Malfunctions of the automatic transmission valve body

There are several reasons why the automatic transmission valve body fails.

First of all, this is the result of improper operation of the transmission system. In particular, you should start driving in winter with warm transmission fluid. It warms up quite quickly. Thanks to this, the motorist will ensure high-quality cooling of the system. It seems possible to determine exactly the nature of the malfunction by dismantling the gearbox and then disassembling it. In this case, it is necessary to check the condition of the valves; in some cases, they need to be cleaned. Sometimes worn springs that are related to the valve body can be the reason why the unit is not functioning properly.

The fact that the automatic transmission valve body is broken may be indicated by the engine stopping when the “P” mode is activated to the “D” mode.

It should be noted that not every service center is ready to take on the task of restoring the operation of the automatic transmission or its individual components. This is explained by the fact that such an automatic transmission has a complex structure; repairing it is not a cheap undertaking. That is why some motorists decide to purchase a new gearbox, instead of replacing the automatic transmission valve body, to fix the problems that have arisen.

Automatic transmission valve body repair on Audi

The valve body of an Audi automatic transmission has some differences, in particular this concerns the process of installing the valve body. Once you take it off, be prepared for an average of about 200 mg of oil to pour out on you. It is necessary to remember the exact location of each of the screws that “install” the valve body, otherwise you risk performing the installation incorrectly, which will further affect the operation of the Audi car. Each of the bolts has a certain diameter, and there are practically no identical elements.

Automatic transmission valve body repair in many cases involves installing new elements, as well as thoroughly washing existing ones.

The valve body of an Audi car includes 60 bolts, 4 pistons, about 20 balls, as well as pins, etc. It is worth remembering which part was disassembled and in what order, because assembling the valve body can take much less time if you remember the sequence, or better yet, write it down, as soon as all the elements are replaced and installed back, the pan will also be installed, you need to fill in the oil , and if necessary, you can add a small amount with a syringe.

Design and purpose of the automatic transmission valve body

Causes of automatic transmission malfunctions and possible breakdowns

So, to put it simply, the valve body is a valve plate made of metal, in which many channels are made. These channels contain special valves (often called solenoids), as well as electronic sensors.

Taken together, these elements actually control the operation of the automatic transmission based on signals from the automatic transmission ECU. For this reason, it is common practice to call the hydraulic unit the “brain” of the box - an automatic transmission, since the hydraulic plate controls the operation of the automatic transmission.

As for the principle of operation, the automatic transmission valve body passes transmission fluid through the channels, that is, it transmits the pressure of the ATF fluid to the mechanical elements of the box. Thanks to this, gears are switched on and off automatically.

For each gear there are separate channels in the hydraulic plate. To engage a particular gear, a signal from the automatic transmission ECU is sent to the valves (solenoids), then the required valve is activated, as a result of which the channel opens, ATP fluid under pressure flows through the channel.

Next, the working fluid “presses” on the clutches, which, in turn, block the gear in the automatic transmission. This is how a stepwise change in the gear ratio occurs in an automatic hydromechanical gearbox.

Why and when is it necessary to flush the valve body of an automatic transmission?

Let's start with the fact that the most important element of the automatic transmission is the valve plate (valve block). Mechanics themselves often call this element the “brain” of the automatic transmission, since it is thanks to this device that they can achieve smooth and timely gear shifting in automatic mode.

In other words, the valve body is an actuator that controls the operation of the automatic transmission. The valve body itself (automatic transmission valve block) is a plate with channels through which transmission oil (ATF fluid) is supplied under pressure.

In fact, the oil activates the actuators, which “switch on” the desired gear. Also, the distribution of fluid flows is realized by installing special valves (automatic transmission solenoids) in the channels of the hydraulic plate. The valves open and close at the command of the ECU via the automatic transmission.

It is not difficult to guess that since the oil constantly circulates through the channels, over time wear products, small mechanical particles, deposits, etc. can clog the specified valve body channels or even damage them. The solenoids themselves also fail.

Such defects and malfunctions lead to the fact that the automatic transmission begins to push, jerks when switching, etc. At the same time, changing the oil in an automatic transmission is often not enough, especially if the oil is changed using a partial change. In other words, it may also be necessary to flush the valve body, as well as an understanding of how to flush the valve body of an automatic transmission. Let's figure it out.

Fault diagnosis methods

Chevrolet Cruze egemo Logbook Changing the automatic transmission oil

The main thing in diagnostics is to collect the necessary information and interpret it correctly. Therefore, it is better to contact specialists. Determine what the problem is at a service station, and do the repairs yourself. Without the proper experience and equipment, you will waste a lot of time on diagnostics. There is mechanical and.

General scheme of diagnostic procedures:

- check the oil,

- check the operation of the engine at idle speed, the connection points of electrical wiring and cables,

- determine error codes for the operation of transmission and engine control units (CU),

- check the box in a car without moving,

- check the automatic transmission while driving,

- check the pressure inside the control system.

Electronic control system and diagnostics of its malfunctions

If the cause of the malfunction is problems with the electronics, then most likely you will not need to dismantle and disassemble the automatic transmission. Diagnostics of faults in this system is carried out by the control unit. It monitors sensor signals, transmission ratios and output circuit resistance. Malfunctions of the following parts and assemblies may occur:

- input sensors,

- electronic control unit,

- control system actuators,

- violation of the integrity of electrical wiring connections.

The transmission computer receives signals from various sensors. If any parameters are abnormal, it stores a problem code (DTC) in memory. Such numbers can be deciphered using a special scanner.

Diagnosis of mechanical and hydraulic problems

These are the main problems of the automatic transmission itself. They are conventionally divided into three subgroups:

- Damage to friction groups, bushings and housings, calipers, planetary gears, pump and other mechanics.

- Transformer fault. This includes:

- broken wire splines,

- mechanical destruction of the blades,

- overrunning clutch,

- wear of the main locking clutch,

- depressurization of the piston seal.

- Problems with the mechanics of the hydraulic plate.

Signs of breakdown

The automatic transmission valve body is a separate unit that provides operating fluid pressure in the mechanical parts of the gearbox. Since this part of the automatic transmission is subjected to higher loads, the probability of its breakdown is several times higher than that of its other elements.

Usually it is the driver himself who is to blame if the valve body breaks down. This can happen due to non-compliance with the rules for operating the automatic transmission in winter or due to insufficient control over the oil level in it.

You can understand that the hydraulic unit has failed by the following signs:

- at the moment of gear shifting, a grinding noise occurs and vibration increases;

- when trying to switch between Parking and Drive modes, engine operation may stop completely;

- slipping, shocks and impacts are felt between gears;

- a message indicating gearbox damage appears on the display.

It is possible to identify the exact cause of a breakdown in modern cars with an electronic control system only after computer diagnostics. If the automatic transmission valve body really fails, then it will need to be dismantled and disassembled.

Automatic transmission dismantling

avtoexperts.ru Is the oil in the Kia Rio automatic transmission changed?

If the diagnosis was successful and dismantling is not possible, then we proceed to this stage of automatic transmission repair.

You will need a special lift, or at least an inspection hole. As well as a transmission jack and a set of keys. It is better to carry out this procedure in a specially equipped garage or box. It would be useful to invite several physically strong guys to help move the removed box. Its weight is beyond the strength of even a very strong person. Further plan of action:

- disconnect all communication tubes and cables;

- unscrew the torque converter mounting bolts, as well as the engine flywheel membrane;

- remove and move the gearbox;

- assess the extent of the damage and begin repairs.

All actions must be careful. Sudden movements can damage the splines of the diaphragm input shaft.

Automatic transmission valve body repair on Volkswagen

Automatic transmission valve body repair on a Volkswagen has a large number of features, unlike other foreign cars. Most often, the cause of all problems is insufficient lubrication of the entire mechanism, and this can happen because the oil level in the system is below the minimum. It is worth noting that repairing the automatic transmission valve body on this particular car will not be cheap, especially if this service is carried out in a car dealership.

If your car has an automatic transmission. It is famous for the fact that it can instantly fail, and the car is not able to continue the movement process, and one of the most common reasons is that the valve body fails, which requires immediate replacement.

Malfunctions of the automatic transmission valve body, causes of breakdowns

As you can see, the hydraulic unit distributes the flow of working fluid through the channels. Moreover, the ATF transmission fluid is supplied under pressure.

If the pressure is not enough, the automatic transmission stops working correctly, shocks and shocks appear when changing gears, and the automatic transmission kicks. The driver may also notice the appearance of strong vibrations, grinding, slipping of gears (slipping), delays between shifts, etc.

So, most often, automatic transmission valve body malfunctions are associated with the quality of the transmission oil and non-compliance with the operating rules of a car with an automatic transmission.

For example, dirty oil (ATP liquid) contains chips, wear products from the box, and also noticeably loses its properties. As a result, the valve body valves become contaminated, and scuff marks appear on the surfaces of channels, spools, couplings and other elements.

If we talk about the operation of the automatic transmission, overheating of the automatic transmission worsens the properties of the transmission oil, which also leads to valve body failure. The hydraulic unit also fails if the driver actively loads the automatic transmission (towing a trailer, accelerating sharply from a stop, slipping in mud or snow).

To extend the service life of the automatic transmission and valve body, it is necessary to promptly replace the ATF working fluid (every 50-60 thousand km), and also, if necessary, flush the valve body. The solenoids may also need to be replaced.

Valve body repair and automatic transmission fault diagnosis

Quite often, the symptoms and signs described above in the form of jerks and jolts of the automatic transmission indicate problems with the valve body. In this case, diagnosis must be carried out immediately.

The fact is that further operation of the box will mean that if the “automatic” operates with shocks, kicks and blows, such incorrect operation will cause the breakdown of other automatic transmission parts. The result is a significant increase in the cost of repairing an automatic transmission.

To carry out an initial check of the hydraulic unit, the box must be disassembled, after which the body plates undergo a so-called vacuum test. Such diagnostics allows you to determine the degree of wear of the element.

If necessary, the automatic transmission valve body is repaired or the valve body is replaced. In the case when repairs are carried out, first of all, after dismantling the hydraulic unit, the valve plate must be thoroughly washed. The remaining elements are also washed, the functionality of the valves (solenoids) is checked, the seals are changed, etc.

Valve block repair

Repair of the valve body at our Transmission Service Group (TSG) is always carried out only by highly qualified specialists. Let's consider the features of diagnostics and repair of automatic transmission and CVT valve bodies.

In an automatic transmission, the valve body performs the function of adjusting oil pressure and controlling transmission fluid flows, based on processing electronic signals coming from the control system.

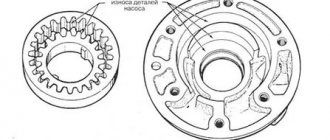

The valve body is a complex system consisting of two parts of the housing, pressure regulators, valves, springs, balls and other things. When repairing a hydraulic unit, the following are important: highly qualified specialists, the use of professional, precise equipment and tools.

At Transmission Service Group, these two conditions are met. Thanks to this, we repair hydraulic units in accordance with all quality standards established by the manufacturer.

The quality of work is always confirmed by an appropriate documented guarantee for the repair of the automatic transmission valve body.

Valve block repair - cost

Prices for automatic transmission valve body repairs start at 15,000 rubles

It all depends on the make and model of the car. A valve body malfunction is usually detected when computer diagnostics of the automatic transmission is carried out. Automatic transmission valve body repair consists of a number of sequential works.

When repairing automatic transmissions of any type: computer diagnostics free of charge

If you want to save more, then take a look at the “Days of Discounts and Promotions” page

Repair of valve body - sequence of work

- Dismantling the unit.

- Visual inspection and search for external defects.

- Disassembly and inspection of the device.

- Cleaning, washing, lapping of channels and valves.

- Installation of new electronic components.

- Installation of pressure regulator valves.

- Setting up a unit at stands.

- Testing the performance of hydraulic units on a car.

Valve body repair – 5 reasons to choose our car service

Experience working with automatic transmission hydraulic units since 2007

We work with valve body models from all current car manufacturers. During the work of our company, more than 15,000 orders for the repair of automatic transmission hydraulic units have been completed and enormous experience has been accumulated. Actually, we quickly find and fix all problems in any vehicle systems.

Competent diagnostics

Repair of the automatic transmission valve body, CVT, is carried out after a thorough diagnosis. This node is very complex and is the coordinator of all elements.

Therefore, you need not only to find problems, but also to understand the reason why they appeared. Thanks to competent diagnostics, you will not encounter problems in the future, provided that the unit is used correctly.

Hydraulic blocks and accessories for them

In our warehouse, we have in stock not only original components for automatic transmission valve bodies from manufacturers, but also the valve bodies themselves. Therefore, repairs and replacement of the unit are completely carried out without wasting time.

You don’t have to order and wait a long time for parts or an automatic transmission valve body from the USA or Europe.

Equipment from automatic transmission valve body manufacturers

Equipment with high technical characteristics recommended by manufacturers is used. This significantly increases the accuracy and quality of work.

Prices below market

Automatic transmission valve body repairs are always performed at an affordable price. Transparent pricing ensures that you don't overpay because you get all the information about the work done.

Valve unit design

- The valve body is a composite part made of aluminum alloy.

- Valves, regardless of their type, perform several functions in the valve body.

- Distribution of ATF transmission fluid flows.

- Switching control.

- Changing (adjusting) ATF pressure.

Operating principle of the hydraulic unit

The operation of an automatic transmission requires a certain internal pressure, which is created by an oil pump. The pressure created in the main line of the automatic transmission by the pump is used to control the clutches when the gear is loaded.

Smooth adjustment and maintenance of the required level of this pressure is carried out by pressure regulators. Immediately after starting the engine, the oil pump starts working.

The pressure regulator distributes the flow of transmission fluid by directing the required amount into the transformer feed circuit and into the transmission control system.

As the system fills with liquid, the pressure increases. The valve spring, which remains motionless until a certain moment, is activated when the pressure exceeds the permissible value.

Under the influence of fluid pressure, the spring gives way, opening the valve, and excess fluid is drained, which enters the automatic transmission pan. The pressure drops, causing the cycle to repeat.

Typical malfunctions of automatic transmission hydraulic units

- Malfunction of solenoids.

- Malfunction of the solenoid braid.

- Sensor malfunction.

- Clogged or worn valve plate.

- Failure of the electronic board.

You can find out the exact prices for repairs and sign up for free diagnostics and auto repair at any time. Take advantage of the communication option that is convenient for you, including free: all our contacts.

Call us, we will answer all questions related to the topic discussed in this material.

Sign up for a free diagnostic

The site is maintained by the express web studio KONTENT24.RU

You may also be interested in:

Prospects for using a hydromechanical gearbox

A very serious argument for machines with a hydromechanical “donut” is the relatively proven and perfect design of the device. Long service life, carefully selected hydraulic fluids and alloys for shafts and gears. With proper care and careful use, a hydromechanical gearbox lasts much longer than newfangled competitors in the form of CVTs, robotic or preselective DSG gearboxes.

Many experts believe that the hydromechanical transmission will remain a significant segment of passenger vehicles - SUVs and off-road vehicles.

Indirect confirmation of the fact that a gearbox based on a hydromechanical circuit will be intensively used for a long time in a wide range of passenger car models is the latest developments of automotive fashion trendsetters - German automakers. The well-known German company ZF has already launched a hydromechanical automatic transmission with 7 stages and record-breaking performance characteristics for almost all top models of BMW, AUDI and MERCEDES. In addition, the MERCEDES-BENZ concern has released its own version of a 7-speed hydromechanical gearbox called 7G-Tronic.

The reason for this popularity is quite simple and obvious. Indeed, in addition to reliability, the hydromechanical gearbox allows you to confidently work with high-power engines and with a displacement of more than three liters. The hydromechanical gearbox will disappear into oblivion no sooner than the internal combustion engine itself.

The video shows the structure of a hydromechanical automatic transmission:

One of the elements of the vehicle control system is a hydromechanical transmission. Thanks to it, the driver can change gears smoothly and without jerking. Hydromechanical gearbox - what is it? Let's figure it out.

For a car and similar vehicles, the transmission is the unit that transmits torque from the engines to the wheels. This is how it looks in cars with a clutch, but they are gradually being pushed out of the automatic transmission market. “Automatic machines” are installed more and more often today. They do not have a clutch, and gears change automatically. Fluid mechanics help make changing gears easier while driving. In classic gearboxes, the following processes are performed when driving a car:

- disconnecting the transmission from the engine at the time of gear changes;

- when road conditions change, the amount of torque changes.

To perform these actions, a hydromechanical automatic transmission is required. It simultaneously performs the functions of clutch and transmission. This box was specially designed for use in urban environments, where constantly squeezing the clutch can be problematic due to frequent stops in traffic jams. A car with hydromechanics is controlled using the brake and gas pedals.

Preparing to wash the automatic transmission

Before you start flushing the automatic transmission unit, you first need to take care of cleanliness. It is necessary to exclude the possibility of various specks and any third-party objects getting into the system.

You should immediately stock up on the following spare parts:

- oil filter for automatic transmission;

- oil pressure regulator;

- oil pan gasket;

- regulator gasket;

- filler plug o-ring.

Consumables:

- gear oil 12l;

- cylinder carb cleaner;

- gasoline 5l;

- rags.

Automatic transmission repair

It is better to carry out automatic transmission repairs yourself, having at hand the original manual and a printed diagram of the gearbox.

First you need to inspect all systems that service the gearbox, mounts and blocks. Then we begin the repair. For this:

We disassemble the gearbox, wash and dry the parts and check them for defects. We replace all gaskets, seals, and worn parts. Remove the inhibitor block and pan. We clean out the dirt inside. It looks like metal magnetic shavings. Remove the ring wires from the plug and push them inside the plug. Remove the valve body and loosen the brake band bolts. We wash the hydraulic unit. We check clutches, gears and planetary gears for wear. We replace it if necessary. All internal rubber bands must be changed! Open the oil pump. We check all the parts, especially the filter. We replace what has already served its purpose. We use the manual so as not to swap parts. We take out the valves and springs. We wash the valves. Their sticking may cause incorrect operation of the automatic transmission. We replace the accumulator springs if they are broken. Putting everything back in its place

It is important not to confuse anything! We replace rings and friction bolts. We check the gear shift assembly and the large piston and replace the oil pump.

Assembly occurs in reverse order.

There are certain points that it is advisable to take into account during repairs. Often the transmission problem is related to the filter. You won't be able to change it without removing the valve body. And when you remove it, the gasket breaks. To replace it, you will need to completely disassemble the valve body. The same applies to the accumulator spring from first to second gear. A special limiter does not allow it to be removed without disassembling the valve body. All valve body gaskets are very similar, do not mix them up. When assembling the valve body, we tighten it with a torque wrench

It’s important not to over-tighten here.

Two way valves

In a more complex case of line design, when it is necessary to control the transmission in two lines, two-way valves . When fluid enters (see picture) from the right line, the ball rolls into the left seat, simultaneously blocking ATF to the left line. From the open right line, the liquid is directed to the outlet line. When liquid enters through the left inlet line, the process with the ball occurs in the reverse order. The idea is again very simple, but you should look at the quality of the seats for the ball. The ball itself should not be slowed down by any risks, scuffing, etc.

The balls for such valves are usually made of steel. It is quite obvious that the wear resistance of steel balls is very high. However, to reduce the cost of construction, it happens that rubber, nylon or composite material balls are used. But I believe that such perversions, I apologize, are resorted to due to poverty. When making repairs, it is best to immediately replace such balls with steel ones.

Need for repairs

The function of the valve body is to redistribute the flow and pressure of the transmission. In order to prevent premature failure of the valve body, the driver must monitor the condition of the cooling system in the box. The valve body includes a valve plate and an electronic control unit

It is necessary to pay attention to the working condition of the sensors if slippage begins to be observed. There may be poor contact between the valve body and them.

Inside the valve plate there are channels with control valves, sensors, and solenoids. These elements are responsible for the operation of the high-speed gearbox. The need to replace solenoids arises after 80,000 km. With careful driving, this figure is almost 2 times higher.

Repairing an automatic transmission valve body with your own hands requires you to acquire a special repair kit, which includes materials such as rubber seals, for example, cuffs, clutches.

On a number of Volkswagen models that are equipped with an automatic transmission, restoration of the valve body can cost more than 40,000 rubles. To begin the repair, you should drain the fuel from the automatic transmission and remove the battery.

Thus, a common source of all problems with the valve body is the use of dirty oil. A specialized station may offer a procedure such as cleaning the valve body. Also, they will help with solving problems of overheating and disruption of the performance characteristics of board elements. All signs of a malfunction at the station are quickly identified.

Automatic transmission valve body and what is behind it

One of the main components of the automatic transmission, which affects the quality of the transmission, is the automatic transmission valve body. More than ten years ago, many mechanics who repair automatic transmissions introduced a slang word into the lexicon - brains. So don’t be surprised if you suddenly hear or read this definition on forums. Know that the brains are nothing more than the hydraulic control unit of the automatic transmission.

If we look very schematically at the automatic transmission as a whole, it consists of three interconnected parts: a clutch system (here we will not talk about where and how these clutches are inserted and other subtleties), a hydraulic control unit and an electronic control unit. These components are constantly being improved by manufacturers. Through dealers and nearby repair centers, statistical information is collected on failures and the specifics of these failures with subsequent modifications. Improvements are provided to technical centers in the form of technical replacement protocols. Technical center technicians monitor these technical replacements and carry out these replacements during regular or scheduled repairs.

The hydraulic control unit occupies the main place in organizing the flow of transmission fluid (ATF) and its access with the required pressure to all points of the mechanical part of the box. The block consists

as schematically shown in the figure from a system of valves, springs and balls, which also perform the function of valves.

Sectional view of the automatic transmission valve body

The block body is made of aluminum alloy and consists of several parts connected to each other. The valves are either purely mechanical or solenoid type. Let's remember the school physics course: applied voltage to the coil - the core retracted and blocked the channel through which transmission fluid under the required pressure is supplied to the right place, removed the voltage - the core with the valve returned to its original state.

Solenoids themselves are a rather capricious detail. The cost in Russia of one solenoid, depending on the manufacturer and type of box, can reach 30 - 50 Euro. The box may contain a solenoid unit, in

Automatic transmission valve body assembled

a set of which includes 4 - 6 solenoids. I remember a case when, about 10 years ago, a Volkswagen gearbox was being repaired, which had a defect in the solenoids. Spare parts suppliers at that moment did not have such a range of solenoids. We had to involve serious forces from Berlin. Of course, nowadays the processes for supplying spare parts have become quite simplified. However, for proper operation, solenoids must have certain electrical parameters, deviation from which can cause disruption in the operation of the automatic transmission.

Valves in the block are of four main types: pressure regulating, shifting control, distributing transmission fluid flows and smooth pressure control. It is clear that this composition may change in new boxes. Technology does not stand still.

Channels in the automatic transmission valve body

For example, in the recent past, the installation location of the valve body itself was only below in the box pan or on top (an old-style SAAB automatic transmission in which the box pan was on top!). But they began to install them vertically, such as on boxes for front-wheel drive cars. In a separate article we will look at the nuances of these settings.

So, since the hydraulic unit is responsible for redistributing the flow and pressure of the transmission fluid, you can easily guess that all the jerks and shocks that you suddenly begin to feel are primarily associated with problems that have arisen in the hydraulic control unit. But more on this in a separate article. If you have any questions, call right now and ask them.

Viktor Pavlovich +7 928 11 800 22

or Andrey +7 928 11 800 33

If you need repairs, it is better to call and go to:

Rostov-on-Don, st. V. Cherevichkina, 106/2

Good luck to you all and safe driving!

Shift control system

The small range of possible changes in torque and rotation speed forced the designers to supplement the torque converter with a manual gearbox. In a hydromechanical automatic transmission for passenger vehicles, several planetary gearboxes are used, which are activated using friction clutches. The clutch is engaged by compressing the friction lining package using a specially designed hydraulic piston.

The pump that powers the drive hydraulics is usually installed in close proximity to the torque converter. To control the hydraulic valves and spools of the system, modern cars use electromagnetic solenoids controlled by electronics. To compensate for shock contact loads, overrunning clutches are used, which adds smoothness when the gearbox gears engage.

For your information! Most modern hydromechanical automatic transmissions have the function of automatically turning off the torque converter when driving at speeds above 20-25 km/h. This makes it possible to significantly reduce losses associated with torque transmission, especially at high rotation speeds, when hydraulic losses grow faster than mechanical ones.

Hydraulic unit care

Hydraulic unit, inside view

With prolonged use of the vehicle, the transmission fluid gradually becomes contaminated. The result of this is the failure of the components of the gearbox.

When servicing the automatic transmission for the first time, it may be necessary to replace the solenoids and clean the automatic transmission valve body. This allows you to extend the service life of the transmission. The cost of repairing the hydraulic unit depends on the nature of the existing breakdown. Malfunctions of this device mainly occur as a result of overheating of the transmission and the use of dirty oil. Overheating of the gearbox leads to deformation of its parts, the valve body, the repair of which may involve replacing springs and valves.

What is dangerous about the presence of sediment in the form of metal shavings and combustion products in oil? The presence of these substances helps reduce the service life of the gearbox. In particular, filters and hydraulic system channels become clogged. The correct option in this situation is to flush the automatic transmission. Carrying out this procedure helps restore the stability of the transmission system.

In what other cases is flushing required? We list the main reasons for the need to clean the automatic transmission:

- gears are difficult to shift;

- the appearance of shocks during acceleration;

- instability of the functioning of the checkpoint.

If this procedure does not help solve the problem, it is advisable to order automatic transmission diagnostics, the results of which require disassembling the box and replacing worn parts.

Thus, the oil constantly circulates through the transmission channels; over time, wear products form in it, which clog the valve body channels. Because of this, the solenoids fail. As a result, the box begins to push when switching. A procedure such as flushing the gearbox can solve the problem.

Article on the topic: Gearbox for GAZ 53

Always in stock

| car model | Automatic transmission type | Note | Photo | Price |

| Audi | DL501/0B5 | 40000 RUR | ||

| Audi | 0AM/DSG7 | 18000 RUR | ||

| Audi | 01J | 24000 RUR | ||

| Audi | 09K/09G/09M TF 60SN/TF 61SN | Separator: E0,E1 A6,A7 | 37000 RUR | |

| Audi | 09 D TR 60SN | Separator: B5, B6, B7, G1, C1, A5, D1 | 40000 RUR | |

| Audi | 5HP19 01 V | Old style with speed sensor | 23000 RUR | |

| Audi | 5HP19 01 V | New model without speed sensor | 23000 RUR | |

| Audi | 5HP24 | 26000 RUR | ||

| Audi | 6НР19 09 L | Without solenoids | RUB 30,000 | |

| Audi | 6НР26 09 E | Without solenoids | RUB 30,000 | |

| Audi | 01M, 01N, 01P | 19000 RUR | ||

| BMW 1, 3, 5, X 3, Z4 | 6L45 6L50 | Without solenoids | 26000 RUR | |

| BMW 7, X5 | 5HP24 A5S 440Z | 26000 RUR | ||

| BMW | 6НР28 | Without solenoids | 34000 RUR | |

| BMW | 6НР21 | 34000 RUR | ||

| Cadillac SRX | 6L50 | Without solenoids | 26000 RUR | |

| Cadillac Escalade | 6L80 | Without solenoids | 26000 RUR | |

| Chevrolet Captiva | 55-50SN 55-51SN | 27000 RUR | ||

| Chevrolet/GMC | 4L60E 4L65E | Except HUMMER H | 18000 RUR | |

| Dodge Caliber | CVT JF011E | Without step motor | 25000 RUR | |

| Ford | 4F27 | 18000 RUR | ||

| Ford Escape, Mondeo, Contour | CD4E | Without solenoids | 18000 RUR | |

| Ford Galaxy, Mondeo, Fusion, S-Max | TF 81SC AF 21 | 35000 RUR | ||

| Hyundai Santa FE, Sonata, Tucson | A6LF1/2/3 | 23000 RUR | ||

| Hyundai Santa FE, Elantra, Grandeur, I30, Sonata | A6MF1/2 | 23000 RUR | ||

| Hyundai Avante HD/MD, Elantra | A6GF1 | 23000 RUR | ||

| Infiniti | JR710/711 | 34000 RUR | ||

| Infiniti | RE5R05 | Without electronic module and solenoids | RUB 30,000 | |

| Jaguar S-Type, XF, XJ, XK | 6HP26 | Without solenoids | RUB 30,000 | |

| Jeep Compass, Liberty | CVT JF011E | Without step motor | 25000 RUR | |

| Kia Sorento, Sportage | A6LF1/2/3 | 23000 RUR | ||

| Kia Forte, Grand Carnival, K5, K7, Optima, Sorento, Sportage, Soul | A6MF1/2 | 23000 RUR | ||

| Kia Forte, Pride, Soul | A6GF1 | 23000 RUR | ||

| Land Rover Range Rover | 6HP28 | Without solenoids | 34000 RUR | |

| Land Rover Range Rover | 5HP24 | 26000 RUR | ||

| Land Rover Range Rover Discovery | 6НР26 | Without solenoids | RUB 30,000 | |

| Land Rover Freelander | TF 81SC | 35000 RUR | ||

| Lexus LX 570 | AB60F | 40000 RUR | ||

| Lexus GS, LS, SC | A650E | RUB 30,000 | ||

| Lexus GX, LX | A750E | 40000 RUR | ||

| Lexus | A760 | 40000 RUR | ||

| Lexus | A960 | 40000 RUR | ||

| Lexus RX 300 | U140E/F | 23000 RUR | ||

| Lexus | U150E/F | 27000 RUR | ||

| Mazda | FNR5 | 19000 RUR | ||

| Mazda | 4F27 | 19000 RUR | ||

| Mazda 6 CX7, CX9 | TF 80SC AW 6AX-EL | 35000 RUR | ||

| Mercedes Benz Vito | 4HP20 | 20000 RUR | ||

| Mercedes Benz | 722.9 | Without electronic board | RUB 30,000 | |

| Mitsubishi | V4A51 | 18000 RUR | ||

| Mitsubishi Lancer, Outlander | CVT JF011E | Without step motor | 25000 RUR | |

| Mitsubishi Pajero, Montero | V5A51 | 18000 RUR | ||

| Nissan | RE4F03A | 18000 RUR | ||

| Nissan | RE4F04A | 18000 RUR | ||

| Nissan | V4A51 | 18000 RUR | ||

| Nissan Murano, Tiana | RE0F09A/B JF010E | Without step motor | 26000 RUR | |

| Nissan X-Trail, Qashqai, Tiana | CVT JF011E | Without step motor | 25000 RUR | |

| Nissan | RE5R05A | Without electronic module and solenoids | RUB 30,000 | |

| Peugeot 607 | 4HP20 | 20000 RUR | ||

| Peugeot | DP0 | 15000 RUR | ||

| Porsche Cayenne | 09D TR 60SN | Separators: B5, B6, B7, G1, C1, A5, D1 | 40000 RUR | |

| Saab 9.3, 9.5 | 55-50SN AF 33-5 | 25000 RUR | ||

| Saab 9.3 | TF 80SC AF 40/6 | 35000 RUR | ||

| Skoda | 0AM/DSG7 | 18000 RUR | ||

| SSang Yong | BTR78 | 40000 RUR | ||

| SSangYong Action | BTR M11 | 40000 RUR | ||

| Toyota | AB60F | 40000 RUR | ||

| Toyota | A760 | 40000 RUR | ||

| Toyota | U140E/F U241E | 23000 RUR | ||

| Toyota Camry, Matrix | U250E | 27000 RUR | ||

| Toyota Avensis, Celica, Corolla | U340 | 18000 RUR | ||

| Toyota Camry, Avalon | U660E | 29000 RUR | ||

| Volvo | 55-51SN 55-50SN | 27000 RUR | ||

| Volvo | TF-70 | New model hydraulic unit | 35000 RUR | |

| Volkswagen | 01M, 01N, 01P | 19000 RUR | ||

| Volkswagen | 0AM/DSG7 | 18000 RUR | ||

| Volkswagen | 09K/09G/09M TF60SN/TF61SN | Separators: E0, E1, A6, A7 | 37000 RUR | |

| Volkswagen | 09 D TR 60SN | Separators: B5, B6, B7, G1, C1, A5, D1 | 40000 RUR | |

| Volkswagen | 5HP19 01 V | Old style with speed sensor | 23000 RUR | |

| Volkswagen | 5HP19 01 V | New model without speed sensor | 23000 RUR | |

| Volkswagen | 5HP24 | 26000 RUR | ||

| Volkswagen | 6НР19 09 L | Without solenoids | RUB 30,000 | |

| Volkswagen | 6НР26 09 E | Without solenoids | RUB 30,000 |

Main causes of problems

Malfunctions of the automatic transmission valve body can be associated with a number of common reasons. First of all, this is unprofessional service. When the transmission is checked by qualified technicians, it may be discovered that the oil level was too low. This means that the oil was not added in a timely manner and its quality was not checked.

Experts can also identify:

Transmission overheating. This is a consequence of a violation of the automatic transmission valve body cleaning schedule. Oxidation of valves responsible for pressure and gear shifting. Solenoid failure. Contamination of the valve body with particles of dirt, dust, sealant, friction elements, that is, all the “garbage” that should get into the filter.

The heart of the hydromechanical gearbox

The torque converter of the box operates according to the scheme: “pump - hydraulic turbine” and provides, through dynamic oil pressure on the turbine blades, the transmission of torque to the gearbox shaft. The task of a pump or pump wheel is not much different from that used in centrifugal pumps: under the influence of centrifugal forces, to impart greater dynamic pressure to the oil flow. The wheel spun by the crankshaft flywheel throws a powerful oil flow at a certain angle onto the peripheral part of the outer part of the turbine rim - onto the blades of the turbine wheel. Under the pressure of oil, the turbine converts the energy of the oil into rotation.

The design of the gearbox torque converter includes another wheel with blades. A very important element is installed between the two main wheels - a special straightening apparatus called a reactor, or stator. It is made in the form of a ring with profiled blades that direct the flow of fluid leaving the hydraulic turbine to the inlet of the pump wheel.

Attention! As can be seen from the diagram, the flow of liquid thrown by the pump onto the turbine blades transfers part of the energy to it and then, turning around on the reactor guide vane, creates an additional torque, which causes an increase in torque. At first, when the car is just starting to move and the brake pedal has not yet been released, the reactor is completely blocked

We release the pedal, and the turbine of the hydromechanical part of the gearbox begins to work. When the turbine rotation speed reaches 80% of the pump wheel speed, the reactor is taken out of operation by an overrunning clutch. Thanks to a short-term and smooth increase in torque, the rotation speed of the turbine wheel and all associated transmission elements also occurs smoothly. With the use of a reactor, the torque on the output shaft of the torque converter at the moment of starting or accelerating the car increases to approximately two and a half times

At first, when the car is just starting to move and the brake pedal has not yet been released, the reactor is completely blocked. We release the pedal, and the turbine of the hydromechanical part of the gearbox begins to work. When the turbine rotation speed reaches 80% of the pump wheel speed, the reactor is taken out of operation by an overrunning clutch. Thanks to a short-term and smooth increase in torque, the rotation speed of the turbine wheel and all associated transmission elements also occurs smoothly. With the use of a reactor, the torque on the output shaft of the torque converter at the moment of starting or accelerating the car increases to approximately two and a half times.

Replacing the automatic transmission valve body

Replacing the automatic transmission valve body is carried out according to the standard procedure: it is necessary to remove the valve body and thoroughly rinse all its elements. Then assemble in the same order. If necessary, any valves can be replaced. Experts note that in 90% of all cases, the main problem is the oil filter, which is clogged to the maximum with waste products, and the cause may also be a cooling radiator that has failed for the same reason.

It is worth noting a number of features that should be taken into account when replacing an automatic transmission valve body on a Nissan. The filter cannot be removed until you remove the hydraulic unit, because one of the bolts has a nut located on the reverse side. But you can remove it, but you won’t be able to install it back. As soon as you remove the valve body, 80% of the fact is that the gasket will break, and to replace it you need to disassemble the valve body completely. In order to remove the accumulator spring, it is also necessary to completely disassemble the hydraulic unit, because You will need to remove one element, and this can only be done in a disassembled state. When installing the valve body in place, it can only be tightened with a torque wrench, because on Nissan, the tightening torques are very small, and there is a high risk of breaking them.

The cost of an automatic transmission valve body largely depends on which particular car model the procedure for replacing this unit is being carried out on, as well as on whether you will carry out this process yourself or entrust it to professionals.

Hydraulic block design

As already mentioned, the hydraulic unit is a link in controlling the movement of transmission fluid, pressure and access to the necessary points of the mechanical part of the box. The assembly consists of a housing, valves and springs. The block body consists of aluminum parts connected to each other. The valves located in the housing are either mechanical or solenoids.

The automatic transmission valve body solenoid valve, or solenoid, is an electromechanical device that regulates fluid flow. The composition includes a housing, a solenoid, with an installed disk or piston to regulate the flow. The solenoid is an electromagnet with a core installed inside; when voltage is applied to the coil, the core is retracted and closes the channel with the liquid. When the voltage is turned off, the valve returns to its original position.

Hydraulic block valve types:

- Pressure regulating valves;

- Valves that control switching;

- Valves that redistribute fluid flows;

- Smooth pressure control valve.

Design and principle of operation of solenoids: how does it work?

The hydraulic unit solenoids of a hydromechanical transmission are electromagnetic valves, the functional purpose of which is to adjust the position of linear lines. Solenoids are needed to regulate the pressure of the transmission fluid inside the box by opening and closing the passage channels, depending on the signals received by the ECU.

Structurally, each solenoid includes:

- A magnetic rod is a control element that, by changing its position relative to the hydraulic line, regulates the oil pressure in the gearbox. A copper winding and a return spring are fixed to the magnetic rod of the solenoid.

- Copper winding - the supplied electric current according to the ECU signals changes the electromagnetic field, causing the solenoid rod to move. The reverse process of opening and closing the solenoid occurs only when the electromagnetic force changes.

- Return spring – a tension spring that allows you to accelerate the return of the solenoid when an electromagnetic pulse occurs to close the hydraulic line. The presence of a spring ensures accurate and quick return of the rod to its original position, which prevents a decrease in vehicle dynamics and the appearance of jerks during gear shifts.

In the latest generation of solenoids, the magnetic rod is complemented by a steel core with a ball mechanism, which allows not only to open or close the hydraulic line channel, but also to regulate the pressure of the transmission fluid by limiting the capacity of the channel itself. A similar mechanism is called a three-channel solenoid and is installed on most modern automatic transmissions with 6 or more gears.

This is interesting! All automatic transmission solenoids are installed inside the hydraulic plate and are regulated by the electronic control unit of the transmission. The solenoids are connected to the ECU through a system of wires connected to the valve via a cable. In practice, the probability of failure of the loop itself is many times higher than failure of the solenoid itself. That is why the automatic transmission valve body is usually installed at the bottom of the box to facilitate its dismantling and repair without resorting to complete disassembly or removal of the gearbox from the car.

Strengths and weaknesses of fluid mechanics

The hydromechanical gearbox is a series connection of a transformer, a planetary unit with the clutches of a hydraulic control system. Its main advantage is that the driver does not need to change gears manually. The electronics do this accurately, so there is no discomfort when moving, and the engine is not overloaded. Their absence helps to keep it intact for a long time. When starting to move, power transmission also occurs without interruption or jerking, which makes the hydraulic mechanics more advanced, surpassing in its characteristics mechanical gearboxes. It’s not for nothing that they are used not only in the automotive industry, but also installed on tanks (in America and Germany).

The weak part of such an automatic transmission is the torque converter

The disadvantage of this mechanism is its high cost and technical complexity. When changing gears, you may notice a loss of performance due to slipping of the clutches and brake bands. The weak part of such an automatic transmission is the torque converter, due to which torque is lost. Despite the obvious advantages, the efficiency of hydromechanics according to measurement results is 86%, while for a conventional box it reaches 98%. Another drawback is the need to install a hydraulic unit cooling make-up system. They take up space under the hood, which is why the engine and transmission compartment is large. Also, cars with installed hydromechanics cannot be started by pushing or moving it on a cable. This type of box, as with all automatic machines, is characterized by the inability to regulate fuel consumption. The described version of the hydromechanical automatic transmission is one of the most primitive. Today, more advanced transmissions are being developed and installed on passenger cars produced in recent years. It is recommended to use hydromechanics for those who have recently gotten behind the wheel. For a beginner, it is indispensable because there is no need to change gears yourself.

Since the invention of the automatic transmission, the hydraulic unit has become an integral part of it, occupying an important place in the ranking. The clarity and correctness of the device’s functions affect the integrity and performance of the automatic transmission

It is not for nothing that mechanics consider this unit to be fundamental in the unit.

The hydraulic unit is part of the control unit, which is responsible for the actions of the box. Considering the number of tasks assigned to it, the mechanism is complex and, if a breakdown occurs, troubleshooting the unit will cost more than other components of the automatic transmission. Let's try to figure out what the automatic transmission valve body is, what is the role and operating principle of the device.

Mode selection valve

This valve is one of the main valves in the hydraulic control system of an automatic transmission . The valve is mechanically connected to the mode selector, which is installed inside the car. By moving the selector, the driver, through this mechanical connection, transmits to the valve an indication to select a mode. Each valve position is fixed by a special mechanism called a comb and is pressed by a spring retainer.

The mode selection valve of the automatic transmission valve body distributes the transmission flow so that the corresponding gear is engaged. It's simple. I hope that soon the operation of automatic transmissions will be thoroughly discussed and people in trouble will have fewer questions for the mechanics . Moreover, you will understand the essence of what is happening, and this is very important.

Torque converter device

The torque converter is placed between the engine and the mechanical part of the box. It consists of interconnected disks with blades. The first is the pump wheel, which is the drive wheel. It connects the motor and the transformer. The turbine is driven, it is in contact with the primary shaft. The reactor is responsible for increasing the torque. The turbines are practically drowned in oil (three-quarters immersed in it). They are covered by a housing that protects against foreign particles getting into the oil. During turbine operation, the engine torque is directed to the pump disc. At the same time, an oil flow is directed to the turbine disk under pressure. It is spun by a reactor wheel located in the central part. The resulting force is transferred to the gearbox shaft. The torque converter operates due to a special circulation of oil, which enters it from the outer part of the pump disk, then moves to the turbine wheel and returns through the central part of this unit. The oil circulation cycle on the pump disc is completed. The torque in the torque converter is replaced automatically as the engine load increases. This unit sends torque to the box, where the gears are engaged using clutches. The required gear ratio is determined automatically by the transformer; depending on its value, the pressure of the circulating oil changes.

Features of washing the “machine”

How to flush an automatic transmission? It is recommended to carry out this procedure in specialized auto repair shops that have the necessary equipment and washing machines. Flushing the gearbox allows you to remove dirt deposits.

If the car owner decides to wash the automatic transmission with his own hands, he needs a new transmission, a set of wrenches, polygons, screwdrivers, and a washer. Also, rags and empty containers are needed.

Washing algorithm:

- The machine must be driven into the inspection hole, after which the liquid must first be drained into an empty container.

- Next, a device is connected to the box, through which new transmission oil will be added.

- The engine starts (for about 15 minutes).

- The device creates pressure, due to which the oil passes through the channels of the automatic transmission hydraulic system.

- The transmission is drained.

- The filter element and pan gasket need to be replaced.

- New oil is added.

Finally, the operation of the transmission system must be checked and the engine will start. In normal condition, there should be no extraneous noise during operation. The amount of fuel spent on this procedure depends on the gearbox model (approximately 10-15 liters).

Flushing the automatic transmission can be carried out simultaneously with a complete change of transmission oil. It should be noted that a number of car owners decide to wash the automatic transmission with diesel fuel.

How to flush the automatic transmission valve body?

Cleaning/flushing the automatic transmission valve body occurs as follows:

- This device is removed from its regular place, and then disassembled.

- Especially for this, the oil is drained, the pan, plug, and connector adapter are removed.

- Next, the block, the fixing elements of the board, and the rods are unscrewed.

- After disassembly, all components must be cleaned and washed with a special aerosol designed for cleaning the carburetor.

- Finally, the parts should be wiped with a clean cloth and dried.

Article on the topic: Changing the oil in the transfer case and gearbox of a Chevrolet Niva

Installation of components occurs in the reverse order.

Important! After the valve body has been installed in place, a new layer of sealant should be applied to the crankcase and the pan gasket should be replaced. After this, fresh automatic transmission fluid is added.

Signs of hydraulic unit malfunction, symptoms

The first sign that indicates a malfunction of the hydraulic unit appears during operation of the automatic transmission. Symptoms of a malfunction are strong vibration and crackling noise when shifting gears. In severe cases, the power unit stops working when the box switches from mode to mode. As a rule, this happens when switching from Parking mode to Drive mode. Frequent confirmation of malfunction: shocks, impacts and slipping.

Modern vehicles are equipped with sensors that display information about a breakdown in the form of a code on the on-board computer screen. To make an accurate diagnosis and identify a breakdown, the car’s on-board computer is connected to a diagnostic stand designed to test the functionality of the valve bodies. Carrying out automatic transmission tests will identify the faulty element. Detailed information about the failure is obtained after removing and completely disassembling the valve plate.

Self-repair – is it possible?

Some owners, wanting to save money, try to repair the hydraulic unit themselves. Remember that an automatic transmission is a serious and complex device, the repair of which requires practice and skill. To perform the work properly, you must have at least an idea of how automatic transmission valve bodies are repaired. Mistakes made during self-repair will lead to irreparable consequences, as a result, more is lost.

Repair of the automatic transmission hydraulic unit includes the following steps:

- Diagnostics, determination of scope of work;

- Removing the valve plate from the box seat;

- Flushing the automatic transmission valve body;

- Inspection and determination of the performance of solenoid valves;

- Identification of parts to be replaced;

- Restoration of control valve block;

- Valve plate assembly and calibration;

- Installation of the slab on the workplace.

The correct decision to replace the solenoid valves is made by a specialist. Solenoids with slight contamination are restored, after which they are able to work for quite a long time. It is better to replace severely damaged solenoids, since restoring them will cost more than buying new ones.

Repairing a hydraulic unit is a difficult task for an inexperienced user, however, it is possible to dismantle it yourself for the purpose of replacement or cleaning. Moreover, the operation does not require complex manipulations and saves money.

Removing the hydraulic unit:

- Drain the transmission fluid from the box;

- Remove the battery;

- Disconnect the solenoid valve connectors;

- Unscrew the fastening bolts;

- Remove the hydraulic block.

Cleaning the automatic transmission valve body:

- Unscrew the hydraulic block bolts;

- Remove the hydraulic block cover;

- Remove the filter and solenoid valve of the hydraulic unit;

- Clean the hydraulic unit and parts;

- Reassemble the hydraulic unit in reverse order.

It is recommended to clean the mechanism with a special washing liquid or carburetor cleaner. Installation of the valve plate is carried out in the reverse order of dismantling. Before installation, it is recommended to change the sealing gasket; assembly is carried out carefully and carefully, followed by checking the correct gear shifting.

After installing the hydraulic unit in place, pour 4 liters of transmission fluid into the box, preheating it to 50-60°C. We start the car, set the automatic transmission to park mode and, with the power plant running, unscrew the fluid level check plug. If the oil flows in a thin stream, the order and level are acceptable. If it drips or does not flow, you need to fill in half a liter of lubricant and repeat the control procedure.

Service life: how long do they last and when is it time to change automatic transmission solenoids?

The service life of solenoids in the valve body of an automatic transmission directly depends on the quality of the transmission fluid used and the intensity of use of the vehicle. Failure of the solenoids occurs either as a result of overheating of the automatic transmission, which leads to damage to the connection cable between the sensor and the ECU, or as a result of clogging of the ball mechanism with wear products of the box as a result of severe contamination of the ATF oil.

If the regulations are followed, replacing the transmission fluid in the box at least once every 60,000 km and flushing the automatic transmission valve body is required every second maintenance. If there is no complete flushing of the valve body after 100-110,000 km, the service life of the automatic transmission is reduced by half.

When should you contact the service?

The plate itself rarely receives mechanical damage; valves and sealing elements fail. Because of this, the required pressure is not created in the channels, and the device ceases to perform its tasks correctly. If you notice changes in the operation of the automatic transmission, you should immediately contact the service. A comprehensive diagnosis of the automatic transmission will show what problems in this unit need to be eliminated.

The main manifestations of hydraulic plate problems:

- grinding, other unpleasant sounds that occur when changing to the next gear;

- a push or kick when engaging first or reverse gear on a car;

- slipping - after engaging the gear, the engine speed rises, but the car does not move;

- a corresponding message on the on-board computer screen indicating problems with the gearbox;

- An oil leak under the machine after the car has been parked in place for 5-8 hours.

If you feel the symptoms described above, it is important to contact the workshop in time. The diagnostic service will clarify the problem and show ways to resolve the problem. Continuing to drive with a failed unit will completely destroy the expensive unit. The cost of repairing an automatic transmission valve body will not be low; it is a complex, comprehensive process. But the cost of restoration is not comparable to the price tag of a new transmission for your car.

Why does a part fail?

Typically, a breakdown develops due to the failure of solenoids - valve mechanisms. They do not allow transmission oil to pass through well, which is why the pressure regime is disrupted and the device begins to operate in unusual modes. Cars often come to repair automatic transmission valve units in Moscow after replacing the oil in the gearbox with a non-original one. You need to be careful about the quality of lubricating fluids, otherwise problems cannot be avoided.

Problems also arise if you have not changed the oil and oil filter in the machine for more than 100,000 km. Even if the manufacturer does not recommend replacement, it is worth carrying out regular maintenance.

A technician in Moscow carries out diagnostics and repairs of hydraulic units and mechatronics:

⦁ Mechatronics DSG, DCT, ⦁ Multitronics, ⦁ CVT transmissions, ⦁ Automatic transmissions ⦁ Robotic gearboxes

A hydraulic malfunction in a chain reaction disables the gearbox itself, so greater attention should be paid to the diagnosis and repair of this device. You can detect the breakdown yourself - if there are certain problems in the valve body, the movement of the machine is characterized by jolts, gear failures, and slipping. A harsh and uncomfortable ride is the first sign of problems.

If a malfunction is discovered, you should immediately contact specialized specialists. To understand the design of the valve body, you need enormous experience. Not every automotive equipment repair company deals with such components, and it is also not recommended to repair the unit yourself. The automatic transmission valve body is a complex assembly that uses many parts such as plungers, springs, valves, solenoids, sensors, balls, filters, clamps, adjusting screws, washers and certain gaskets. To understand the design of the valve body and find a breakdown, serious experience is required. Work may be hampered by a crack, an increased gap between the body and the plunger, a violation of the position of the adjusting screws, or other malfunctions that are invisible to the inexperienced eye.

Many people, out of a desire to save money, try to clean the valve body themselves. Remember that the price for repairing an automatic transmission valve body is much lower; if there was no intervention, all spare parts remain original. If you use low-quality analogues that are not properly adjusted, the number of breakdowns may increase noticeably. Cleaning them yourself is not easy, since you need special tools and some equipment. If the valve body is assembled incorrectly after repair and washing, the valves on their working surfaces in the hydraulic module may be destroyed and, as a consequence, the automatic transmission may break down. Also, during operation, solenoids and plungers may wear out, springs may weaken or break. If necessary, a high-precision measuring tool (Valve Body Tester—Electronically controlled hydraulic diagnostic stand) is used to determine the degree of wear. Therefore, automatic transmission valve body repairs should be trusted to specialized car services that have restoration experience and the necessary equipment.

Automatic transmission valve body replacement in Moscow

Replacing the valve body of a vehicle's automatic transmission is carried out in the event of serious damage to this part of the unit. Most often we are talking about mechanical defects. For example, when cracks appear in the slab structure. Some service providers, of course, offer restoration, but, as practice shows, such actions will have a very short-term effect. Large loads exerted by pressure and temperature changes will soon lead to the need to repeat the procedure. Therefore, due to the peculiarity of the operating conditions, in this case the valve body should be replaced. Of course, the price of this operation may be higher, but it is precisely this that will allow you to continue to operate the automatic transmission in normal mode.

Automatic transmission elements

Being a complex unit, an automatic gearbox is much more demanding in terms of maintenance and operating conditions than its mechanical counterpart. For example, the working composition must be replaced every 30-40 thousand kilometers. Otherwise, wear products will clog the oil pump and damage it. Consequently, it will be impossible to provide the required pressure and, as a result, the operation of the gearbox will be interrupted. Leaks of working material are also common. The gaskets that ensure tightness cannot withstand the load and begin to leak liquid out. Such defects must be monitored in time until the oil level drops to the minimum level.

The valve body is considered one of the main elements of an automatic transmission. The working fluid passes through the channels located on its surface, moving to the desired clutch package to change gears. The process is controlled by an ECU, which controls a system of solenoid valves that open and close the channels needed at the moment. Note that the strong interconnection of elements leads to failures of the entire system if even one component fails.

Recovery operations

If it has been decided that it is necessary to replace the automatic transmission valve body of a car, you should purchase the necessary part. Note that such operations are most often relevant for older cars, so we are not talking about purchasing new parts of this type. Therefore, to purchase the necessary spare parts, you should contact suppliers of used elements. Let us note that there are quite a few auto repair shops operating in Moscow, but the selection of parts should be done with great care.

Let's look at the process:

- Oil drain

- Disconnecting wiring

- Removing the pallet

- Removing the valve body

- Installing a new part

- Assembly

- Pouring new material

- !Important! At the same time, it is worth cleaning from contaminants. Also replace seals and gaskets.

- Where to go?

You should not trust the replacement of an automatic transmission valve body to unverified servicemen. This procedure is very complicated, so the participation of amateurs is not allowed. Find a technical center that has automatic transmission specialists on staff. For example, you can use, which also deals with automatic transmission repair. Consequently, all necessary operations will be performed with a guarantee of quality and on time.

Related faults

Failures are often combined - in addition to the gearbox, diagnostics are also carried out for other components. Automatic transmission valve body repair in Moscow is done in one day at best, but if there are several faults, it is better to do all the work at once, even if the time increases. The following parts are actively worn out:

- solenoids;

- springs;

- plungers;

- valve body body

High-quality repair of hydraulic units in Moscow is possible only in a specialized car service center, where there are experienced mechanics and the necessary equipment.

Safe operation of the vehicle is only possible when all systems are in working order and functioning properly.

Automatic transmission valve body repair

The valve body (control valve plate, hydraulic module) – if it becomes faulty, being one of the central components of the gearbox, it can lead to problems in other components. A failure of the valve control plate can result from an inappropriate oil change, resulting in overheating of the automatic transmission. Such a defect will be felt while driving in the form of shocks and slipping when changing gears.

Are there any jerks (jokes) when changing gears?

In this situation, prompt repair of the valve body is carried out in order to avoid subsequent replacement of the entire gearbox. Experience shows that the hydraulic module is most often the first to become unusable, sharply increasing the risk of breakdown of the remaining automatic transmission units. Thanks to innovative equipment from dealers, our technical center is able to provide qualified assistance in solving this problem.

In the language of specialists, the hydraulic module or hydraulic unit is called the “brains”. At one time, this central module determined the order in which automatic transmission units were put into operation, which is why it received its name. Today, their role is played by an electronic control unit consisting of solenoids, electronic board models and solenoid valves. Thus, by combining an electronic monitoring and control module with a hydraulic valve plate, manufacturers have intelligent control and control of the entire transmission.

In addition, solenoids often fail. Diaphragms and internal o-ring seals installed on solenoid blocks are subject to overheating along with the entire transmission. An acute question arises: does it make sense to disassemble the entire transmission for these parts? Mechanical wear and adjustment.

Mechanical wear and adjustment.

Measuring stands offered on the market are not always able to detect mechanical wear of the ball located in the valve seat, as well as the seat itself. The ball located in the valve seat is necessary for oil passage. However, when worn out, the ball fits into the seat with a distortion, ceasing to perform its function. The calibration of the screw on the back of the solenoid can also cause a malfunction. The manufacturer himself carries out this calibration to install the valve. If the pressure changes (increases or decreases), you use the adjusting screw and select the required indicators. Operational differences between the solenoids in the photo:

Solenoids are classified according to their purpose.

The most common functions of solenoids are: - EPC or LPC (Line Pressure Control) solenoid. Line pressure monitoring solenoid, the first and main one in the valve body. Its function is to distribute fluid to other solenoids, so in four mortars it was the first to become unusable.

— TCC solenoid — Torque Converter Clutch. (or SLU - Solenoid Lock-Up - clutch locking) Torque converter locking control solenoid. Its task is to block the torque converter clutch to sharply increase efficiency and carry out the “sport mode” acceleration command.

Its frequent breakdowns are due to the fact that it passes through itself the main flow of hot oil, which contains large fractions of dirt and additives from the torque converter. The torque converter reacts to braking or acceleration by blocking or unlocking, its clutch operates in the “corrected slip” mode, at the moment when the torque converter begins to heat up the oil more strongly and clogs the friction lining. Unfortunately, there is a tendency to add Kevlar or graphite connecting elements, which have an extremely negative effect on the solenoid itself.

photo

— Shift solenoid — the shift solenoid regulates the pressure and is responsible for shifting gears.

Usually it is duplicated in the valve body, so the main job of shifting gears falls on them. On block diagrams they are marked with code A,B/S1,S2/SL1,SL2 Repair of the valve block consists of the following steps:

1. Unmounting and installation of equipment.

2. Intensive cleaning of the automatic transmission valve body and valve analysis.

3. External inspection of the hydraulic module to detect obvious inconsistencies and unacceptable backlash.

4. Using vacuum equipment to measure the hydraulic module.

5. Diagnostics of solenoids with electronic equipment for defects in operation.

6. Replacing inappropriate solenoids and normalizing the operation of components.

7. Replacing damaged line pressure solenoids with serviceable ones.

The authorized technological service center ATCMGROUP diagnoses and repairs hydraulic modules and mechatronics:

— Mechatronics DSG,

— Multitronic,

— CVT transmissions,

— Automatic transmissions

— Robotic gearboxes

How to recognize a faulty automatic transmission valve body?

For the driver, characteristic signs of such troubles are high vibrations and grinding noise, which can be noticed when switching from one gear to another. In some cases, the engine may stop when changing the “parking” mode to the “drive” mode. The driver notices shocks, impacts and slipping when changing gears.

New car dashboards often have an option to alert the driver to transmission problems. Further clarification of the breakdown and methods for its localization are determined by computer and mechanical diagnostic methods, as well as by dismantling and disassembling the unit.