and when the engine is running, bluish smoke can be observed from the removed breather.

Difficulties in diagnosis

There is an opinion that if a valve burns out, symptoms and problems will be hidden in the ignition system. Very often, car mechanics, who still have little work experience, first of all begin diagnosing and repairing the ignition.

In the process of such repairs, the distributor cover is replaced, high-voltage wires and spark plugs are replaced. The ignition angle is also set - of course, there is no result and there will not be one. The engine has worked and will continue to work. The car mechanic will continue to look for the problem, not knowing the true cause of the problem. Even those mechanics who guessed that the problem lies in the engine see signs of burnt valves only after removing the cylinder head.

On the subject: What to spend money on and what not: 5 things

Replacing burnt out valves

The operation of replacing the valves of different engines is similar, and differs only in the size of the parts and their placement on the cylinder head. Before performing the operation, prepare lapping powder, new valve seals and a new head gasket. After dismantling the cylinder head, operations are performed in the following order:

1. Valve desiccation. To do this, the head is laid out on a flat surface and a rubber mat is placed under the valve. A tube with a diameter of 13 mm is placed on the valve so that the crackers are inside, and blows are applied with a hammer. The valve desiccates, and the crackers remain in the tube. The operation is also easily carried out using a special device that compresses the vein and allows you to pull out the crackers.

- The valve is pulled out, a new one is inserted, and the bushing guide is checked by shaking. If runout is up to 1 mm, the guide is not replaced.

3. If it is necessary to replace the guide, use a special mandrel. The old part is knocked out in the direction of the camshaft using a half-sledge hammer with a heavy blow so that the part does not crumble. Afterwards, a new bushing is driven into the head, having first put a retaining ring on it.

4. The new valve is secured with a retaining ring and the assembly is lubricated with oil.

5. Valve grinding. The seat is initially treated with a special cutter, after which lapping powder is applied to the edge of the valve, inserted into the head, the other end is clamped into the drill chuck, and by pulling it up and down, the valve is provided with a tight fit to the seat. It is advisable to carry out the operation for all valves.

6. Drying of the valve. To do this, press the spring firmly and insert crackers. The cylinder head is attached to the engine cylinder block.

The described method allows you to replace the burnt valves of all models of the VAZ: 2101, 2102, 2103, 2104, 2105, 2106, 2107, 2108, 2109, 21099, 2110, 2111, 2112, 2113, 2114, Niva, Lada Priora, viburnum, Grant, Grant, Grant. Vesta and most foreign cars.

Adjustment of valves

Valve adjustment is carried out on vehicles that require this type of maintenance, after replacing a part and at certain intervals during the vehicle's mileage. To do this, with the engine cooled down, the valve cover and the toothed belt protective cover must be removed, the spark plugs must be unscrewed and the oil must be removed from the tanks in the head. Before the procedure, the surface of the cams is inspected: they should not have holes, burrs or other damage. To control the size of the gap, feelers with a width of 10 mm are used.

The procedure for adjusting the valves is as follows:

1. In the cylinder on which the adjustment will be made, the first piston is installed at TDC by aligning the mark on the pulley and the cylinder block, at this moment all the valves on it are in a closed state. The adjustment procedure is determined by the manufacturer. To adjust the next cylinder, turn the crankshaft clockwise 180°, and the camshaft accordingly turns 90°.

2. Loosen the lock nut on the bolt or screw, insert the feeler gauge under the rocker (rocker arm), and adjust the height by placing a washer or rotating the adjusting bolt (depending on the design of the cylinder head). When the required clearance is established, the locknut is tightened.

3. After tightening, check the gap again. If it does not meet the norm, the procedure is repeated again. With excellent adjustment, the probe should enter with little effort, but not bend.

Thermal gap - what is it?

Ideally, the camshaft lobe and tappet should be pressed as close together as possible so that the surfaces are in perfect contact. BUT we all know that the engine consists of metal (aluminum and cast iron are not important), and valves, tappets and camshafts are also made of other metals. When heated, metals tend to expand (elongate).

And the gap, which was ideal on a cold engine, becomes incorrect on a hot one! In simple words, the valves become pinched (this is bad, we’ll talk about it below).

It follows from this that on a cold engine, it is necessary to leave special thermal gaps with compensation for expansion when hot. These values are small and are measured in microns with special probes. Moreover, at the inlet and outlet these values differ

If the thermal gap between the camshaft cam and the valve tappet decreases or increases, then this is VERY bad for the performance of the engine and the timing mechanism itself as a whole . Now each manufacturer has a special regulation for adjusting this “thermal gap” (this is called “valve adjustment”) - it usually ranges from 60 to 100,000 km , it all depends on the materials used in the design. As I wrote above, adjustment is carried out by selecting either “solid” pushers or replacing “washers” in the upper part.