Electrolyte contamination

This problem can occur if the product is not properly cared for, when dirt gets inside the cans when electrolyte is not carefully added. The second reason is poor-quality battery repair, as a result of which the jumpers are soldered incorrectly. How to understand that the battery is faulty? This can be seen by the following signs:

- strong release of gases (especially during charging), caused by the appearance of copper in the solution;

- the appearance of light sediment at the bottom of the cans due to chlorine getting inside the battery;

- coloring of the electrolyte dark red, which indicates the appearance of manganese in the solution;

- The car battery does not hold a charge.

To solve the problem, drain the contaminated compound and fill the battery with distilled water. Then put the battery on charge, setting a small current. After an hour, remove the water, fill in the electrolyte of the required density and charge the battery with standard current.

Malfunctions of lead-acid batteries and ways to eliminate them

The main reason for any kind of battery malfunction is violation of operating standards.

Long-term charging, storage at high temperatures, deep discharges and other violations can cause breakdowns: The main malfunctions of lead batteries are:

1. Increased self-discharge.

The cause is current leakage. To eliminate the malfunction, you need to clean the surface and then neutralize it with an alkaline 10% solution containing soda ash or ammonia. When performing this procedure, you must ensure that the alkali solution does not get inside the battery and contaminate the electrolyte. Then the vessel must be wiped dry.

2. General contamination of the electrolyte.

If various types of impurities are detected in the electrolyte, it must be replaced in any case. First, the battery is discharged, the electrolyte is poured out, and then filled with distilled water. All this is charged for 1 hour, using a low current. After this, you need to drain the water and fill it with high-quality electrolyte. After completing these steps, the battery is charged with a standard voltage current.

3. Short circuit occurring inside the battery

Reduced density levels, reduced capacitance and reduced voltage are signs of a short.

To eliminate this breakdown, you first need to discharge the battery to the final voltage, only then can it be disassembled. Having disassembled the element, they replace the damaged separators, cut off the growths on the plates with a knife, remove the sludge and clean the vessels. After eliminating the short circuit, the battery is collected and charged.

4. Destruction of plates

A battery that is damaged due to the destruction of the plates is not suitable for use and must be replaced.

5. The most common malfunction is plate sulfation, which occurs as a result of improper use of the battery.

To eliminate the “white coating,” the battery is cyclically discharged and charged. During the charging process, carefully monitor the density and level of the electrolyte itself.

It should be noted that only the initial stage can be repaired due to sulfation. If the case is swollen, repair will not help. This battery only needs to be replaced.

6. Electrode polarity reversal.

An error identified in a timely manner can be easily corrected. It is necessary to switch the battery to the correct charging mode.

7. Cracks in the monoblock.

The monoblock to be repaired is washed well under running water and dried at room temperature for 3-4 hours.

Having disassembled the necessary element, use sandpaper to clean the crack until a rough surface is obtained. Then the cleaned areas must be degreased with a cloth, which is moistened in an acetone solution, and dried. It must be taken into account that the repaired monoblock must be tested for leaks.

Careful adherence to battery operating standards and regular maintenance of battery components will help eliminate the possibility of various malfunctions, thereby increasing the service life of the lead battery.

Malfunctions, their causes and solutions are given below. Battery malfunctions that occur during operation include oxidation of leads and wire tips, leakage, accelerated self-discharge, sulfitation, short circuit and premature destruction of electrodes.

Sulfitation—the formation of large, poorly soluble crystals of lead sulfate on the surface of the electrodes—occurs with increased electrolyte density, long-term storage of batteries without recharging, systematic undercharging, and contact of the electrodes with air due to a reduced electrolyte level. Batteries with sulfated electrodes quickly lose capacity when discharged.

A change in the volume of the electrodes during charge and discharge leads to the separation of the active mass from the gratings and its settling at the bottom of the monoblock. Deformation and destruction of the electrodes occur more intensely during short circuits and prolonged activation of the starter. Positive electrodes are oxidized by oxygen and are quickly destroyed when the battery is overcharged.

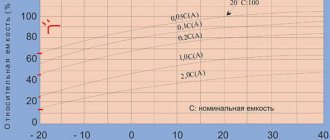

Due to the natural wear of the electrodes, corrosion of the grids and loss of the active mass of the positive electrodes, and compaction of the active mass of the negative electrodes, a gradual decrease in the capacity of the battery occurs. The rechargeable battery is removed from service when the capacity decreases to 40% of the nominal or the duration of the starter discharge decreases at temperature

(25 ± 2) °C up to 1.5 min.

The minimum service life of batteries of a conventional design and with a common cover in operation should be 1 year when the vehicle operates within this period of no more than 150 thousand km or 2 years when the vehicle operates within this period not more than 90 thousand km.

| Cause of malfunction | Remedy |

| The battery does not provide sufficient rotation speed of the crankshaft cranked by the electric starter | |

| Increased voltage drop in the starter power circuit Battery discharge below the permissible level Failure of one or more batteries Accelerated self-discharge of the battery due to electrolyte getting on the surface of the battery | Clean the battery terminals and wire tips, tighten the fastening of the wire tips on the battery terminals and lubricate them with technical petroleum jelly. Charge the battery, if necessary, check the serviceability of the generator set. Hand over the battery for repair. Wipe the battery with a dry cloth, and then with a cloth moistened with a 10% solution of ammonia or calcined alcohol. soda Discharge the battery with a 10-hour current until the voltage of one of the batteries is 1.1-1.2 V. Pour out the electrolyte, rinse the battery, pour fresh electrolyte into it and charge it. |

| Rapid decrease in electrolyte level | |

| Damage to the monoblock battery. Increasing charging voltage | Have the battery repaired. Check the voltage regulator and adjust if necessary. |

| A discharged battery does not charge well (the voltage and temperature of the electrolyte quickly increases, and abundant gas evolution begins) | |

| Electrolyte sulfation | Restore a battery with sulfated electrodes using a charge-discharge cycle at a current strength of less than 0.05C20 (A) in the case of an initial density of 1.12-1.14 g/cm3. If there is significant sulfation of the electrodes, take the battery in for repair. |

| Electrolyte splashing out of the vents during charging | |

| Increase in electrolyte level Increase in charging current Short circuit of plates in battery | Remove excess electrolyte with a rubber bulb Check the voltage regulator, adjust if necessary Send the battery for repair |

The minimum service life of maintenance-free batteries in operation should be 3 years with a vehicle operating time of no more than 100 thousand km.

The minimum shelf life of a battery not filled with electrolyte should be 3 years. Dry charging must be maintained for at least 1 year. For maintenance-free batteries filled with electrolyte, a shelf life of 2 years is established, subject to an intermediate charge within the minimum service life.

BATTERY CHARGE:

1. Connect the positive terminal of the battery to the positive terminal of the power source, and the negative terminal to the negative terminal.

2. Charge the batteries if the electrolyte temperature in them is not higher than 30°C in cold and temperate zones and not higher than 35°C in hot and warm humid zones.

3. The charge current must correspond to the data in the table. 4.

4. Charge the batteries until abundant gas evolution occurs in all batteries of the battery, and the voltage and density of the electrolyte remain constant for 2 hours. Monitor the voltage with a voltmeter of accuracy class 1.0 with a scale of 0.02 V. , for a battery with hidden jumpers - a voltmeter with a 30 V scale with a division value of 0.2 V.

5. During charging, periodically check the temperature of the electrolyte and make sure that it does not rise above 45°C in cold and temperate climate zones and above 50°C in hot and warm humid zones. If the temperature is higher than the mentioned values, The charging current should be reduced by half or the charge interrupted for the time necessary to reduce the temperature to 30-35°C.

6. At the end of the charge, if the density of the electrolyte, measured taking into account the temperature correction according to the table.1,

will differ from the norm indicated in the table. (column 4), adjust the electrolyte density by adding distilled water in cases where the density is above normal and by adding an acid solution with a density of 1,400 g/cm3 when it is below normal.

After adjusting the electrolyte with water or acid solution, continue charging for 30 minutes. for complete mixing of the electrolyte

After adjusting the electrolyte density of the batteries, turn off the charge and let stand for another 30 minutes. no current.

Then measure the electrolyte level in all batteries of the battery. If the electrolyte level is lower than normal, add electrolyte to the battery with the same density as indicated in the table. t

(Column 4),

if

the electrolyte level is above normal, remove the excess electrolyte with a rubber bulb. After charging, the batteries are put into operation.