Home » Connection, installation, configuration » What is a duct air conditioner: principle of operation, selection and installation of the device

Connection, installation, configuration

Author Elena Davydova Reading time: 16 min. Views 1.3k. Published 10/22/2017

When choosing an air conditioner for a home or other buildings, you need to take into account, first of all, their area and configuration. Thanks to this, you can effectively set up the operation of your equipment, completely eliminating possible overloads and unnecessary electricity costs. A ducted split system is an ideal option for a private house, apartment and other premises that have high ceilings and large areas.

- Purpose of a duct air conditioner and features of its design

Video: ducted air conditioner with fresh air supply

- Calculation of air ducts for a duct air conditioner

Video: laying air ducts for a ducted air conditioner

- Planning a ducted air conditioning system

- Video: how to install a duct air conditioner

- Video: Daikin duct air conditioners in an apartment

Calculation of air ducts for a duct air conditioner

To correctly calculate air ducts, you need to know the maximum air flow rate in the system and the volume of air that passes per unit of time. The higher the air speed, the smaller the duct sizes, but the higher the noise level and energy costs. Air speed for private houses usually does not exceed 4 m/s, since at high speeds its movement becomes very noticeable. In industrial buildings, air flow speed can reach 8 m/s.

In addition, it must be taken into account that it is not always possible to use low-speed air ducts with a large cross-section, since they will be difficult to install in the space behind the ceiling. Rectangular ducts help reduce the height of this space, but it is faster and more convenient to install a system of flexible or round ducts.

The use of rectangular air ducts allows you to reduce the size of the installation gap under the ceiling, but round ducts are easier and more convenient to install

The area of the air channel can be calculated using the formula Sc=L*2.778/V, where:

- V is the speed of air flow;

- L—air flow;

- Sc is the required area.

Video: laying air ducts for a ducted air conditioner

Planning a ducted air conditioning system

The importance of planning a ducted indoor air conditioning system cannot be underestimated. Any building is unique in its own way, therefore, in each individual case, its own specific air conditioning system is selected.

Installation of the duct system is carried out in premises with large areas (trading floors, offices, production) or in individual buildings. Combining several systems into one helps to benefit from ducted equipment in relatively small spaces.

Duct air conditioners are usually installed in large office, retail or industrial premises

When planning a duct system, you must consider several characteristics:

- air conditioner power consumption;

- heating power;

- cooling power;

- air exchange or productivity. Expressed as the air exchange rate in 60 minutes for a certain volume of the room;

- air pressure. This indicator is critical for large premises that require air duct systems of considerable length. An air conditioner, which gives excellent performance due to the air flow rate for short channels, will not draw a lot of air on a long channel with little pressure. And this will negatively affect the efficiency of the system;

- weight and dimensional parameters.

System planning should be carried out by a professional who will not only correctly perform all the necessary calculations, but will also be able to select the desired type of climate system device.

Product classification

The installation of a ducted air conditioner at home is largely determined by the characteristics of the home. First you need to choose a suitable model. Modern systems can be divided into several types.

In this case, various indicators matter. The pressure of the fan located in the indoor unit matters. This parameter is measured in Pascals. This indicator represents pressure. There are low-pressure, medium-pressure and high-pressure air conditioners. Strong pressure is required to force air through the ducts. There are products that are classified according to the type of electrical circuit.

In this regard, start-stop type air conditioners . Here the compressor operates at the same speed. For the same reason, the heat pump power does not change. To maintain the temperature at a certain level, you need to turn off the cooler from time to time.

Another option is an inverter air conditioner . It's more modern. Here in the electrical circuit there is a component called an inverter. It makes it possible to obtain alternating current of any frequency. Accordingly, the speed of the compressor can be better controlled. Pump power can also be better monitored. The inverter model determines the best cooling power and operates in this mode on an ongoing basis. It doesn't turn off. At the same time, the described equipment costs 2 times more than standard equipment that has the same power indicators.

Sellers often attribute non-existent benefits to inverter air conditioners to improve sales. For example, some of them claim that such equipment supposedly saves electricity. But there are no statistics that could confirm this. In certain cases, the inverter model can even result in higher costs. It is also not true that a specific operating mode contributes to a longer service life. Experienced craftsmen will refute this statement.

Suffice it to recall the compressors of old refrigerators, which worked in start-stop mode for 10 years, but were not subject to breakdown. The replacement of such a device could only be due to the fact that it was obsolete. But such a compressor itself is a very durable unit.

There is an opinion that an inverter air conditioner makes less noise. But the source of the sound is the fan in the indoor unit, which drives the air. The inverter does not play a special role here. The fact is that the compressor is specially placed in the outdoor unit so that it cannot be heard in the room.

We recommend that you read: Operating principle and installation of household mobile air conditioners

The tangible advantage of such models is that they keep the temperature stable. Fluctuations can be no more than 3 degrees. In addition, they are able to supply less cold air. This circumstance reduces the likelihood of catching a cold, which is especially important during sleep, when the human body is most vulnerable.

Selection of duct air conditioner

Nowadays there are duct air conditioners from dozens of manufacturers from different countries on the market, so in order to purchase quality products you need to understand this issue very carefully.

- Budget class air conditioners. Reliable, high-quality and at the same time inexpensive devices include products from Korea, Italy and Japan. All production of air conditioners from Hyundai, Dantex and Shivaki is controlled by their representatives. When manufacturing their products, these companies use only high quality components. Each presented company has its own extensive line of models, and the best devices are not inferior to the equipment of more expensive class=”aligncenter” width=”652″ height=”278″[/img] Channel air conditioners from the Korean company Hyundai are of high quality at an affordable price

- Mid-level equipment. Popular Japanese brands such as Panasonic and Toshiba belong to the middle class. These manufacturers offer consumers the optimal combination of quality and price. Even the most inexpensive models of duct air conditioners have the highest characteristics and have been in use for many years.

Panasonic offers the highest quality equipment at an average price

- Premium technology. This category of air conditioners is represented by Daikin and Mitsubishi, which are market leaders. Such devices are reliable and of very high quality, and each unit of production is checked in all respects and undergoes control before sale, which allows companies to guarantee the excellent quality of their products.

In the premium segment there are world-famous manufacturers who guarantee the quality of each unit of their products.

The main parameters by which it is necessary to select a ducted air conditioner are the pressure created and the cold output.

- Static pressure is determined by the performance of the device’s fans, which must provide the required amount of air into the room for a certain time.

- The cooling capacity of equipment is the maximum amount of cold air produced by equipment over a certain period of time. This characteristic is indicated in the data sheet by the manufacturer.

Video: Daikin duct air conditioners in an apartment

Types, structure and principle of operation of the compressor

The compressor is a displacement type supercharger. It starts working after turning on the air conditioning button in the car. The device has a permanent belt connection to the motor (drive) through an electromagnetic clutch, which allows the unit to be started when necessary.

Air conditioning compressor

The blower sucks in cooled gaseous refrigerant from a low pressure area. Further, due to compression, the pressure and temperature of the refrigerant increases. These are the main conditions for its expansion and further cooling in the expansion valve and evaporator. To increase the service life of the compressor components, special oil is used. Some of it remains in the supercharger, the other part spreads throughout the system. A safety valve is located on the compressor, which protects the installation from excess pressure above normal.

There are the following types of compressors in air conditioning systems:

- axial piston;

- axial piston with rotating inclined disk;

- bladed (rotary);

- spiral.

The most widely used are axial piston and axial piston superchargers with an inclined rotating disk. This is the simplest and most reliable version of the device.

Axial piston blower

The compressor drive shaft drives the inclined disk, which, in turn, forms the reciprocating movement of the pistons in the cylinders. The pistons move parallel to the shaft. The number of pistons may vary depending on the model and design. There can be from 3 to 10. Thus, the work cycle is formed. The valves open and close. Refrigerant is sucked in and discharged.

Axial piston compressor

The power of the air conditioning system depends on the maximum compressor speed. Often performance depends on engine speed. The supercharger speed range is from 0 to 6,000 rpm.

To remove the dependence of the compressor operation on the engine speed, compressors with variable displacement are used. This is achieved by using a rotating inclined disk. The angle of inclination of the disk changes with the help of springs, which adjusts the performance of the entire air conditioning system. In compressors with a permanent axial disc, adjustment occurs as a result of turning off and turning on the electromagnetic clutch.

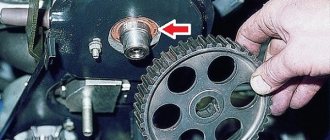

Drive and electromagnetic clutch

The electromagnetic clutch provides connection between the running engine and the compressor when the air conditioner is turned on. The coupling consists of the following components:

- belt pulley on a bearing;

- electromagnetic coil;

- spring-loaded disc with hub.

Electromagnetic clutch device

The motor drives the pulley through a belt connection. The spring-loaded disk is connected to the drive shaft, and the electromagnetic coil is connected to the supercharger housing. There is a small gap between the disc and the pulley. When the air conditioner turns on, the electromagnetic coil creates a magnetic field. The spring-loaded disk and the rotating pulley are connected. The compressor starts its work. When the air conditioner turns off, springs move the disk away from the pulley.

Maintenance of ducted air conditioners

Duct equipment is an air cleaning and cooling device that can absorb allergens, dust, and dirt. But in order for the equipment to work properly and provide good air purification, it is necessary to carry out its timely maintenance, which includes the following work:

- cleaning air conditioner elements;

- antibacterial treatment using high-quality chemicals;

- disinfection of equipment carried out with steam under high pressure;

- checking the functionality of all equipment parts (electrics, freon line, as well as the drainage system and units);

- quality control of thermal insulation.

Duct air conditioners are cleaned using special products that remove dust, odors and bacteria.

If the device is installed in a hidden manner, then maintenance also includes disassembling the cells and then reassembling them. In addition, the refrigerant level is measured and, if necessary, freon is charged.

At the final stage, the walls are treated from various contaminants with a special protective film.

Replacement or repair

Replace compressor clutch

air conditioner or repair?

Sometimes repairing some individual parts of this part is simply impractical. Some car enthusiasts have to search for the same bearing on the Internet. And the cost of the elements sometimes equals the cost of completely replacing the coupling, which is simply not profitable. In addition, this activity requires considerable patience and time. And it’s not a fact that the part won’t fail again soon.

That is why most often car enthusiasts prefer a complete replacement of the clutch over repair.

To avoid unpleasant consequences after intervention in the air conditioning system, experts recommend that people with insufficient experience entrust diagnostics, repairs, replacement of the clutch or any of its other elements to professionals in their field.

- saving time (work is completed within the specified time frame);

- saving money (you won’t have to overpay for something that wasn’t done to you);

- saving nerves (all work is guaranteed).