Everyone who decided to purchase their own car was faced with the problem of choosing a transmission. In addition to considering the main points - choosing a brand, color, body type - buyers are faced with the question: manual or automatic - which is better? There is no definite answer, because the choice of gearbox depends on many factors. A thorough analysis of the operation and repair of both types of transmissions will help you determine your preference.

Manual transmission knob

Is it possible to convert an automatic transmission to a manual transmission and how to do it yourself

Therefore, if you experience any problems with gear shifting, you should contact a car service center. It is possible that everything can be solved by repairing the manual transmission rather than replacing it.

Replacing a manual transmission

As a rule, oil leakage and extraneous noise in the form of grinding/crunching do not indicate that the car needs a new gearbox. However, the presence of the described phenomena (even if they do not appear often) indicates the need for urgent contact with an appropriate specialist. It will not be possible to repair a manual transmission only if extensive damage to the components of the transmission is detected. To have fewer issues with this device, you need to diagnose the manual transmission in a timely manner, despite the fact that a manual transmission is more reliable and requires less attention than an automatic one.

Replacing a manual transmission: the price of the issue

Installing/removing the gearbox will cost around $100.

A manual transmission will cost the car owner from $4,000, the old one is about 2 times cheaper. In view of the fact that natural exhaustion of the resource of this device is quite rare, you can consider the option of replacing the old manual transmission with a used one (condition: the shafts and gears are in good condition). However, in a used gearbox it is recommended to replace the bearings and crankcase.

As a result, the total cost of replacing a manual transmission (provided that the device is purchased new) is at least $4,100.

Where to replace the manual transmission?

You won't be able to replace the manual transmission yourself. Firstly, adaptations are necessary, since in practice this event is technically complex. For example, to remove a manual transmission, you will need to lift the car. Secondly, only after removing the box itself and visual inspection/diagnosis can a plan for further action be drawn up. Thirdly, it is important to contact specialists; this will require removing the clutch, axle shafts, etc.

Replace a manual transmission with an automatic one

Most specialists and car enthusiasts consider the procedure of replacing a manual transmission with an automatic one to be a completely unnecessary exercise. First of all, it's expensive. Installing an automatic transmission instead of a manual one will require replacing/mounting a number of important components: the automatic transmission itself, cardan shaft, pedal assembly, rocker, flywheel, wiring system, etc. Secondly, it is believed that there are many more problems with an automatic transmission than with a manual transmission. Another argument is that technical tuning can cause unpredictable consequences. However, their occurrence can be avoided if a new unit is installed at a service station.

Replacing the gearbox: manual transmission with automatic transmission

Having studied the information on replacing an automatic transmission with a manual transmission, you might think that the reverse process of replacing a transmission with an automatic transmission follows the same principle. Let us immediately note that in practice this is not the case.

The process of replacing a manual transmission with an automatic one is much more labor-intensive and expensive. Dismantling the gearbox and all equipment is the beginning of a long and technically complex operation. In order to change a manual transmission to an automatic transmission, it is necessary not only to replace the instrument panel and wiring, but also to purchase a large number of spare parts.

A basic list of required parts includes:

- Automatic transmission, automatic transmission radiator and hydraulic pipes to the radiator;

- Automatic transmission selector with cables, one or two “braids” of wires (virtually a complete replacement of the wiring);

- control unit (ECU) for automatic transmission, relays, fuses;

- instrument panel, speedometer sensor;

- reverse “frog”, pedal assembly, starter;

- mounting pads (not always, depends on the car);

- cardan (not always, depends on the car);

- torque converter (if not included with automatic transmission).

The order of technical operations performed when replacing a gearbox with an automatic transmission:

- The manual transmission is dismantled and the clutch assembly parts are disconnected.

- Disconnecting the rocker and dismantling the pedal assembly.

- The flywheel is removed, after which the cardan or axle shaft is dismantled (depending on the drive).

- Disconnect and remove the hydraulic pipes of the clutch drive, then install the disk with the crown on the crankshaft.

- The automatic transmission cooling radiator is installed and the rear support for the internal combustion engine is additionally installed.

- The starter and cardan are replaced (if necessary, depending on the car).

- Replace all electrical wiring connected to the instrument panel with replacement of the instrument panel itself.

- The ECU for the automatic transmission is being installed.

Gear repair

TO

category:

Repair of tractors and cars

Gear repair

Next: Repair of block and cylinder liners

When teeth are worn out or damaged to the point of rejection, gears are relatively rarely restored. The processes for restoring teeth are very complex and are used only in large specialized enterprises. In the transmissions of some tractors and automobiles, individual gears are made in the form of rings attached to the hubs with rivets. During operation, the teeth of the rims wear out and the rivets weaken. Such gears are restored by replacing or re-riveting the crowns. In the moving gears, the ring grooves for the shift forks wear out.

Restoration of gear teeth. Gears with worn or damaged teeth are restored by gas or electric arc surfacing, pressing and replacing part of the part.

Restoration by surfacing. When surfacing teeth, electrodes are used that provide high strength of the deposited layer without the use of heat treatment. It must be remembered that surfacing teeth rarely gives satisfactory results, so it is used in extreme cases and mainly for surfacing teeth worn at the ends.

Restoration by indentation. By pressing, small gears are restored with the necessary supply of metal on the crown. The gear is heated to a temperature of 900...950 °C in a neutral environment (in a used carburizer or in a salt bath) and using a special matrix and punch under a press or hammer, annular grooves are extruded from one side or both sides, increasing the outer diameter. After indentation, the part is cooled in sand and then subjected to mechanical and heat treatment. They bore the hole, trim the ends of the gear, grind the cylindrical surface, cut the teeth and heat treat it like a new gear.

Replacing part of a part. This method restores gear blocks or moving gears (carriages) with two or three rims, one of which must be discarded, and the rest are in good condition.

The worn crown is removed by electric spark treatment with a tubular electrode tool or annealed and ground to the required size D, which makes it possible to obtain a thickness of the new crown B that is 2-2.5 times greater than the height h of the tooth. The pressed crown is secured with two or three screws and welded.

Replacement and re-riveting of gear crowns. The rivets of the crowns with worn teeth are cut off, and the crowns are pressed and replaced with new ones. If the teeth are worn on one side, the symmetrical rims are rotated 180° and re-attached to the hub to operate with the unworn side of the teeth. At their ends, on the engagement side of the movable gear, a chamfer is removed. To facilitate pressing, the crowns are heated in water or, better yet, in oil to a temperature of 95...100 °C. When pressing, the grooves for the rivets on the crown and the hub match with an accuracy of at least 0.1 mm. If, when attaching narrow rims to the hub, during installation it is possible to obtain a ratio of the length of the rivet to its diameter of no more than 4, then it is better to carry out the riveting in a cold state.

Wide crowns are secured with hot rivets heated to forging temperature. Riveting is carried out using hydraulic presses, devices or manually. The heads of the rivets must fit snugly against the end surfaces of the crown and hub. The axial runout of the crowns assembled with the hubs should not exceed 0.25 mm.

In crowns left without repair, loosening of the rivets and seating on the hub is not allowed. Loose rivets are cut down and new ones are installed. Tightening of rivets is not allowed.

The ring with a weakened fit is removed, the seat is restored by leaving or surfacing and processed to a size that ensures a press fit on the hub.

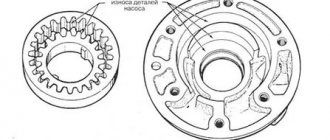

Rice.

Replacing a manual transmission with an automatic transmission and vice versa: features

The main parts, the restoration of which during a major overhaul of a car presents known difficulties, are gears. Gearbox gears for Ural-4320 vehicles are made primarily from alloy steel and are heat-treated. The following steels are used as materials for the manufacture of gears: 35 X, 40 X, 12ХНЗА, 12Х2Н4А, 25ХГТ, 25ХГМ and for low-critical parts carbon steel 20. The gears of Ural-4320 automobiles are made from steels 35X and 40Х.

Gears made from these steels are subjected to heat treatment: cyanide plating to a depth of approximately 0.6–0.8 mm, oil quenching and tempering to tooth hardness HRC 48–53 and splines HRC 20–40.

The maximum wear of gearbox gear teeth is allowed up to 0.22-0.30 mm in tooth thickness and 15% along its length. Fine conchoidal rash is allowed up to 30% of the working surface of the teeth.

Restoring worn gear teeth and splines is a somewhat difficult task, since all gears are subject to rather complex heat treatment.

The most common causes of automatic transmission failures

Gearbox slide

The problematic mechanism of old-type automatic transmissions, which have a mechanical connection between the transmission and the gear selector, is the lever linkage. The presence of such a problem is indicated by the appearance of difficulties in shifting gears of an automatic transmission. In this case, to eliminate malfunctions, you will need to replace both the lever links and the selector itself. Most models have good access to the problem area, so dismantling the gearbox to replace worn equipment is not required. This greatly facilitates repair work.

Low oil level and presence of smudges on the device

A frequent “symptom” of an automatic transmission malfunction is oil leaks on the device body, indicating wear of the sealing gaskets. In this case, it is advisable to replace them yourself (this procedure will not cause difficulties) and change the oil in the automatic machine. Car enthusiasts are advised to visually inspect the gearbox for leaking oil at least once every 2 thousand kilometers.

Transmission control unit

If malfunctions occur in the operation of the unit, you can notice that the speed switching does not occur in the usual mode, but at overestimated or, conversely, underestimated speeds. At a certain moment, the machine may be completely blocked. Repairing the control unit consists of replacing the problematic mechanism and thoroughly inspecting the electrical part of the gearbox.

Worn gearbox

Metal shavings on a magnet in the oil pan

Broken oil pump

How to replace a gearbox

Therefore, advanced auto repair plants, equipped with modern gear shaping and hobbing machines, which made it possible to abandon labor-intensive and qualitatively ineffective methods for restoring gears, switched to their production. Advanced repair plants also have the necessary equipment for heat treatment.

As for repair shops, here, due to the small-scale nature of production, they resort to restoring gears by installing additional parts.

The gearbox shafts are made from the same alloy steels as the gears. The drive and intermediate shafts of the Ural-4320 vehicle gearbox are made of ZOHGT steel, carburized to a depth of 0.7-1.0 and 0.5-0.9 mm, respectively, hardened and tempered to a hardness of HRC 56-62.

The driven shaft is made of 40X steel and is case hardened. hours to a depth of 1.5-4.0 mm, the hardness of the surface-hardened layer is HRC 50-62 and the non-hardened part HR C 28-33.

Defects in gearbox shafts include wear of the bearing journals and wear of the splines in the primary and secondary shafts.

Wear of the bearing journals for rolling bearings is allowed on average within the range of 0.02–0.03 mm. In some cases, wear of the secondary journal

shaft for a roller bearing is allowed up to 0.04 mm. Spline wear is allowed within 0.12–0.16 mm.

Restoration of worn shaft bearing journals can be carried out by: electric pulse surfacing, chrome plating and iron plating. Automatic surfacing under a layer of flux is less practical here due to the small diametrical and linear dimensions of the journals and the amount of their wear, on average not exceeding 0.05-0.10 mm. With such a small amount of wear, in order to obtain the most uniform structure of the deposited metal, the journals before surfacing pre-polished. Preliminary grinding of the journals eliminates traces of metal corrosion and various surface contaminants and thereby contributes to higher adhesion strength of the surfacing to the base metal. Surfacing is carried out using OVS or P-1 wire with a diameter of 1.6–1.8 mm to a thickness of 0.6–1.0 mm, depending on the amount of wear of the journals.

The journal under the flywheel bearing in the drive shaft and the journal under the roller bearing in the driven shaft are subject to the greatest wear. The surfacing mode of the journals is approximately the same and can be taken as follows: U = 12-13 V; nd = 4-6 rpm; υnp = 1.3 m/min, surfacing step (feed of surfacing head) sn = 3 mm/rev, inductance 6 turns RSTE-34; fluid flow 0.5 l/min.

After surfacing, the journals are grinded, initially rough, then finished to the initial dimensions, maintaining the surface cleanliness according to the drawing. The insignificant amount of wear on the journals allows us to consider restoring them with electrolytic coatings as quite rational, especially in conditions of centralized restoration of parts.

Chrome plating and iron plating are applicable to all gearbox shaft journals, with the exception of journals associated with roller bearings.

Restoration of gearbox shaft journals was previously carried out by manual electric arc surfacing using electrodes of type 03N-300, U-340pb, and such journals as the drive shaft guide under the flywheel bearing and under the roller bearing of the drive shaft - and by installing additional parts.

If there are burrs and nicks on the splines, they are manually cleaned with a carborundum block or an emery stone.

Restoration of splines in case of significant wear is carried out by surfacing under a layer of flux, and in the absence of it - by manual electric arc surfacing.

During the surfacing process, slag is removed after each bead is applied.

When surfacing under a layer of flux, electrode wire Sv-ZOKHGSA with a diameter of 1.5-2.0 mm is used. Flux - AN348A or OSTS45.

Manual electric arc surfacing of splines can be used when the enterprise does not have an installation for automatic surfacing under a layer of flux. In this case, manual electric arc surfacing is carried out using U-340pb or 03N-300 electrodes. The hardness of surfacing with these electrodes ranges from HB 275 to 325.

It is advisable to carry out surfacing with a direct current arc with reverse polarity. Then k is chosen depending on the diameter of the electrode.

After surfacing the splines, the shaft is checked for runout and, if necessary, straightened, and then machined. The technological process of machining splines depends on the method of centering the mating part, depending on the mating part. There are three methods of centering: along the outer diameter, along the inner diameter and along the side surfaces of the splines.

By centering the mating part along the outer diameter of the splines, the spline roller receives the exact size after finishing turning or grinding on a cylindrical grinder. The internal diameter of the splines with this centering method has a rough tolerance and therefore, apart from milling, does not require any other processing.

When centering along the inner diameter, the dimensions of the 1st and the width of the splines have rather narrow tolerances, and as a result, processing of the splines is more complex than when centering along the outer diameter.

Regardless of the centering methods, after surfacing the splines, the part is turned on a lathe, then the splines are cut.

The most productive and accurate method of cutting splines is cutting them by rolling them on gear hobbing machines using hobs. With this method, the 1-by-1 cutter, in addition to rotational movement, has longitudinal movement along the axis of the roller being cut.

In the absence of a gear cutting machine, splines can be cut using the division method on horizontal or universal milling machines. The part is divided into the required number of splines using a dividing head or dividing device.

Due to the rather narrow tolerance limits, it is usually not possible to machine widthwise splines in one pass. Therefore, initially, the side surfaces are rough-processed with two disk cutters, leaving an allowance for finishing milling in the range of 0.8-1.2 mm. Finish milling of the internal surface is carried out with a shaped cutter or a disk cutter sharpened according to a template.

Finish milling of the side surfaces of the splines is carried out with two cutters, the distance between which must correspond to the width of the splines according to the drawing. After cutting, the splines are subjected to heat treatment in relation to the grade of steel from which the part is made.

Thus, spline rollers made of 40X steel are hardened at a temperature of 830–850° C. Cooled in oil and tempered at 250–300° C. Cooled in air. It is advisable to carry out heating for quenching and tempering in a salt bath.

When heated in fiery furnaces, scale forms on the parts, so it is not always possible to maintain the size according to the drawing. It is impossible to carry out finishing milling to obtain the nominal size after heat treatment due to the high hardness of the splines. In this case, grinding of the splines is necessary. A grinding allowance of 0.20-0.25 mm must be taken into account when rough milling splines.

Grinding along the outer diameter, in the case of centering along it, is carried out on cylindrical grinding machines with the part usually installed in the centers. Other centering methods involve grinding along the internal diameter and along the side surfaces of the splines. If special machines are available, grinding can be done using rattling wheels.

in one operation.

Despite the high productivity, this method requires frequent dressing of the grinding wheels due to uneven wear. When grinding spline rollers, the surface of the inner diameter of the roller is first ground in two separate operations, and then the sides of the spline. After machining, the spline rollers are inspected. The outer diameter is checked with a limit clamp, and the internal diameter with a micrometer or a special clamp, or even better, with an indicator clamp. The width of the slot is checked with limit brackets, and the profile of the internal diameter with a template. Checking the runout along the inner diameter and taper is carried out with an indicator.

Publication date: 2014-10-20; Read: 1545 | Page copyright infringement

What needs to be done to avoid problems with automatic transmission?

Like any other mechanism, an automatic transmission requires compliance with basic operating rules. Its rapid wear can be easily explained by irregular replacement of transmission oil and, as a result, rapid heating of overloaded components of the device. Elements that lack oil lubrication wear out quickly and lead to serious breakdowns. In addition, old oil negatively affects the operation of solenoids, the dismantling of which will cause great difficulties - it is almost impossible to get to them without removing the automatic transmission.

In harsh weather conditions, the automatic transmission requires thorough warming up, otherwise the mobility of transmission parts will be impaired. An aggressive driving style also negatively affects the operation of the automatic mechanism: due to the long operation of the engine at high speeds, the process of burning out the clutches begins. You need to change gears and accelerate smoothly in order to significantly increase the service life of the transmission mechanism.

Replacing worn parts in itself is not particularly difficult. But the main problem that repairmen will face is the need to remove the automatic transmission from the car. This can only be done using a special device. Removing the gearbox will allow auto mechanics to open it and determine what is broken, after which they will need to carry out high-quality repairs to eliminate all faults. Despite the high cost of automatic transmission repair services (this is explained by the labor-intensive process), you cannot save on the transmission. Once you figure out, say, a simple oil leak, you will save your car from major repairs in the future.

| Automatic transmission malfunctions | Ways to eliminate them |

| Car slipping at first speed. At the same time, reverse speed works without problems | The clutch piston ring and piston cup need to be replaced. The torque converter valve must be cleaned of dirt. |

| The first speed works, the rest (including reverse) do not function | The friction disc and worn clutch piston need to be replaced. It is worth checking the condition of the coupling ring seals; if they are broken, replace them |

| The car is not moving. Reacts to gear changes with a strong jolt | The torque converter should be replaced. You should also check the transmission oil level and add it if necessary. The oil filter may have become unusable and needs to be replaced. |

| Only 3rd speed works | It is necessary to replace the clutch piston cuff and friction discs. Check the hydraulic unit valve for contamination. If the above steps do not help, the car must be taken to the nearest service center. When the emergency mode of the gearbox is engaged, there is a possibility of serious damage being detected |

| The car's reverse gear does not work | It is necessary to check the condition of the brake band, as well as the entire braking system of the car. |

| The car does not react at all to changing gears. No shock or movement | The transmission oil may have run out. Check the level and top it up if necessary. Clean the filter mesh and valve body valve from contamination and check the condition of the solenoids. |

| When driving a car, vibration and a strong rumble of the automatic transmission are noticeable. The more revolutions, the louder the noise | Bearings need replacement |

| The usual speed shift step has gone astray | Adjust the throttle cable and clean the filter from dirt. If the problem persists, replace the throttle valve. |

| During a long climb, the car noticeably slips; the automatic transmission engages in a lower gear. | Low oil level can cause a similar problem. You should also inspect and then replace the brake band, friction discs and clutch. Oil pump needs replacement |

| Engaging first gear leads to the car slipping; as the speed increases, the slipping ends | The automatic shaft is slipping. The turbine wheel hub spline needs to be replaced. The piston cuff has ruptured |

| Changing gears causes the car to slip | Clean the filter and change the transmission oil. If that doesn't help, then you need to replace the oil pump. |

| Each speed change is accompanied by uncharacteristic shocks | Friction discs and brake band need to be replaced |

| An unheated car moves without visible malfunctions, but as soon as the transmission oil heats up, the vehicle slips | An oil change is necessary: while it is in a “cold” state, it compresses the friction discs more tightly. Heating reduces its pressure and viscosity, leading to similar problems |

| When you sharply press the gas pedal, the automatic transmission does not switch to a lower gear, and the engine speed does not increase | The malfunction lies in the operation of the propulsion system. You must immediately contact a service center |

| During a visual inspection of the car, iron “shards” with a diameter of 1 mm were found in the pan of the vehicle | The planetary gear fails. Part replacement required |

| The transmission oil foams and its color changes to an unnatural one. | Water got inside the machine, the oil needs to be changed |

| Turning on the speed causes the engine to turn off; when you hold the gas pedal, there is movement | The torque converter is faulty. It needs to be replaced |

| There are aluminum “shards” in the pallet | Replacement of planetary gear and sliding bearing is required |

| On the pallet you can see the plastic | It is necessary to inspect all plastic components of the automatic transmission |

| When the vehicle moves, a metallic grinding noise is noticeable | The differential gears and bearings have failed. They need to be replaced |

| When inspecting the vehicle, magnetized rollers may be found in its tray. | This malfunction indicates the destruction of the roller bearing |

The appearance of an incomprehensible noise in the transmission, vehicle slipping, noticeable vibration and significant deviations from normal “behavior” indicate the presence of automatic transmission faults in the vehicle. If the first signs of a breakdown appear, it is advisable to contact a service center for help.

Long-term use of a car with a broken automatic transmission will lead to complete blocking of the transmission, and after that the driver will have to pay not only the cost of repairs, but also the services of a tow truck.

“Electronic” automatic transmission problems

Malfunctions often appear in the electronics of the automatic transmission, but, fortunately for car owners, when they are detected, dismantling and disassembling the automatic transmission is not required. The main “electronic” problems include:

- Instability of the “automatic” sensors: the car either periodically enters emergency mode (while driving) and exits it on its own, or goes into emergency mode completely and does not exit it even after the power unit is turned off.

- Malfunction of the control unit: the gearbox does not exit emergency mode for a long time.

- A short circuit in the wiring that causes a lack of response to automatic gear shifting. The car is in constant emergency mode or periodically exits it, but does not respond to the driver’s actions.

- Faulty solenoids, electric pressure regulator: the car periodically “forgets” to change gears, shocks and mechanical grinding are noticeable when shifting, in some cases the vehicle goes into emergency mode and exits it on its own.

All of the listed automatic transmission malfunctions do not require “surgical intervention” by auto mechanics, i.e. To diagnose them, you do not need to disassemble the automatic transmission. It is enough to use a special scanner or measure electrical parameters (inductance, electrical resistance, etc.)

Inability to change gears

In some types of breakdowns, the gearbox does not change gears. It is difficult to figure out what the reason is, having only indirect signs, but it is possible. So, the automatic transmission does not include speed, most often for the following reasons:

- Low transmission oil level. A low oil level is indicated by the car slipping at the beginning of movement, jolts when shifting gears, and a complete lack of movement of the vehicle. In combination with a faulty torque converter, the lack of the required amount of oil can lead to destruction of the main elements of the transmission mechanism. The algorithm of actions is very simple: at the first signs of malfunctions, add oil, change the filter; in case of complications, seek help from highly qualified specialists.

- Wear of friction discs. The wear of these elements is indicated by the incomprehensible behavior of the car: either it moves forward, but there is no reverse gear, or everything happens exactly the opposite - there is a reverse gear, but there is no forward movement. In addition, slippage may occur after the transmission fluid heats up. Friction discs, when they fail, form dust, which settles on the automatic transmission filter, clogs it, causing a drop in main pressure.

- Broken brake band. The brake band can also cause serious problems in the operation of the automatic transmission. To diagnose wear of this element, it is necessary to carry out a visual inspection and inspection of the entire brake system. The driver must monitor the condition of this mechanism to maintain the required level of vehicle safety.

- Shift valve sticking. This malfunction can be easily eliminated - just clean the valve from dirt and install it back.

- Torque converter malfunction. The torque converter is a single unit that cannot be disassembled. If one of its components fails, then the entire device must be replaced. If the vehicle is used correctly, the torque converter will last 150-200 thousand kilometers.

Removing gearboxes

Removal of the variable transmission may be necessary if it is replaced or repaired. The reason for diagnosing the gearbox may be foreign noise, oil leakage, difficult or spontaneous switching of speed modes. The reason is:

- lack of oil;

- wear of oil seals, gaskets, couplings or synchronizer blocking rings;

- deformation of the shift lever or forks, jamming of the spherical joint;

- clutch malfunction.

The solution is to replace the worn parts, but the gearbox will have to be removed. In car services, the cost of removing a transmission varies slightly, but since this operation is troublesome, you need to select a technical center with good specialists.

Before removing the car's gearbox, the oil is drained from it, even if disassembling the gearbox itself is not planned, but, for example, the clutch will be replaced. On some cars, before you can get to the gearbox, you will need to remove the engine or front axle.

Removing a variable transmission from a front-wheel drive vehicle

To remove the transmission from a front-wheel drive vehicle, the first step is to disconnect the drives themselves. On most cars, this is enough to remove the ball joint mount and pull out the drive grenade. But it happens that the drive has a detachable connector and you only need to unscrew a few nuts. On some cars, you can dismantle the drive by knocking out the tubular fixation pin. In short, each model has its own specifics. Prices for removing the gearbox from such cars at service stations are usually higher than for the gearbox of rear-wheel drive cars.

Removing the gearbox from a rear-wheel drive car

On rear-wheel drive vehicles, the work is approximately the same. If a manual transmission is installed, then before removing the gearbox, you always have to disassemble the selector console in the car interior and remove the lever. Next you just need to remove the cardan outboard bearing and you can remove the gearbox. In the case of an automatic transmission of a car, you must first remove the fluid coupling, or rather, unscrew all the bolts that secure it to the flywheel, and then remove it together with the gearbox.

Removing the transmission from a four-wheel drive vehicle

On four-wheel drive vehicles, the engine is often located along the body. In this position, after removing the gearbox, there is a possibility of the motor being skewed.

Operation of the box

How to use the automatic transmission correctly? Two pedals and many transmission modes can plunge an inexperienced driver into a stupor. At first glance, everything is simple, but there are nuances. Below are explanations of how to use an automatic transmission correctly.

Modes

Basically, the automatic transmission has the following positions on the selector:

- P is the implementation of a parking lock: locking the drive wheels (integrated inside the gearbox and does not interact with the parking brake). An analogue of putting a car into gear (“mechanics”) when parking it;

- R - reverse gear (it is forbidden to activate while the car is moving, although locking is now applied);

- N — neutral transmission mode (activation is possible during short-term parking/towing);

- D — forward gear (the entire gear row of the box is used, sometimes the two highest gears are cut off);

- L - activation of the low gear mode (low speed) for the purpose of moving off the road or on it, but in difficult conditions.

Auxiliary (advanced) modes

Present on boxes with wide operating ranges (the main modes may also be marked differently):

- (D) (or O/D) - overdrive. Economy and measured movement mode (whenever possible, the box switches upward);

- D3 (O/D OFF) - deactivation of the highest stage for active driving. It is activated by the braking of the power unit;

- S - gears spin up to maximum speed. There may be the possibility of manual control of the box.

Take into account:

Compared to a manual transmission, an “automatic” engine brakes only in certain modes; in the rest, the transmission slips freely through the overrunning clutches, and the car coasts.

Example - manual transmission mode (S) provides for motor deceleration, but automated mode D does not.

Gearbox repair and maintenance

Repairing a transmission is a difficult task. It is better to visit service stations more often, where they offer professional services that are worth evaluating.

Car breakdowns often worry drivers. Since ancient times, people have been trying to cope with them on their own, but they almost never succeed. Today it is easier to visit a service station one more time so as not to encounter difficulties. A professional mechanic will repair the gearbox much faster and with better quality, so there is no need to refuse his services. But first you need to consider the reasons pushing for such a decision.

Sign up for a car service

It is quite possible to sign up for this service at a car service center without a visit. Registration is carried out at technical centers

- by phone

- through the website "101 car service"

Extensive experience and a responsible approach to business allow us to carry out repair work “excellently”. Argon welding of a car gearbox is a complex technological process that involves the use of specialized equipment. Only professional specialists from our company with appropriate qualifications can perform it efficiently.

Repair after diagnosis

First of all, the workshop carries out a complete diagnosis of the car. Unfortunately, some drivers make the serious mistake of mistaking another system for a gearbox failure. They start repairs without realizing that they are wasting time and energy. Moreover, after incorrect assembly, new faults often appear.

Carrying out computer diagnostics now allows you to instantly find any breakdowns. Because of this, it is carried out before any repairs. Today, professional equipment is available at every service station, so services have become available to all motorists. Still, recognizing a gearbox breakdown is not easy, which means it’s impossible to do without the necessary data.

Even professionals cannot get involved with automatic transmissions without computer diagnostics.

Automatic transmission repair, its main features.

You can order professional repair of automatic transmissions of any make and model. We work with all foreign cars supplied to the Russian car market. Manufacturers initially set the working life of the automatic transmission to no more than 150,000 km, but in Russian conditions the service life is significantly reduced due to rough roads, poor quality oil and some other factors.

Automatic transmission repair begins with mandatory computer diagnostics: in some cases, the cause of the problem lies not in the transmission itself, but in problems with the electronic control unit. The diagnostician checks the ECU and determines the true cause of the problem. The following symptoms most often indicate automatic transmission malfunctions:

- An alarm appears on the dashboard. The indicator cannot be ignored! Be sure to carry out diagnostics.

- The appearance of slipping, the occurrence of shocks in the box at the moment of gear shifting.

- Violation of reverse gear engagement.

In the future, if urgent measures are not taken. The automatic transmission will begin to fail and eventually fail completely.

Electrical, mechanical and hydraulic failures are possible. In the first case, the sensors of the control system fail, malfunctions of the electronic control unit or mechanical damage to the wiring are possible. Also common causes of breakdowns are wear of the forward shaft or overrunning clutch, disruption of the friction elements, damage to the torque converter, and rupture of the brake band.

Automatic transmissions require prompt repairs, since one malfunction quickly leads to disruption of other parts and worsening of the situation. If you postpone repairs until later, you will have to change more parts in the future. In difficult cases, it is necessary to replace the automatic transmission with another reconditioned or used one. It is possible to accurately determine the cause of the problem only with professional diagnostics: do not trust this work to generalists, use our help from qualified diagnosticians and car mechanics.

When repairing with the installation of new parts, our customers are provided with a warranty for a period of 3 to 24 months. We guarantee the quality of each operation; the repair ends with a full check of the box’s functionality in all modes.

The cost of repairs has decreased

Previously, drivers tried to carry out repairs themselves due to high financial costs. They could not afford the services of specialists, so they understood individual components and systems using instructions. Now the price of gearbox repairs no longer scares anyone. The opening of numerous service centers and the availability of necessary equipment have affected the cost.

It is important that a few years ago, human costs increased due to the high price of spare parts. Now you don’t even need to order them, since they are freely distributed through catalogs on websites. If necessary, just select the required part, and then pick it up at the pickup point or wait for the courier. Due to this, the costs of eliminating all gearbox faults have been significantly reduced.

You can read about engine repair here. You can learn about the features of diagnosing and repairing the brake system from this article.

Free evacuation and diagnostics for major repairs of automatic transmission, variator, DSG!

Our Premium COLOR workshop carries out diagnostics and repairs of gearboxes for all brands and models of cars. This is one of the complex and important components of a car: the gearbox is an integral part of the transmission and is responsible for changing the gear ratio and transmitting torque from the engine to the drive wheels of the car. It also provides the ability to move in reverse. The gearbox is a reliable unit, designed for long-term use, but over time, parts wear out and require replacement.

For any problems with the gearbox, the best solution is to contact our specialized car service center. The workshop offers gearbox repairs of any complexity. Experienced specialists and car mechanics will quickly and professionally cope with the task.

What are the most common causes of gearbox malfunctions?

Long-term use of the gearbox is only possible with timely maintenance, compliance with the manufacturer's maintenance recommendations, and careful handling of the vehicle.

Transmission repair is most often required for the following reasons:

- Aggressive driving style and violation of vehicle operation rules.

- With constant movement in high gears and low speeds, parts wear out faster, as a result the gearbox very soon fails and requires expensive repairs.

- Violation of the rules for servicing the gearbox. The manufacturer regulates the timing of maintenance, and increasing the intervals negatively affects the condition of the box.

- Poor quality gear oil. An attempt to save on lubricants leads to increased friction in the box and premature wear of parts. As a result, savings turn into large additional expenses.

- Poor quality spare parts and unprofessional intervention. You should not try to carry out repairs on your own or entrust them to non-specialists: modern gearboxes are complex mechanisms that require special diagnostic equipment and high-quality spare parts.

If you have any symptoms of a gearbox malfunction, do not wait for a more serious breakdown, but immediately contact our diagnosticians and specialists. The Premium COLOR workshop is a specialized car service where you can order repairs of manual transmissions, automatic transmissions, gearboxes, variators, robotic transmissions and get excellent results in the shortest possible time.

What are the most common signs of a faulty transmission?

There are several most common signs indicating a transmission malfunction. Even before diagnostics are carried out, the car owner should pay attention to the following alarming symptoms:

- The appearance of extraneous noise in the gearbox. Creaking, knocking, noise when changing gears may indicate faulty bearings and gear wear; the exact cause of the problems can only be determined during diagnostics.

- Difficulty when changing gear. If they shift too hard, this usually indicates a malfunction of the synchronizers or a lack of oil in the gearbox crankcase. It is necessary to contact the workshop as soon as possible to avoid serious damage.

- Spontaneous gear shutdown. At the same time, the car’s handling deteriorates, in addition, there is a threat to other components, so repairs cannot be postponed.

- The appearance of oil leaks on the gearbox housing. It is necessary to identify and eliminate the cause of the leak; it is either torn gearbox seals or a damaged transmission housing.

In the workshop, repair of automatic transmissions and other types of gearboxes equipped with an electronic control unit begins with initial computer diagnostics. Using the ECU error codes, a diagnostic specialist will determine the exact location of the fault and calculate the best option for eliminating it.

Diagnostics are also carried out in natural conditions - on the move with the engine turned on - an on-site test drive. When switching modes, the diagnostician determines exactly where the problem occurs and which parts are not doing their job. After diagnosis, the driver is provided with complete information about box faults and the need to replace specific parts, as well as the cost of upcoming repairs.

It's not easy to change the gearbox

Experienced drivers are confident that rebuilding a transmission is a simple task. Perhaps they can easily cope with the design of their own old Zhiguli car, but any new car will make them think. Indeed, people rarely encounter various breakdowns, so they don’t even imagine how complex foreign cars are.

At service stations, technicians quickly cope with such tasks, but they still agree that there are difficulties. At the same time, they even talk about which cars create the most problems. Of course, automatic systems still require special training. Some specialists are still unable to cope with them, trying to find the next breakdown. Accordingly, drivers should not try to carry out repairs themselves.

Automatic transmission is a complex system that requires professional skills. Moreover, execution of work, again, is possible only after computer diagnostics. It is not surprising that experienced motorists prefer to refuse to do their own repairs. They understand very well what serious mistakes are made out of ignorance.

DSG repair, features of robotic gearbox.

DSG repair is periodically required by owners of the latest models of Audi, Volkswagen, Skoda, Seat cars; they are equipped with a 6 and 7-speed gearbox. Its name stands for Direkt Schalt Getrieb - direct switch box.

DSG repair may be required due to untimely maintenance and violation of operating rules; in addition, such a box has several vulnerable spots that cause breakdowns.

The German robotic gearbox has a very complex design, which leads to rapid wear of some parts. DSG repair may be required due to damage to the multi-plate friction clutch, wear of the solenoids, problems also arise due to failures in the electronic control unit.

DSG repair is a complex process that begins with computer diagnostics. A diagnostic specialist will determine the cause of the problem and faulty parts, disassemble, troubleshoot and replace, after which the functionality of the box will be completely restored. Our car mechanics successfully cope with even very complex cases of DSG repair, which will allow you to quickly and inexpensively restore your car. You can purchase all the necessary components at cheap prices.

DSG repairs are completed by issuing a long-term warranty card. We guarantee the quality and reliability of the installed parts.

Maintenance will increase service life

In addition, there is gearbox maintenance, which drivers often forget about. After all, you can freely avoid frequent breakdowns by regularly performing certain actions or turning to specialists for help. This means that we need to consider them in order to give advice to car enthusiasts.

- Gearbox flushing;

- Draining the sludge;

- Clutch adjustment.

Today, at service stations, technicians perform the necessary actions in just a few minutes. There will be no delays, so don't forget the importance of maintenance. It eliminates premature damage, helping a person save considerable money. So it’s time to consider each type of work in detail, giving its general description.

Flushing the gearbox

Experts constantly talk about flushing the transmission, because many motorists forget about it. They want to save money, but such actions can only be accomplished by draining new industrial oil. To do this, you need to fill the gearbox again, and then immediately drain it to remove the smallest specks. They always pack inside the casing, so work is necessary.

By refusing to flush, the driver brings the moment of breakdown closer. The surface of the gears gradually begins to deteriorate, which means that at some point the gearbox will fall apart. Even the remains of old oil are dangerous.

Draining the sludge

Experts also advise draining the sediment regularly. The oil is gradually processed and needs to be changed. A car enthusiast can do this without outside help; it is not necessary to go to a service station. Moreover, it is better to forget about saving and regularly perform the necessary actions.

By draining the oil sludge, the driver removes unnecessary impurities from the box. They greatly increase the wear of individual parts, gradually leading to serious damage. Replacing parts will require money, and self-service will only cost the cost of oil. Because of this, you should not neglect the advice of professionals. With their help, it will be possible to maximize the service life of the gearbox.

CVT repair, features of repair and diagnostic services.

The Premium COLOR workshop carries out diagnostics and repairs of a variator (CVT) - this is a type of automatic transmission that allows you to smoothly change speeds in automatic mode. The variator ensures smooth gear shifting, the absence of jerks guarantees driving comfort. However, this type of box requires regular professional maintenance and high-quality troubleshooting.

The main reason why CVT repair is required is a violation of the operating rules of the CVT gearbox. It may be associated with unprofessional maintenance, untimely oil changes, low quality oil, and aggressive driving style.

Natural wear of parts occurs after approximately 120-150 thousand kilometers, but unfortunately, most often breakdowns occur faster.

Repair may be required due to electrical or mechanical problems with the variator. If the problem is due to a problem with the electronic control unit, a Service required icon appears on the dashboard, indicating that urgent service is required. If the gearbox overheats, the Slow down signal will indicate that the permissible temperature has been exceeded (in this case, we will install an additional cooling radiator for you).

Electronic system faults can be determined using computer diagnostics. The scanning device generates error codes; special equipment recognizes the error code and prints the cause of the problem on tape. The gearbox repair workshop is equipped with everything necessary to accurately identify and determine faults in the electronic gearbox system.

In case of breakdowns of the mechanical part of the CVT, a comprehensive diagnosis is carried out: an experienced specialist will identify and quickly replace the faulty components of the unit. You can install new components or choose refurbished used parts; the second option will cost much less.

Clutch adjustment

In addition, clutch adjustment is an important step. Typically, drivers do not associate a gearbox malfunction with the clutch, but they depend on each other. If the pedal begins to “fail”, it is necessary to urgently adjust it. By postponing the necessary actions, a person risks facing repairs.

If the clutch pedal fails, the transmission gears are not connected correctly. Accordingly, their wear increases several times. Over time, changing gears becomes difficult, and then the gearbox “falls apart.” As a result, major repairs are required, which will take several days. The reason for this is the lack of clutch adjustment.

Surely drivers don’t even imagine what difficulties arise when a gearbox breaks down. In the past, they were able to deal with faults on their own, but today professional services are required. Because of this, experts advise regularly visiting service centers for maintenance. Only such actions help to increase the service life of the gearbox, keeping its parts in excellent condition.

Related articles:

- SATELLITES IN THE TRANSMISSION Gearbox satellites - how do they work? We can say that it is not new, most likely it should be...

- AUTOMATIC TRANSMISSION Types and types of gearboxes (gearboxes) A gearbox (gearbox) is a mechanism that converts…

- HOW LONG DOES AN AUTOMATIC TRANSMISSION LAST? Summary: gearbox life, gearbox durability, how to reduce gearbox wear After several years of using the car...

- 6 SPEED MANUAL TRANSMISSION <backNEW 6-SPEED MANUAL TRANSMISSION MMT6Ford News 02/16/03 Ford releases a new six-speed manual transmission of premium quality…

Affordable car interior repairs

The main advantages of argon-arc welding include:

- high level of connection strength;

- presence of a neat seam;

- high speed of welding work;

- ability to operate on low currents;

- economically feasible price for the work done.

The price of welding an automatic and manual transmission of a car is affordable for our compatriots, and the quality is maintained at a high level. Become a regular customer of our company and don’t always waste your scarce free time.

Argon welding of a car gearbox has proven itself positively when repairing individual parts and assemblies in a car. This process will require the following components: specialized installations, argon and high-quality raw materials. After completing the work, there is no need to clean the seams from slag, and all parts will be securely connected. At the same time, the cut edges are protected from unwanted oxidation.

By performing work in accordance with a complex technological process, it is possible to restore the lost volume of parts that were already in use.

An automatic gearbox (abbreviated as AKPP) is one of the types of car transmission. The automatic transmission independently (excludes direct driver intervention in the process) sets the desired ratio of gear ratios, based on driving conditions and various factors. Engineering terminology recognizes as “automatic” only the planetary element of the unit, which is directly connected to gear shifting and, together with the torque converter, creates a single automatic stage. An important point: an automatic transmission always works in conjunction with a torque converter - it guarantees the correct operation of the unit. The role of the torque converter is to transmit a certain amount of torque to the input shaft, as well as to prevent jerking when changing stages.