Since the car itself is in St. Petersburg, and I live in Anapa right now, but at work I was given a 3110 with a face from 105, let me ask myself here the engine 406, the clutch was at the very bottom when you touch it, etc., but today I stopped at a gas station, then drove up pump up the tires, and decided to turn around to pump up the other side, but the gear doesn’t engage, I squeeze the clutch, oops, it doesn’t engage, they spat, we drove on, to a friend, we press the gear and down the hill, accelerating the car, it turns into a gear, then into a higher gear, so and drove in 2nd gear all the way home and bled the clutch, it didn’t help, then I noticed that the fork was resting on the clutch housing, what could it be?

FakeHeader

Comments 7

Then I can't know. You can, of course, assume that the fork jumped off the soldier or from the release lever (only from the lift in the crankcase window with a flashlight or look at the car by driving the wheel onto something)

yes, that’s what I did, I threw the disc under the wheel, and lay down in the hole, visually the fork is straight, everything is in place, but as mentioned above, perhaps the rod was pressed through

Try adjusting the pedal at the junction with the cylinder head (unscrew the tip on the cylinder head several turns).

I turned it, it doesn’t help, the point is not that the pedal doesn’t have enough travel. but the fact that the fork rests on the slot of the bell

This means that the fork is bent)))

I also have such thoughts, but it’s not visually clear that it’s bent

Well, visually you need to not just look at it, but compare it with the new one, because... It's not always noticeable. On my gazelle it constantly bends (despite the fact that it is additionally boiled), but it is only noticeable when you compare it with a new fork. In general, I once changed the clutch, and decided to change the fork at the same time. And when the car warmed up, the pedal went to the floor and did not return, and when I tried to pull it back with my hands, it would no longer be pressed, i.e. stood up like a stake. After the car cooled down, the pedal began to move, but the clutch engaged only 3 seconds after the clutch pedal was completely released. I thought that the basket was defective, and after inspection, I accidentally stuck the old plug back in, and everything was fine))). New fork compared to old 1 in 1)))

AutoNews / Reviews / Tests

Replacing the Gazelle 406 Clutch Fork

Adjusting and replacing the clutch on a Gazelle

Replacing the working or master cylinder of the clutch on a Gazelle, as well as other parts, can prevent car failure. It is important to diagnose and repair the vehicle in a timely manner, and replace the clutch kit and other components as needed. In the future, this will help avoid breakdowns on the highway and accidents.

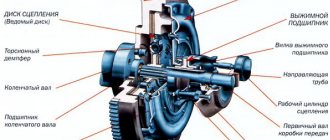

Clutch diagram for Gazelle

Causes of clutch failure and solutions

If the engine roars loudly, the car accelerates slowly, and there is a distinct burnt smell in the cabin, then this clearly indicates that the clutch disc has burned out.

So, let's look at the reasons why clutch discs may burn.

Bravado and idiocy are different concepts, but, unfortunately, they often go hand in hand. For example, in winter a motorist “sat” in a snowdrift. His actions? Well, that's right: gas to the floor (so that you can reach the ground)! But it is in this way that he himself burns the clutch discs. But going out and putting branches under the wheels or the same “shoe” or jack is weak?!

In the summer?! Well, where did this habit of accelerating while slipping come from: so that the tires squeal and smoke pours out from under them? Result: clutch discs burn. How they burn: they turn blue. And the blue color is an indicator that the metal is overheated and has become very fragile and thin. What kind of normal clutch can we talk about?

Diagnosis of clutch problems

You got into the car and pressed the clutch pedal. Do you hear creaking and squealing noises? Then you have problems with the release bearing: it is worn out and jammed. And this is very bad, since it is this part that allows you to connect the gearbox to the engine and change gears without jerking. The solution is to immediately replace the part!

When you get to the service center, you should not blindly trust the specialists with your car. You must understand that the best rule in this case is “trust but verify.” Stay nearby and follow the car diagnostic process. For example, if your release bearing is broken, then it is not at all necessary to change the clutch disc and basket, but the master can offer you this, because this is his income.

If the clutch is hydraulic, then the clutch pedal may simply fall through and not return to its original position. This indicates that one of the cylinders has broken: the worker or the main one.

If air gets into the hydraulic system of the clutch control mechanism, it is necessary to bleed the clutch.

If the clutch drive is mechanical, then thin steel cables are involved in the process. They can tear, stretch or come off. Naturally, the car won’t move: the pedal doesn’t work.

Getting to the clutch on a car with rear-wheel drive is very simple: in this case the box cannot be removed, you just need to carefully push it aside. If it is front-wheel drive, the box will have to be removed.

We remove the clutch disc and look at its condition. As a rule, a burnt disc becomes thin and blue: the consequences of overheating. Such a disk should be replaced along with the basket, which burns at the point of contact with the disk.

If everything is in order with the disk, then we look at the bearing. Rock it by hand: if it dangles (there is play), then the bearing should be replaced.

And one last thing. When the service technician installs the clutch in place, we strongly recommend that you ensure that he centers the disc! This process is carried out using a special mandrel. If this is not done, then when assembling the box the input shaft will not fall into place. We do not recommend inserting the shaft with force: it may break, and this already threatens to repair the gearbox.

And most importantly: after the master removes all the “dead” parts, ask him to give them to you. This way you will have at least some guarantee that the problematic parts are actually replaced with new ones and that “new” spare parts will not be installed from your hardware for the next client’s car.

Kolodiychuk Andrey

, especially for

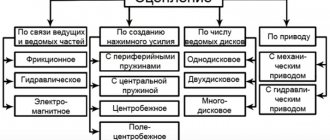

Operating principle of the clutch system

To transmit torque to the driving wheels of the vehicle from the engine crankshaft, a box is provided, because smooth transmission of torque from the motor to the wheels is unprofitable. The car will not be able to move without a clutch, and the operation of the power unit itself will be ineffective.

For comfortable operation of the power plant, the torque removed from the crankshaft must be changed in advance in the gearbox (gearbox). After which it moves to the driven axle. Since changing gears forces the gearbox gears to spin, which hit each other with force, it can be difficult to change gears. If the box is always connected to the unit, in order to completely stop the vehicle, it will be necessary to stop the motor.

How to make a quality replacement

Carrying out minor repairs, replacing the clutch fork, including adjusting its pedal, will not require much time. If there are high-quality parts, for example, made by Sachs or Kraft, the replacement will only take about 2 hours.

The Gazelle clutch requires proper handling and timely replacement as a result of frequent repairs and adjustments. Replacing the entire assembly is not necessary in every case. The stages of replacement depend on the brand of Gazelle car, determined by the engine, for example, Cummins ZMZ 406 and 405, etc.

The clutch kit must include a fork, a disc, a hydraulic hose, a hydraulic clutch, a clutch basket, a release bearing, the price of which from the manufacturer is lower than the cost of parts offered by chain stores. After diagnostics, it may be necessary to replace only the clutch slave cylinder, which operates under fairly high loads. In some cases, it is necessary to solve the problem with changing the gearbox, discovered as a result of system diagnostics.

Sometimes it may be necessary to check the entire pipeline and also bleed the system. The cause of the violation may be damage to the reservoir included in the Gazelle clutch kit.

Causes of clutch failure

Replacing the clutch may be necessary as a result of intensive use of the Gazelle car and if the following errors occur:

The process of replacing the clutch on a Gazelle

- Low quality parts were used during assembly.

- The clutch pedal was kept depressed while driving, which is strictly prohibited by the manufacturers.

- There were jerks from a standstill at high speeds.

To increase the service life of the Gazelle clutch, installation of parts manufactured by the manufacturing company Sachs will be reliable. They are recommended by the manufacturer because they are reliable and have been tested for installation compatibility with the transmission and engine. Under the same conditions clutch , unlike parts from other manufacturers, will last longer. A common analogue of the Gazelle Business clutch, produced by Kraft, is not only of good quality, but also has a fairly low defect rate. The most common reasons why Gazelle owners contact service departments are malfunctions related to the clutch release drive.

content .. 127 128 129 130 ..Gazelle until 2009. The clutch does not disengage (drives)

The clutch does not disengage completely (drives): the main reasons

| Replace the driven disk | |

| Wear of the diaphragm spring blades at the point of contact with the release bearing | Replace drive disc assembly |

| Jamming of the driven disk hub on the splines of the input shaft of the gearbox | Inspect the splines; if the hub is significantly damaged, replace the driven disk. Before assembly, apply CV joint-4 lubricant to the gearbox shaft splines. |

| The driven disk is “stuck” to the flywheel or drive disk (after a long stay) | Place wheel chocks, engage first gear and parking brake. Press the brake and clutch pedals simultaneously and turn the engine crankshaft using the starter. |

| Incorrect clutch drive adjustment (full pedal travel is too small) | Adjust the drive |

| Loosening of rivets or breakage of friction linings, warping of the driven disk (axial runout in the area of the linings is more than 0.5 mm) | Replace the driven disk |

| Severe and uneven wear, scoring on the working surfaces of the flywheel or pressure plate | Replace flywheel. If the pressure plate surface is damaged, replace the clutch cover |

| Distortion or warping of the pressure plate | Replace clutch cover |

| Jamming of the driven disk hub on the splines of the input shaft of the gearbox | Clean the splines from dirt, remove minor damage with a file. If the splines are significantly worn or damaged, replace the transmission disc and/or input shaft <STO> |

| Loosening of the rivets of the spring plates of the clutch housing, breakage of the plates | Replace clutch cover |

| Clutch release bearing jammed | Replace bearing |

Clutch leads

The term clutch “floats” means that the clutch does not disengage completely when the clutch pedal is depressed. When the clutch pedal is released, it is constantly on. After pressing the pedal, the force is transmitted through the cable and fork to the release bearing, which presses on the petals of the “basket” pressure spring. The spring acts on the drive disk, which stops pressing the driven disk against the working surface of the flywheel. The transmission of torque from the engine to the gearbox is interrupted. You can change gears.

If for some reason the driven disk is not sufficiently moved away from the flywheel, shifting forward gears will be difficult, and the rear gear may engage with a crunch and crackle.

Reasons that the clutch is leading

Clutch drive not adjusted

Full pedal travel is insufficient. The clutch pedal is located below the brake pedal.

adjusting the clutch drive by rotating the adjusting nut

Drive cable jamming in sheath

Over time, the drive cable may wear out, the wires in it become frayed, which makes it very difficult to move in the sheath. As a result, when you press the pedal, the clutch does not disengage completely (drives).

The driven disk is faulty

The driven clutch disc may be warped (its end runout is more than 0.5 mm). The driven disc hub may bind to the input shaft splines if they are heavily dirty or worn. In any case, the driven disk will not move away from the flywheel to the required clearance.

The flywheel or pressure (drive) disk of the basket is faulty

Severe scuffing on the flywheel or drive plate working surfaces may prevent the driven disc from rotating freely.

The clutch pressure damper spring is faulty

Severe wear of the ends of the spring petals at the point of contact with the release bearing.

Notes and additions

— In some cases, difficult gear shifting can be caused by reasons not related to the clutch. For example, breakage, deformation, incorrect adjustment of drive elements of the gear shift mechanism.

content .. 127 128 129 130 ..

Operating principle of the clutch system

To transmit torque to the driving wheels of the vehicle from the engine crankshaft, a transmission is provided, since direct transmission of torque from the engine to the wheels is unprofitable. The car will not be able to move without a clutch, and the operation of the power unit itself will be ineffective.

For convenient operation of the power plant, the torque removed from the crankshaft must first change in the gearbox (gearbox). After this, it switches to the drive axle. Since changing gears causes the gearbox gears to rotate, which hit each other with force, it can be difficult to change gears. If the box is constantly connected to the power unit, in order to completely stop the vehicle, you will also need to stop the engine.

Clutch operation in a Gazelle car

The principle of its operation is the same for any brand of car. It eliminates the possibility of rapid wear of components and parts that connect the power plant and transmission.

The clutch pressure plate, attached to the housing, presses the driven disc against the flywheel. The disc hub attached to the input shaft must be able to move freely along it. The hub body is equipped with damper springs, which act as vibration dampers and ensure smooth running.

To create the required pressing force, a spring with petals is provided, which are exposed to the release bearing. It is the connecting link between the drive and the clutch, onto which the fork with the lever is attached. Another lever or cable is attached to its end, leading to the clutch pedal.

Why can't you keep your foot on the clutch pedal all the time?

Often, novice drivers try to simplify communication with a manual transmission. They don’t press the pedal all the way, and on a long journey they don’t bother moving the shoe to a special platform. What could this lead to?

The manual transmission, for all its reliability and high service life, has a number of weak points. First of all, it's the clutch. It consists of disks, springs, release bearings, levers and many other mechanisms. In the released position of the pedal, the clutch discs are in working condition and are tightly compressed by the springs. The technical unit transmits torque from the engine to the transmission.

To change gearbox stages, you have to briefly depress the pedal and open the discs. Then the input shaft of the box is disconnected from the engine crankshaft, and at this moment the desired gear can be selected. After this, the clutch pedal returns to its place, and the foot must be removed to a special resting area.

However, some drivers leave their foot on the pedal and drive like this all the time. They justify their actions by the fact that in case of a dangerous situation they will be able to quickly squeeze the clutch for emergency braking. Others are simply afraid to miss and mix up the pedals. However, no emergency occurs for months, and the foot still remains on the pedal.

This skill is partly developed in driving schools. Instructors even teach you to keep the shoe on the clutch to regulate speed at extremely low engine speeds. For example, you need to drive around the site at a speed of 3 km/h, and when the pedal is released, the car immediately accelerates to 10 km/h. Instructors advise periodically opening the clutch discs all the way and returning them back to prevent the car from accelerating. But beginners, instead of unlocking, only press the pedal a little, causing the discs to unclench just a little and rub against each other. The torque from the engine is transmitted by half, and the car actually drives slower. The rest of the energy goes into friction of the discs and is converted into heat.

The unit gets very hot and eventually fails. For training machines this is not a problem. Instructors don’t fix them; they just need to quickly train people to pass the training ground, send them to exams and accept a new batch of students. Worn-out cars will be sent for sale after the warranty expires.

However, if graduate drivers also drive their own cars every day, then problems with equipment cannot be avoided. The fact is that, unlike cheap student vehicles, modern cars are already equipped with a hydraulic clutch release drive. The foot left on the pedal transmits force to the hydraulics, and it multiplies it many times and puts pressure on the fork, levers and release bearing. The discs lag a little behind each other and begin to slip.

Many months of driving with a boot on the clutch pedal lead to severe wear on the discs. Already after 10-15 thousand kilometers, problems with switching begin. There may be an unpleasant smell coming from under the hood. After this, it is necessary to remove the box and carry out expensive repairs. Otherwise the car will simply stop.

In general, in pursuit of the convenience of positioning the leg, you can inadvertently harm the “iron horse”. Therefore, the left foot should always be on the platform to the side of the pedal. The designers specifically designed it for relaxation.

How to make a quality replacement

Carrying out minor repairs, replacing the clutch fork, including adjusting its pedal, will not require much time. If there are high-quality parts, for example, made by Sachs or Kraft, the replacement will only take about 2 hours.

The Gazelle clutch requires proper handling and timely replacement as a result of frequent repairs and adjustments. Replacing the entire assembly is not necessary in every case. The stages of replacement depend on the brand of Gazelle car, determined by the engine, for example, Cummins ZMZ 406 and 405, etc.

The clutch kit must include a fork, a disc, a hydraulic hose, a hydraulic clutch, a clutch basket, a release bearing, the price of which from the manufacturer is lower than the cost of parts offered by chain stores. After diagnostics, it may be necessary to replace only the clutch slave cylinder, which operates under fairly high loads. In some cases, it is necessary to solve the problem with changing the gearbox, discovered as a result of system diagnostics.

Sometimes it may be necessary to check the entire pipeline and also bleed the system. The cause of the violation may be damage to the reservoir included in the Gazelle clutch kit.

Causes of clutch failure

Replacing the clutch may be necessary as a result of intensive use of the Gazelle car and if the following errors occur:

The process of replacing the clutch on a Gazelle

- Low quality parts were used during assembly.

- The clutch pedal was kept depressed while driving, which is strictly prohibited by the manufacturers.

- There were “jerks” from a standstill at high speeds.

To increase the service life of the Gazelle clutch, installation of parts manufactured by the Sachs manufacturing company will be reliable. They are recommended by the manufacturer because they are reliable and have been tested for installation compatibility with the transmission and engine. Under the same conditions, the Sachs clutch, unlike parts from other manufacturers, will last longer. A common analogue of the Gazelle Business clutch, produced by Kraft, is not only of good quality, but also has a fairly low defect rate. The most common reasons why Gazelle owners contact service departments are malfunctions related to the clutch release drive.

Among the main problems are:

- leak of the Gazelle clutch master cylinder (MCC);

- removal of brake fluid from the hydraulic fluid reservoir;

- Clutch slave cylinder (CLC) leak;

- bypass of the cuff of the central nervous system;

- bent or fallen out working cylinder rod, etc.

Careful operation of the car does not imply any “jerks”, but only the presence of conditions that allow you to move off smoothly and change gears while the car is moving. Most often, clutch replacement is required for trucks. A Gazelle car intended for business requires increased attention to this unit, the elimination of breakdowns in which is often not possible. Since replacing the device does not require removing the motor, you can repair the clutch or install new parts yourself.

Diagnostic principle and clutch replacement rules

Incorrect operation of the clutch system is determined by the following main points:

- noise is heard in the gearbox when the car is moving;

- the transmission turns off spontaneously;

- changing gears causes various extraneous noises;

- Changing gears is difficult.

Why did the pedal fail?

This is what a failed accelerator looks like

. So, there may be several reasons:

- First of all, these are problems with hydraulics. You should check the brake fluid level in the clutch master cylinder expansion tank. If there is little liquid, then it must be added to the required level. If you did this and the pedal returned to its place, you can consider yourself lucky. In this case, you need to get to the nearest service station or check all the brake system pipes yourself; it is possible that the brake fluid is simply leaking. In this case, the problem may also be a broken pipe, which will subsequently have to be replaced.

- When the cable breaks. The clutch cable can break in the middle or at one of the ends, sometimes the eye on the pedal itself breaks. The problem can only be solved by replacing the failed component with a new one.

- Problems with the operation of the clutch release fork. This fork is located directly at the gearbox, its service life is on average up to 70 thousand km. If this component does break, we also recommend immediately replacing the clutch disc.

- In case of failure of the main or working cylinder of the system. Often a component simply fails; the fault can be resolved by replacing the component.

- If the return spring breaks. It could jump off the installation site or burst. If it breaks down, the vehicle will have to be towed to the nearest service station.

- If air gets into the hydraulic drive. The malfunction can be solved by bleeding the clutch; more detailed information about this process can be found on our website.

- If the accelerator still fails, but you can squeeze it out by pressing it sharply, then the malfunction, most likely, lies in the incorrect functioning of the cylinder. In particular, we can talk about defects in the operation of the cuff or about its failure. Such a breakdown can only be solved by replacing the main cylinder.

One way or another, you are unlikely to be able to solve this problem right on the road. The only exceptions are breakdowns that can be solved by bleeding the system and removing air from it. You will have to seek help from specialists or do the repairs yourself.